Fall Semiconductor Series: How integrated software and automation transform fab sustainability

(Part 5 of 5): Why smart manufacturing is the key to synchronizing software, data sets and automation

In our Fall Semiconductor Series, we discuss the sustainability challenges faced by semiconductor fabs and why an integrated software and automation solution is the right solution to address these challenges. If you missed our earlier posts, just click on Part 1 , Part 2 , Part 3 or Part 4 of the Series.

In Part 5, our final post in the Series, we focus on why smart manufacturing is the key to synchronizing software, data sets and automation.

Smart manufacturing integrates digital technologies, advanced automation, and data analytics to create intelligent, connected systems that continuously learn, adapt, and optimize production performance in real time to drive fabrication excellence.

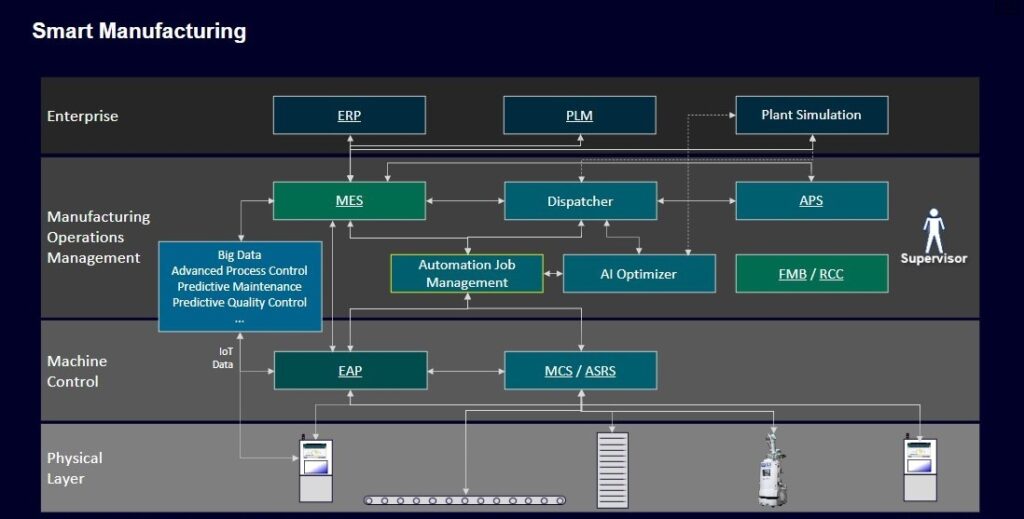

Software is the backbone of smart manufacturing. It connects disparate systems—ERP, MES, PLCs, IoT devices—into a unified ecosystem (outlined in the diagram below) for seamless communication across design, production, quality, and supply chain disciplines.

In a semiconductor fab, sensors, machines, and automation collect real-time production data, but software transforms that data into actionable intelligence. Which elevates your operation from a collection of machines into an intelligent, self-optimizing system—true smart manufacturing.

Predictive maintenance and AI optimization

With smart manufacturing, your fab can optimize production to achieve operational excellence. Yield optimization results from real-time monitoring that detects process deviations instantly to prevent defects before they can occur. Predictive maintenance becomes the norm, identifying equipment failures before they happen to minimize unplanned shutdowns. Faster cycle times are made possible by intelligent scheduling and resource allocation to optimize fab throughput and reduce time-to-market.

Energy optimization, waste reduction, water conservation and reduced environmental impact improve both sustainability and profitability. And intelligent systems adapt quickly to new process recipes and product mixes to help you stay ahead.

With end-to-end visibility—from design through fab production to subfab performance—you can access the real-time data and insights needed to make faster, smarter decisions.

Reactive troubleshooting transforms into proactive optimization, unlocking hidden efficiencies, while identifying opportunities for sustainability improvements at every step:

- Catch quality issues early and ensure flawless product consistency

- Collaborate seamlessly across all disciplines with robust data management

- Evolve from reactive to predictive to prescriptive maintenance to prevent downtime

- Analyze sensor, actuator and I/O module data from your equipment

- Anticipate potential problems and schedule maintenance before production disruption

- Improve process efficiency for rapid adjustments to optimize parameters and yield

- Meet quality and sustainability KPIs while optimizing resource and energy management

Future proofing your fab

For operational excellence, you need to harness the power of software-enabled automation to continuously optimize and adapt your semiconductor production to reach new levels of sustainable performance.

The combination of intelligent automation and machine learning algorithms enables fabs to detect and correct process variations in real time, dramatically reducing defect rates while maximizing yield. Furthermore, these smart manufacturing and automation systems provide the flexibility to swiftly reconfigure production lines, enabling fabs to seamlessly pivot between product specifications and adapt rapidly to market demands, which is a crucial competitive advantage in today’s fast-paced semiconductor industry.

In addition, smart manufacturing equips semiconductor fabs to make a next-level transformation using a strategic deployment of advanced robotics and AI-optimized systems.

These sophisticated technologies not only enhance manufacturing precision down to nanometer-scale accuracy but also elevate consistency across production runs.

Work smarter by working together

By integrating software and automation, Siemens smart manufacturing solutions enable semiconductor companies and equipment manufacturers to achieve greater productivity, improve new product introduction (NPI) yields at higher initial quality, enhance production sustainability, grow your business and stay ahead of the competition.

Siemens is ready to be your partner with unparalleled experience in end-to-end solutions in semiconductor manufacturing, automation and sustainable solutions. We’re committed to helping your company reach your sustainability goals.

The Siemens mission is to ensure that you have a successful business outcome from your smart manufacturing and digital twin investment as part of the Siemens Xcelerator business platform of software, hardware and services.

Read the eBook, “Using integrated software and automation to transform fab sustainability.”

If you’d like to explore more about integrated software and automation, download our new eBook, “Using integrated software and automation to transform fab sustainability.”