Harness digital transformation to collaborate seamlessly across platforms

Mandar Lele – Industry Expert in Digital Transformation @Siemens Digital Industries Software | Electronics | Digital Twins | PLM | NPI | Supply Chain | Sustainability and Compliance

Post 1 of a 3-Part Series.

Today’s rapidly evolving global electronics market gets more demanding every business day. Customer demand for complex electronic products with more features, functionality, and options is surging. At the same time, customers expect these exciting enhancements to be widely available and easily affordable.

Manufacturers are increasingly challenged to develop and deliver today’s complex products using outdated tools and systems. To create the next generation of electronics, they need greater collaboration and innovation across their design and engineering teams—something legacy solutions simply can’t provide. Unfortunately, many legacy systems still in use today are fragmented, operating in silos without a unified data platform or a shared language across systems. This severely limits the collaboration needed to drive the development of next-generation electronics. It’s clear that a new approach is essential—one that fosters seamless collaboration, enables continuous innovation and accelerates development cycles to meet the demands of the modern electronics market.

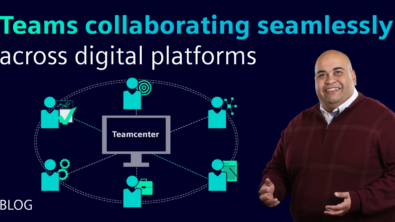

Digital transformation connects and empowers design and engineering teams

The key is digital transformation – providing accelerated access to project, product, and process data – including change management – which allows all the teams in your organization to collaborate earlier to make quicker data-driven decisions to go to market faster.

Fortunately, modern Lifecycle Management (PLM) software can provide the end-to-end digitalization needed, with a digital thread backbone connecting applications, people, and processes throughout the product lifecycle.

In the fast-paced world of consumer and industrial electronics, how you manage your product’s data, programs, requirements, and quality makes all the difference. When these priorities are not managed effectively, they impact your team and competitiveness. It means delays in getting products out the door, higher costs, or customers losing trust, all of which signal the need for change.

Seamless collaboration doesn’t just happen – it must be designed into the process

During the New Product Introduction Process (NPI), as data flows downstream for manufacturing, supply chain planning, compliance, and costing become more complex. As products become increasingly complex, collaboration across various engineering teams—mechanical, electronics, electrical, packaging, and software—must be seamless so that innovation can be continuous.

Some popular software solutions offer helpful features, but collectively, they don’t solve the big challenge of integrated collaboration. Social collaboration platforms like Slack and Webex help facilitate part of the solution with cross-team communication but fall short of a total solution. Similarly, popular office products such as Microsoft Office & Google Docs provide real-time collaboration for documents but don’t go far enough to empower the whole team to work better together.

Fortunately for OEMs, Siemens Xcelerator offers a new level of seamless collaboration for the entire team with interoperable tools to accelerate innovation throughout NPI programs. Siemens Xcelerator offers PLM software that provides a specialized, integrated approach for managing the complexities of product development. It ensures that all data, processes, and teams involved in electronics development will stay aligned as the product is developed.

Seamless collaboration is now an imperative for business essentials:

• Product roadmaps, programs and schedules to align strategic goals, user requests, work in progress and resource optimization.

• Product and process data management – managing design, engineering, manufacturing, service, and planning bill of materials (BOM).

• Change Management processes – initiating, tracking, and managing change. This includes critical communication with downstream applications and contract manufacturers about BOM changes during NPI.

• Requirements and verification management – start compliant and stay compliant. By integrating requirements and verification management, you can build confidence in every aspect of your final product, ensuring unmatched quality, traceability, and compliance.

When you combine all these advantages in a single collaborative product lifecycle management solution, with all product and process data; you’re not just managing, you’re orchestrating a seamless, customer-centric journey from concept to market.

It’s a win-win. For seamless collaboration. And new product success.

To learn more about digitally transforming your business, I invite you to view our webinar – Digital Transformation—Don’t Just Replace—Dramatically Improve!