Shifting left for success in smart semiconductor manufacturing (Part 1 of 3)

Our first post in a three-part series on Smart Semiconductor Manufacturing begins with a shift left. Learn more about what shifting left means and how to build a digital twin ecosystem across an enterprise.

Shift left in semiconductor manufacturing

You have heard that time is money. That is the premise behind the concept of shift left. The sooner you can verify your product and validate your manufacturing process, the better. The cost of change and investments are generally cheaper earlier in the product lifecycle than later, making the ability to change all that much easier.

Model process improvements with a digital twin in semiconductor manufacturing

A digital twin is a virtual model of an actual process, product or service occurring in the physical world. In the semiconductor design realm, a digital twin has been used for decades to simulate and validate chip designs to achieve one of the crown jewels – first time right products. That includes the correct process capabilities because a process design kit (PDK) in one fab may not work in another fab. And the digital twin is not static – it is constantly being updated with real-world data.

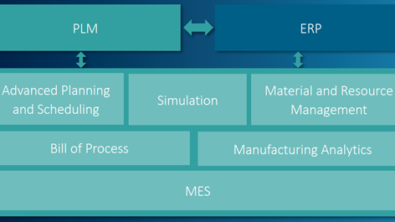

Optimize the entire enterprise with a digital twin

When you weave together more than one digital twin, you get a digital thread across the enterprise. The digital thread for a product lifecycle enables organizations to design and build anywhere at scale, while unlocking insights into rapid product and process optimization. It helps to connect the entire lifecycle of the product through all its phases – design, manufacturing, testing, qualification and managing the product after delivery to the customer.

What more can smart manufacturing do to boost your semiconductor business?

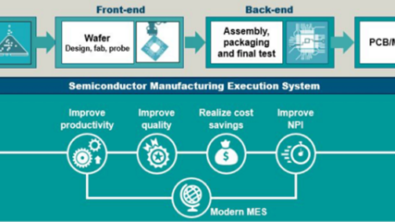

In our next post, we discuss the advantages of Smarter Semiconductor Manufacturing Execution.

Download our informative ebook “Digital transformation for smart semiconductor manufacturing” authored by Fram Akiki, M.B.A., President of Joun Technologies, a leading consulting group focused on digital transformation and smart, connected strategies, and an adjunct professor at Clarkson University and Cal State.

Blog written by Melville Bryant, Siemens Digital Industries Software