Don’t erase profitability with errors in high-mix, low volume PCB manufacturing

Getting ready for mass personalization in PCB manufacturing

Is your production process ready for mass personalization to replace mass production? Businesses need to rethink how they design, package, manufacture, and deliver printed circuit boards to meet the market’s new high-mix, low volume needs without erasing profitability with errors.

Valor Process Preparation creates a single, central database of all manufacturing process definitions and engineering data. Acting as a single environment for all manufacturing process stages, Process Preparation ensures data is constantly up-to-date and an error-free manufacturing process.

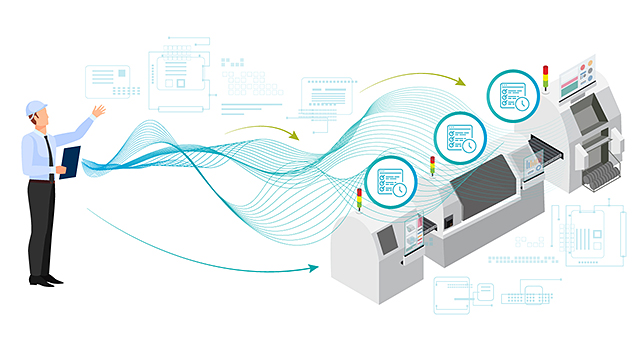

How does a PCB digital twin work?

The PCB digital twin methodology provides:

- A full virtualization of the PCB assembly process.

- Providing access to fully synchronized data across the enterprise.

- Reducing the probability of errors on the shop floor and improving both production yields and the bottom line.

You can see how SRXGlobal uses Process Preparation to automate and simplify the stencil customization process, resulting in shorter lead times and reducing costly defects that can erase profitability.

Benefits of a digital twin for PCB Manufacturing

Some benefits of developing a PCB digital twin include:

- Early discovery of issues allows the decision-making process to shift leftward, helping reduce expenses since you get it right the first time

- Data backbone synchronization ensures engineers across the enterprise access to up-to-date, in-process design data

- The centralized knowledgebase of engineering changes shared among all manufacturing sites

- Improves manufacturing agility, reduces cost and accelerates time-to-market

Streamline your next run of high-mix, low volume PCBs

Valor process engineering solutions simplify the delivery of high-quality, consistent surface mount technology (SMT) process collateral, empowering you to meet the engineering demands of high-mix, low-volume production efficiently.

Learn more about Valor Process Preparation and discover how you can reduce errors, lead times and innovate faster.

Want to give it a try today? Sign up for a 30-day trial of Valor Process Preparation to unlock an immediate, hands-on trial.