Why the engineer’s design journey is becoming the new competitive battleground

In electronic systems design, the way engineers evaluate and adopt components is undergoing its biggest shift in decades. That shift — and the opportunity it creates for semiconductor and component manufacturers — is the central focus of my new Siemens white paper, “Rethinking the design journey: Why design enablement is the future of component engagement.” The paper highlights how rapidly growing design complexity, expectations for immediate digital engagement, and broken workflow handoffs are reshaping the relationship between engineers and the component brands they depend on.

This blog explores one of the paper’s core themes: the design journey itself has become the new battleground for competitive advantage.

The problem: Digital fatigue meets design complexity

As detailed in the white paper, many hardware engineers today navigate an increasingly fragmented digital landscape. They jump between component-related PDFs, distributor portals, vendor websites, model libraries, and simulation tools — manually stitching context together as they go. Each jump introduces friction, uncertainty, and the possibility of data misinterpretation. Engineers are not simply looking for information anymore; they’re searching for confidence.

At the same time:

- Component datasheet specs alone no longer provide meaningful differentiation

- Design cycles are accelerating

- Supply chain volatility increases design risk

- A new generation of innovators and younger engineers expect consumer-grade digital experiences

A static datasheet just can’t satisfy that new reality.

Design enablement: A new mandate for component manufacturers

The white paper discusses design enablement as a modern solution — one that transforms component manufacturers from passive content providers into active design partners. Design enablement means offering interactive, simulation-ready, context-rich design assets directly within the manufacturer’s digital environment. Rather than engineers seemingly forced to assemble insights from scattered sources, the component manufacturer becomes an extension of the engineer’s workflow.

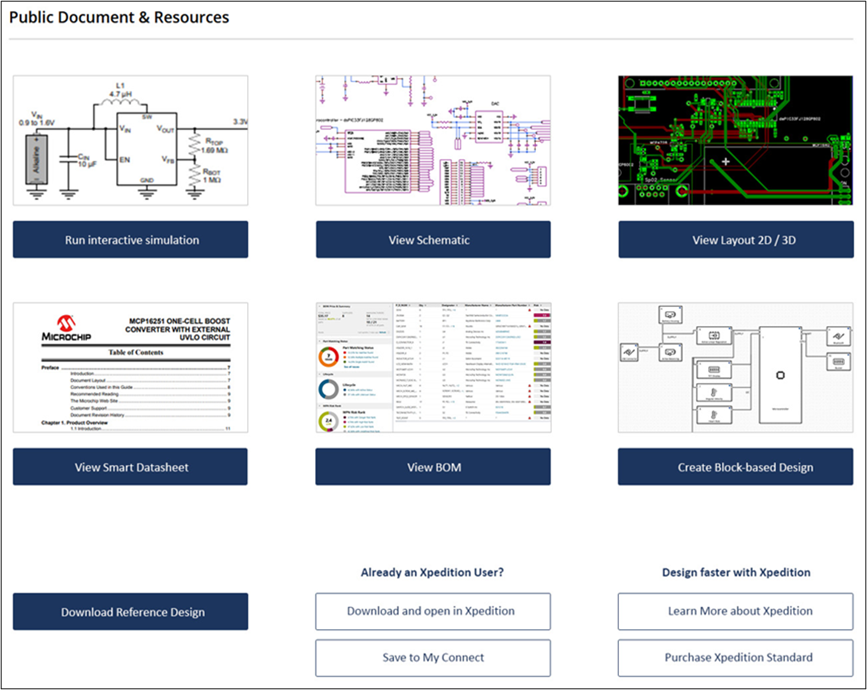

This encompasses capabilities such as in-browser interactive simulation of application circuits, “smart” documentation, ECAD-ready models, validated reference designs, supply-chain-aware BOM review, early DFM insight, and secure collaboration workflows. Together, these tools reduce uncertainty, accelerate design decisions, and keep engineers anchored within the component manufacturer’s ecosystem at the exact moment design-in decisions are made.

A real-world design journey: From clicks to confidence

The white paper shares a powerful example — the journey of Jennifer, a hardware engineer designing a battery-powered memory game prototype. Instead of downloading PDFs and guessing her way through component evaluation, Jennifer interacts directly with:

- A virtual application circuit

- Parametric simulations matched to her exact requirements

- Validated reference designs

- Layout previews

- Early supply chain signals

- Seamless transition to ECAD environment

All without leaving the manufacturer’s domain. The experience gives Jennifer the confidence to move forward with the hero component — not because she read the datasheet, but because she saw it work in her specific use case.

This is what design enablement looks like in action.

Why it matters: A shift from components to workflows

Design enablement matters because it fundamentally reshapes how engineers form trust and make decisions. It moves component manufacturers upstream, into the earliest phase of problem exploration — long before a part number is chosen. Instead of relying on datasheets to speak for themselves, component manufacturers gain visibility into what engineers are actually testing, simulating, and modifying. These engagement signals reveal real design intent that static documentation could never surface.

Design enablement also scales technical guidance far beyond what FAEs can deliver on their own. Small design teams, startups, and SMB innovators — typically underserved segments — gain access to high-quality design assistance without the need for live support. And by keeping engineers inside a secure, branded environment, component manufacturers avoid the “digital leakage” that occurs when design engineers from OEMs end up evaluating components through third-party aggregators. In markets where technical differentiation is narrowing, the quality of the design journey becomes a durable competitive moat.

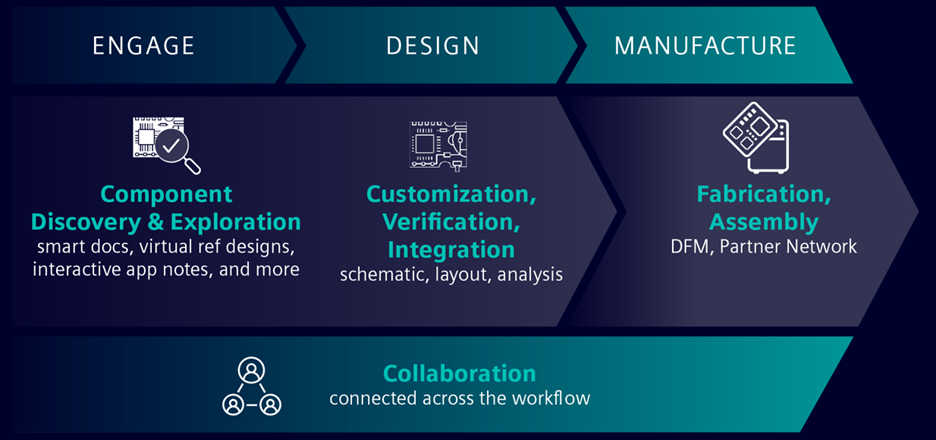

The future: Discovery → Design → Manufacturing in one continuous flow

As argued in the white paper, the future of component engagement lies in connecting the complete engineering lifecycle. The next generation of digital platforms will guide engineers from early exploration to simulation, from risk-aware component selection to secure ECAD handoff, and all the way through manufacturing readiness and lifecycle support. This creates an unbroken chain of digital continuity where every design decision, constraint, and validation follows the engineer forward.

When these stages are seamlessly connected, engineers move faster and with greater confidence — and component manufacturers evolve from being simple suppliers to becoming indispensable design partners. The value shifts from selling a component to enabling a complete, trusted workflow from first concept to production.

The design journey is the product — and the opportunity

Component specifications may be what first draw an engineer’s attention, but they are no longer what earn the design-win. Today, it is the design experience — the clarity, confidence, and continuity an engineer feels from first click through final validation — that determines which components move from consideration to commitment. A well-designed digital journey reduces friction, accelerates decision-making, and eliminates uncertainty at precisely the moments that matter most.

Component manufacturers who embrace design enablement are doing more than improving user experience. They are creating a strategic advantage: deepening engagement, strengthening brand trust, and becoming integral to the engineer’s process. As design cycles get shorter and product requirements grow more complex, the companies that invest in these modern, interactive, workflow-driven experiences will ultimately shape how the next generation of electronic systems are conceived, validated, and brought to market.

Want the full analysis? Download the white paper

This blog only scratches the surface. For a deeper look at the trends, risks, and opportunities reshaping component engagement, read the full white paper:

Rethinking the design journey: Why design enablement is the future of component engagement.