Do it yourself – Design for Manufacturing

When it comes to creating a PCB, we’re all looking to optimize product quality, reduce cycle time, and lower cost. When we run into roadblocks prohibiting us from reaching these goals, we look to see if these problems are manufacturing or design related. Guessing between the two can cause major setbacks, but DFM (Design for Manufacturing) analysis can aid in pinpointing fabrication and assembly process issues and guide us to resolving them before boards are sent further in the PCB creation process. Studies have shown that it can cost a PCB manufacturer as much as 20% of the total cost of the PCB for fabrication engineering teams to prepare it for manufacturing themselves. So why not have layout designers find and fix issues earlier?

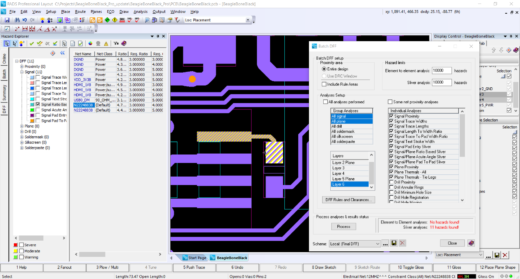

The PADS Professional integrated fabrication preparation environment helps you enhance the relationship between layout and manufacturing – giving designers the chance to address potential fabrication issues before getting designs in the hands of manufacturers. Designers can create unique documentation, produce manufacturing-ready outputs, and report fabrication analysis with PADS Professional’s DFM features and their tight integration with layout.

Interested in learning how these features can aid in your board creation?

Join our FREE webinar October 16, 2019:

Perfecting Your PCB with DFM Analysis

Register now!!