Don’t Let DC Drop Keep Your Products Off the Market

It might sound strange to compare movies and TVs to electronics design but, if you think about it, the path of the entertainment industry and the world of electronics are on similar trajectories. Movie and television viewers have high expectations that content should have flawless special effects, captivating story lines, and compelling musical scores…all at the same time.

How does that apply to the world of electronics? Well, as consumers, we also demand that our electronics work flawlessly. We expect them to be reliable, last longer, and work on-the-go. Some of the original cell phones (ahem, some of us are old enough to remember them!) could barely make it a day on a single charge, and all they did was make phone calls.

Today, smart watches have more brains than our old cell phones, wearables keep us informed about our health in real time, and smartphones track our schedules, e-mails, and text messages, take family photos, and stream music. Like modern entertainment productions, the bar for product creation has been forever raised.

What if I told you that a big secret to the longevity and performance of these electronics is in the power delivery network? It may not have been on the tip of your brain, but it’s crucial to have a reliable power delivery network that doesn’t lose too much voltage in the traces and wires that go between power supplies and the hungry chips they feed.

Modern ICs and digital and analog signals run off many power supplies and often have high current demands. So, if you can’t keep your power supplies within tolerance, the product you’re designing won’t last long in the real world.

What approach does your team take to guarantee that your PDN sees minimal voltage loss? If you told me you just make a prototype and go from there, I’d tell you that, like modern special effects, there is a better way.

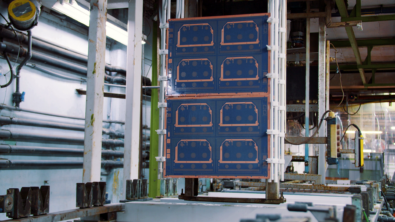

PADS HyperLynx DC Drop, part of the PADS Product Creation Platform, can actually help you figure out where and how much voltage loss you’re experiencing before a single board is built. The simulation software takes in your PCB layout from PADS, helps you assess power supply sources and sinks, and intuitively shows you voltage loss or current crowding for one, or all, of your power nets.

With knowledge of where, and how much, voltage loss is occurring, you can go back to layout, add more copper, and move to the next stage of your product design with peace of mind. Staying competitive in this industry, whether you’re a budding engineer or a seasoned veteran, means you need to adopt the best design practices.

Don’t let DC drop woes keep your product off the market! Attack it with PADS HyperLynx DC Drop, now part of the PADS Product Creation Platform.

– JM

Comments

Leave a Reply

You must be logged in to post a comment.

Good article. Thank you!