Wiring harness development in today’s automotive world

The never-ending development of new technologies and their addition to modern vehicles leads to a phenomenon that can be labeled as the Content Dilemma. The Content Dilemma represents the conflict between the technology content that vehicle manufacturers try to integrate into their vehicles, and the weight, cost and packaging space required for wiring harnesses.

Examples of recent technology trends that are driving the Content Dilemma include (figure 1):

- Electrification

- Autonomous Driving

- Artificial Intelligence

- Connected Vehicle

A key competitive factor for customers in an electric vehicle is range. The more miles a vehicle can drive with one charge, the better. Vehicle mass plays a key role in determining a vehicle’s range, therefore, minimizing weight in an electric vehicle is crucial to bringing a competitive and successful vehicle to market. New vehicle technologies, however, require additional electrical wiring and other electronic components, increasing the weight of the vehicle. The introduction of the electric powertrain alone adds about 30% more weight compared to an internal combustion engine powertrain.

Autonomous driving requires the addition of a multitude of hardware redundancies and fail safe mechanisms to prevent single points of failure that could disable the autonomous system unexpectedly. System redundancies are critical because unexpected failures may cause the vehicle to crash if the driver isn’t paying attention or actively involved in the driving and steering process. However, these safety redundancies can add significant weight and cost to the wiring harness by duplicating networks, powerlines, and some electronic control units (ECUs).

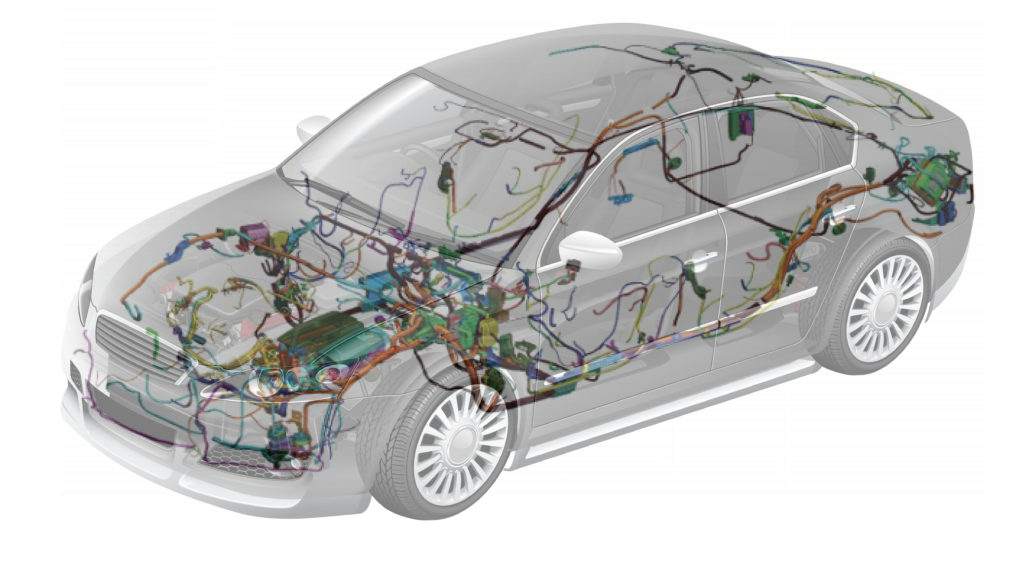

Vehicles are also becoming highly connected as part of the internet of things and internet of vehicles, transforming the vehicle into a seamless interface between our connected lives at home and at work. The integration of screens and displays into almost any imaginable interior surface demonstrates the vehicle’s growing role as a hub for entertainment, communications, and productivity. All this technology has to be connected together, driving OEMs to incorporate more networks, such as CAN, and leading to wiring harnesses that are heavier, larger, costlier, and more complex (figure 2). Some modern vehicles contain close to 40 different harnesses, comprised of roughly 700 connectors and over 3000 wires. If taken apart and put into a continuous line, these wires would exceed a length of 2.5mi (4km) and weigh approximately 132lbs (60kg). In addition, OEMs will need to integrate high baud rate networks with specialty cabling to support the increased features and functionality of new vehicles. Modern vehicles can contain more than 70 specialty cables, such as coax, high speed data, and USB cables. In older cars, this number was closer to 10.

How can today’s automotive manufacturers solve the Content Dilemma? Via the introduction of methods that help development teams to reduce the impact of added content and technology on the weight, cost, complexity, and packaging space required for wiring harnesses.

One solution is to develop technologies that reduce harness weight. Ultra -small diameter wiring (0.13mm2) is one good example. Unfortunately, the industry is still struggling to develop a sufficient number of terminal substitutions for all currently existing terminals that can crimp to such a small wiring diameter. Reducing the wire size on common circuit types, such as CAN busses, can achieve quick weight savings without necessitating a complex subset of connectors and pins, but the available products on the market currently do not support a large-scale migration to ultra-small diameter wiring.

Finding alternatives to specialty cables will further reduce the weight, cost and bundle diameters of harnesses. The number of cameras and displays will only increase in the future. OEMs must balance between using high baud rate networks that require specialty cabling and installing a greater quantity of lower baud rate networks, based on the resulting cost, weight, complexity, and risk of the harness. In the near term, widely used standards, such as CAN FD, that provide higher baud rates while operating on inexpensive twisted pair wiring may provide an easier and lower risk upgrade path. Alternatively, finding ways to multiplex these signals onto one shared specialty cable and having multiple devices tap into these cables will have the same effect: reducing harness weight, cost and bundle diameter.

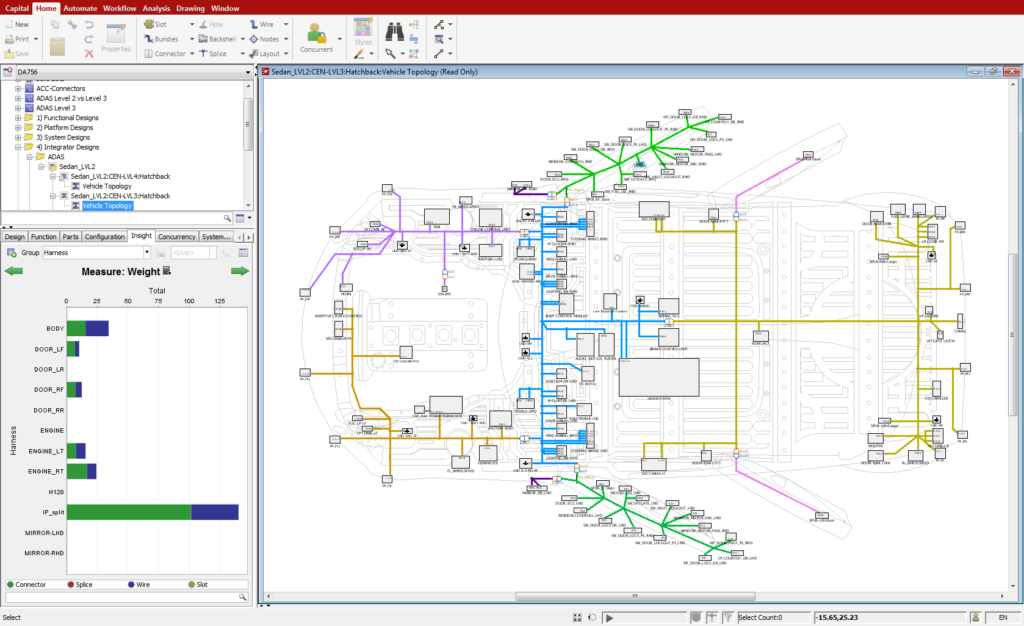

Another approach is using advanced software solutions, such as Capital, part of the Xcelerator portfolio, that support tradeoff studies to optimize module locations and identify any modules that can be combined to save weight, cost, and reduce bundle sizes (figure 3). The ability to compare and analyze layouts for their impact on harness weight, cost and bundle diameter will enable engineers to choose the most optimal system architecture.

To learn more, read our whitepaper: Automotive trends create new challenges for wiring harness development