New industry white paper: Six ways to reduce electrical program risk during platform development and integration

The increased demand for profitability, along with emerging trends such as implementing more capabilities using electrical systems, has made platform development of A&D systems a high-risk endeavor.

With complexity and systems integration issues on the rise, companies face competitive pressures not only at the platform level but throughout the entire supply chain. Design requirements now spill over into multiple disciplines impacting the product hierarchy across all facets of design, development and manufacture.

How do we overcome these challenges?

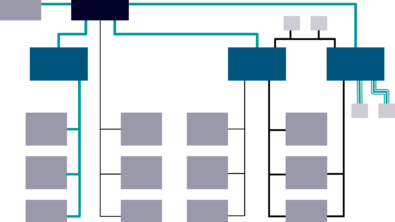

The good news is we are in the early stages of an industry-wide digital transformation. Adopting a digital strategy empowers companies large and small to take on today’s challenges and complexities – in addition to helping streamline operations. And Siemens has been at the forefront with our comprehensive digital twin and digital thread technologies for the A&D industry. Once deployed, these technologies allow customers unprecedented levels of visibility, oversight and collaboration across disciplines.

New white paper addresses ways to reduce program risk and stay profitable

Here’s an opportunity to read about Capital’s model-based approach and the role it plays in the aerospace industry today. I urge you to read our white paper “Six ways Capital reduces program risk during A&D platform development and integration.” The paper describes the new Capital E/E Systems development environment from Siemens, tackles program risk throughout the electrical platform lifecycle, from inception to system design and finally to manufacturing.

Topics include:

- How to optimize an electrical system’s architecture before even starting the design.

- Automatically applying institutional knowledge and experience.

- Collaborating across design disciplines.

- Generating compliance evidence as the electrical system evolves.

- Linking manufacture engineering to harness design.

- Accelerating routine maintenance and maximizing operation availability.

This paper gives you a detailed account of how to reduce risk, foster new innovation and reach your program goals.

Early customer successes

Already aerospace companies are making the transition to a more digitalized work environment with Capital Forward-thinking companies such as Pilatus, KAI, Bell and Boeing have shared publicly, how their adoption of Capital to design and manufacture their electrical systems has added significant value to their product development processes.

When you’re done reading the white paper, make sure to visit our Capital Aerospace & Defense website.

I hope you’ll take the time to read the white paper. There are just so many meaningful and exciting ways to embrace innovation and digitalization these days.