Improving electrical system and wiring design

Electrical systems are more complicated than ever. Today, the electrical and electronic complexity of even the “simplest” machines has ballooned, creating significant challenges in design and manufacturing. Today’s electrical engineers need more than basic electrical drawing software; they need tools that take the complexity out of the task, helping them work smarter and faster.

VeSys is used by hundreds of original equipment manufacturers (OEM) and wiring harness manufacturing companies worldwide. These include small firms with 10 employees, up to the largest and most well-known companies in the industry. VeSys provides automation facilities that eliminate many of the most labor-intensive and error-prone tasks, and robust data continuity to improve collaboration. Companies that adopt the tool typically experience payback in less than 9 months through reduced design-cycle times, reduced rework costs and improved margins as a result of its advanced capabilities.

In a new whitepaper, we describe twelve ways that VeSys can improve the design of electrical systems and wiring and harness designs for complex systems. Keep reading for a preview of what you can learn in the whitepaper.

Wiring Design

Advanced analysis and verification – test before you build

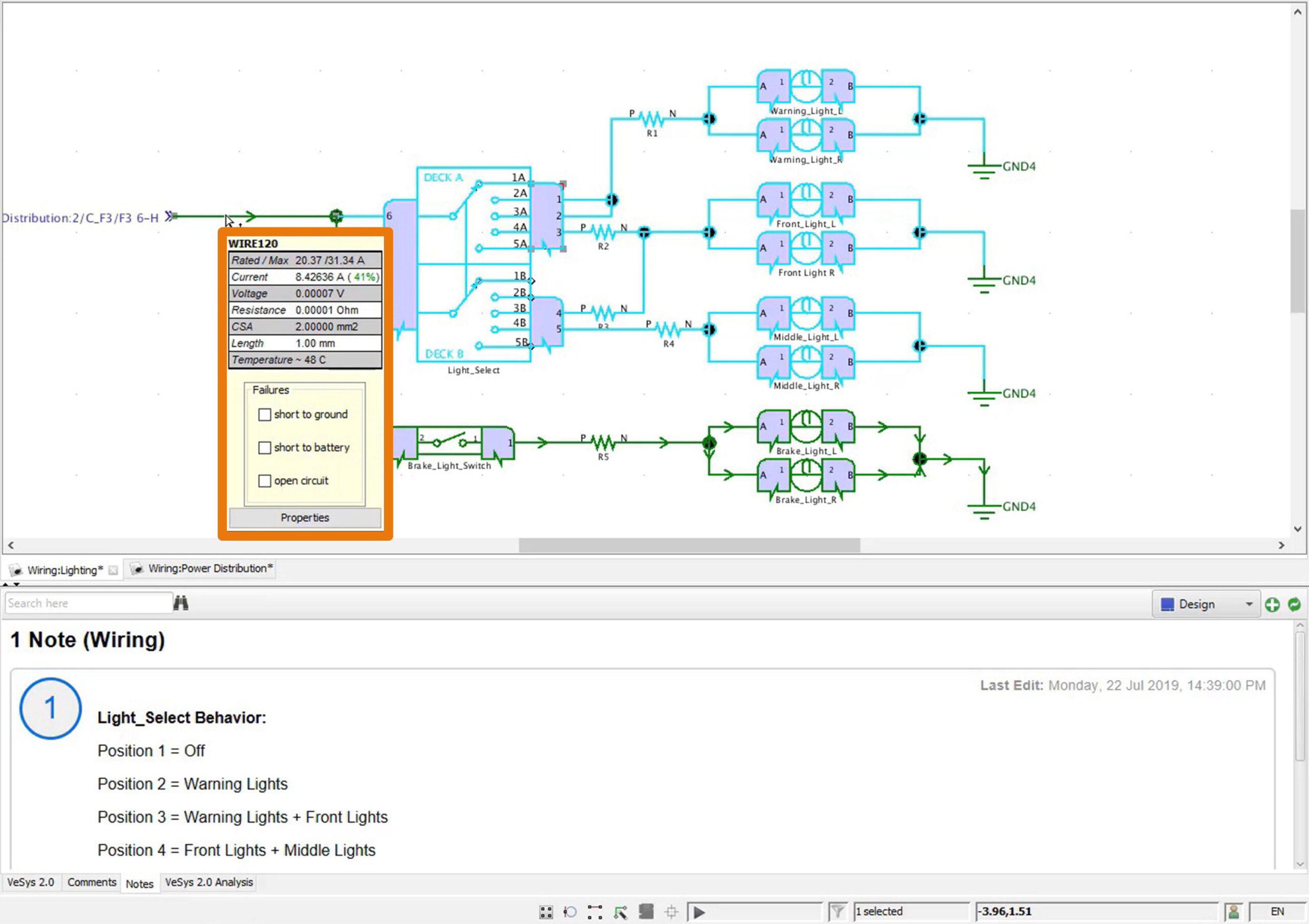

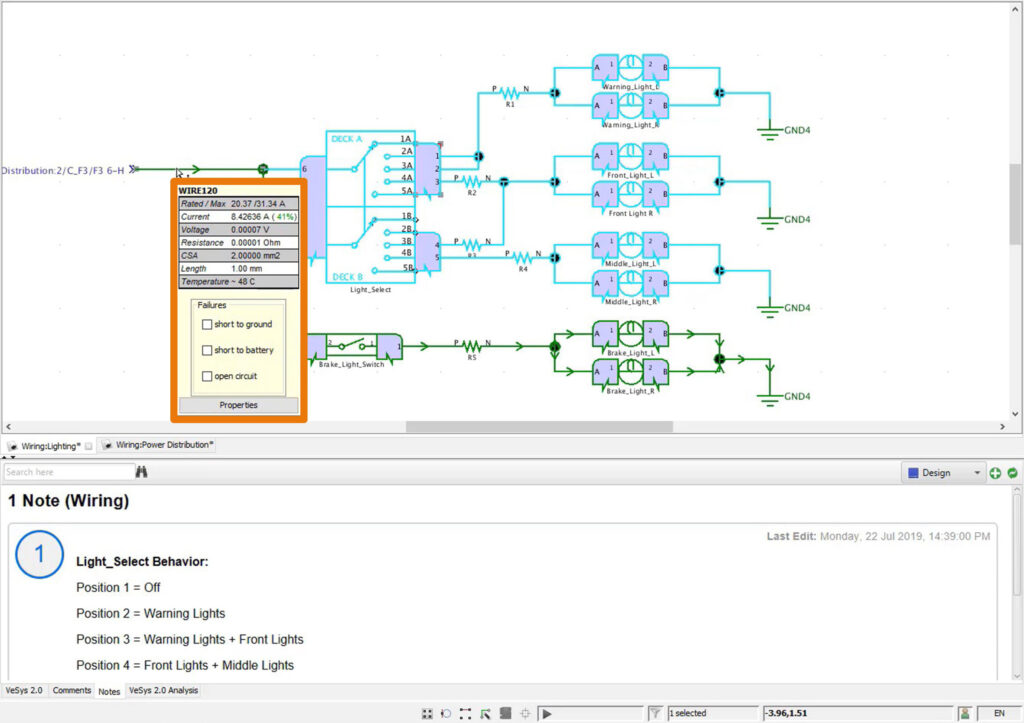

First prototypes often encounter issues and glitches that disrupt functionality. Virtual testing can identify these problems before a physical prototype is produced, saving time and money. Components in VeSys, such as wires, switches and fuses, are intelligent objects that can interact and respond to simulated conditions. This provides a virtual verification and test environment for checking wire and fuse ratings, and correct circuit behavior (figure 1). VeSys also provides functionality to assess and rank the impact of failing components on systems, detect unintended or failing system activity, and validate operation under stress. This can save valuable prototype testing time and eliminate costly errors.

Figure 1: Objects in VeSys are intelligent and can respond to simulated conditions, allowing for early verification of designs.

Import wire lengths – analysis enhanced by MCAD integration

Legacy tools require engineers to manually enter and calculate wire lengths, even though the data already exists in the mechanical domain. VeSys integrates with industry leading MCAD solutions such as NX to enable the import of wire lengths from a 3D harness into your wiring design. This allows for additional analysis to be performed such as voltage drop calculations. In addition, connectivity and wire diameter information can be passed back to the 3D harness to conduct interference studies within the MCAD tool. This also helps reduce errors and enhances collaboration across design domains.

Harness Design

Wire import from spreadsheet – faster quotation turnaround and design creation

Wiring harness manufacturing companies receive wiring designs and data in a variety of formats from customers to use in building quotations and creating wiring harness designs. For harness manufacturers, the speed with which they can turn around quotations can mean the difference between securing and losing potential customers. Once a customer is secured, the quality and accuracy of the harness designs produced become critical to ensuring repeat business. VeSys can import wiring information from an array of formats including AutoCAD Electrical, spreadsheets and existing VeSys wiring data. The direct importation of this information, coupled with advanced automation capabilities, can reduce quotation time to less than 1 hour. Engineers at the harness manufacturer need only to create the “stick” layout, import the wiring data, add protections, fixings and connectors. VeSys can then automatically generate the cost report.

Instant generation of BOMs, NC & Tester files, and manufacturing reports provides better manufacturing process documentation

The harness designers must produce a wide range of documentation to support downstream processes such as manufacturing and service. The volume and detail of the required documentation means that it can take a long time to produce; so long that it frequently becomes a bottleneck in the harness lifecycle. VeSys can accelerate the creation of this documentation with pre-formatted and customizable templates that the tool can fill in automatically. Users can generate bills-of-materials (BoM), manufacturing reports and more instantly from harness diagram. A task that typically takes one or two days can now be achieved in a few seconds. This becomes even more valuable when design changes are made. VeSys can generate new documentation in seconds directly from the updated wiring and harness designs. For every VeSys user, this capability alone is sufficient to generate a rapid ROI.

These are just a few of the ways that VeSys can help improve the design of electrical wiring and harnesses for today’s increasingly complex systems. You can learn more by downloading our whitepaper Improve wiring and harness design with twelve advanced capabilities.

You may also be interested in: