Mitigating electrical system compliance risk in today’s aircraft

For those developing and mitigating electrical system compliance in today’s aircraft, there are two major trends shaping our industry.

First, increasing mission demands are escalating platform performance requirements. Whether it’s further extending the range of a twin-engine aircraft, increasing battery hold-up on a large commercial aircraft, or enhancing jet fighter effectiveness – there is an intense demand for more mission capabilities.

Second, are the trends relating to new levels of complexity due to increased electrification. More than ever, platform developers are implementing new functionality via electrical solutions. Many of these electrical approaches are replacing mechanical, pneumatic, and hydraulic implementations of existing functionality – becoming commonplace on today’s aircraft.

Which is a very good thing!

The rise of EWIS

But here’s the deal. As a direct result of the increased use of electrical solutions, we are now seeing the increased size, weight and complexity of the Electrical Wiring Interconnect System (EWIS). EWIS complexity is further compounded by a myriad of rules to minimize electrical interference, signal separation for redundant systems, and of course, to ensure compliance and/or commercial certification.

Much of the work done to address this new level of complexity are on spreadsheet-based tools where the data is manually transferred. These tools are often stand-alone tools so the sharing of critical data becomes a major obstacle. Unfortunately, many of the current methods used today were developed in an era when aircraft electrical systems were far less complicated.

There has to be a better, smarter way to do this.

How to address EWIS and the need for more electrification – while taking on electrical system compliance risk

The good news is Siemens has developed a new compliance tool to help users responsible for conducting Electrical Load Analysis (ELA) during this time of increased complexity. This new compliance tool, Capital Load Analyzer, is one of the industry’s first electrical systems technologies to leverage automation and digital data continuity to facilitate faster regulatory compliance.

To learn more about this breakthrough approach on electrical system compliance, please read the white paper, “How to mitigate electrical compliance risk in aerospace: a new approach.”

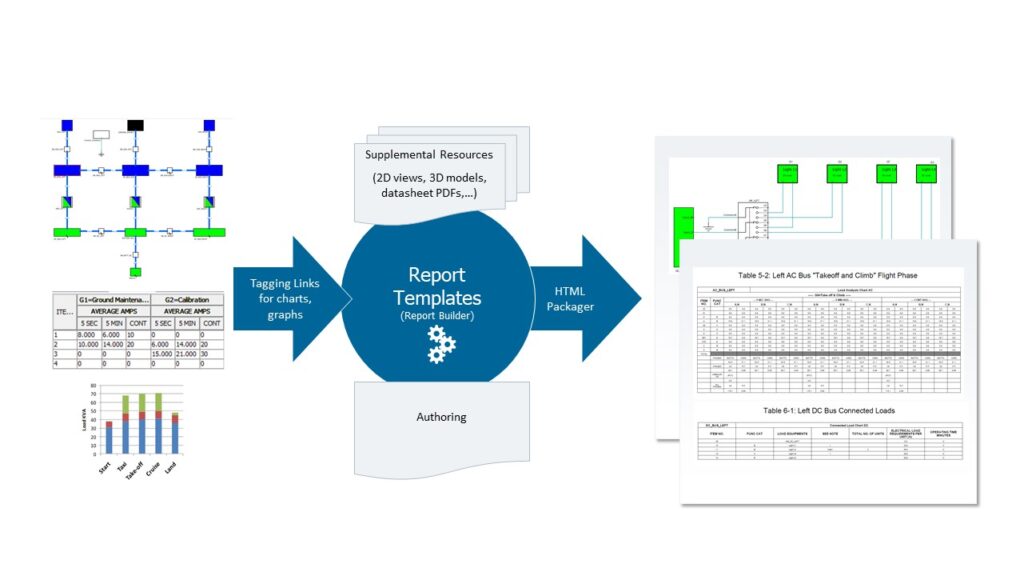

Capital Load Analyzer automatically extracts all electrical load analysis data into your own reporting template for easy and efficient report generation. This technology pulls data directly from the digital twin so you can see the impact of design changes at any time and at any stage of the design process.

Final words

I hope you’ll take the time to read about this promising new technology. Capital has always been at the forefront of modern, comprehensive solutions and this new approach continues our streak of productive and breakthrough tools.

So, if you want to… complete ELA earlier in your program… reduce program risk… experience fewer findings during peer reviews… achieve higher first-time quality… quickly validate early electrical system designs… and avoid late program design iterations…

Well, then, Capital Load Analyzer is the tool for you.

Learn more by reading the white paper now.

You may also be interested in: