Electric vs. combustion: A comparison of student racers

Due to declining urban air quality, climate change and consequent legislative changes, demand for environmentally-friendly mobility is increasing. Accordingly, vehicle electrification has become a very important field of study, especially in the last few years. The internal combustion engine (ICE), around for over a century, is obviously a well understood, mature technology. While there is room for further innovation, improvements will be largely incremental and heavily constrained by cost.

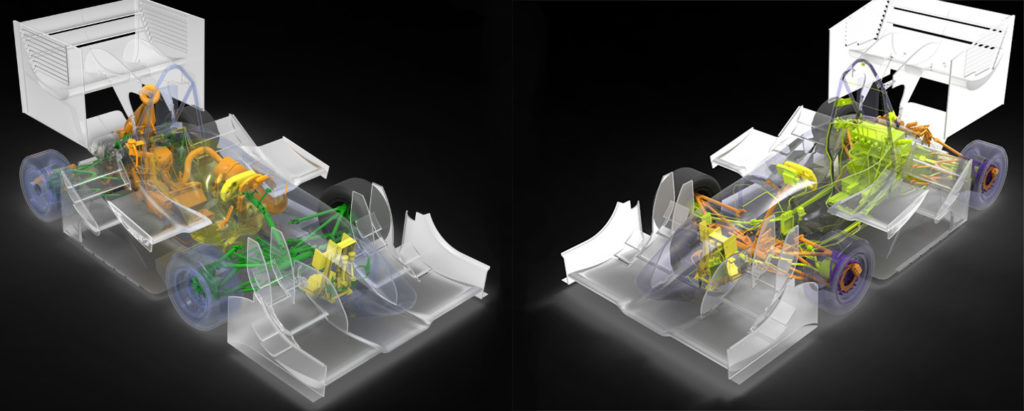

In contrast, electric vehicles yield the potential for completely new concepts and innovative solutions. The electrical system plays a key role in the process of electrification, involving some risks but also considerable potential. TUfast Racing Team – the Formula Student Team of the Technical University of Munich – is one of only a few student teams worldwide to build both an internal combustion engine (ICE) and a fully electric race car every year, thus allowing a comparison of electric and ICE cars first-hand.

The team produced a paper that analyzes the key differences, main challenges and potential of electrical systems for Formula Student Electric (FSE) in comparison to Formula Student Combustion (FSC) cars, using the example of the TUfast Racing Team cars. Furthermore, CAE development tools from Siemens, are presented which help significantly in the design and development of efficient electrical systems in the vehicles. Finally, the paper explores the potential of knowledge transfer from Formula Student to commercial EVs.

In brief, the paper describes that there are fundamentally different challenges in developing electrical systems for FSC and FSE race cars. On the one hand, mechanical stress, caused by vibration, heat and chemical corrosion is a large factor for FSC cars. On the other hand, EMC, computational power and safety are essential considerations for FSE cars. The problems FSE cars face will also be a challenge for commercial electric vehicles. Besides potential EMC considerations, due to the HV system of the electric powertrain, EVs provide the opportunity for innovations in the electrical system, specifically the high voltage wire harness, control unit, battery pack and safety.

The different approaches in these fields in the Formula Student competition show that there are no uniform solutions. What is true is that powerful development tools are needed to find new, innovative and economic solutions. Additionally, FSE is a showcase for new capabilities in precise vehicle control, due to the excellent controllability of electric motors as well as the possibility of multiple motors. In FSE race cars, these vehicle control capabilities are used to improve lap times (e.g. by torque vectoring). For commercially available vehicles, especially for sports cars, vehicle control can also be used to improve driving enjoyment.

Formula Student demonstrates that, when it comes to electrification, it’s not only necessary to make small adaptations of the electric system for the new powertrain, but in fact what’s required is a complete reinvention of the whole system, its subsystems and architecture. Developing system architectures that satisfy safety and reliability will also be essential for future autonomous vehicles.

You can continue reading in the whitepaper: Internal combustion vs. electric powertrains: a comparison of electrical system design in formula student vehicles.