When sea freight gets smarter: How AI is turning supply chain chaos into competitive advantage

Your container is stuck somewhere in the Red Sea. Again. Your customer is furious. Your margins are bleeding. Sound familiar?

If you were managing supply chains and sea freight in 2024 (or ever since), you’ve lived this nightmare. Transit times have exploded by 20-30% across major trade routes The Red Sea crisis has ships playing maritime pinball around the Cape of Good Hope. Port congestion is the new normal, with vessels waiting days instead of hours for berth space.

But here’s what’s separating the supply chain leaders from traditional players: They’re not just reacting to disruption—they’re predicting it.

The $6 billion problem no one saw coming

The numbers reveal a harsh reality. The Red Sea crisis alone disrupted $6 billion in weekly trade flows. Container shipping costs from China to Brazil jumped 249% in a single year. With approximately 550 vessels arriving in US ports weekly, the ripple effects of every delay compound exponentially.

Traditional tracking systems are like trying to navigate a hurricane with a paper map. By the time you know there’s a problem, it’s already cost you weeks of delays, thousands in demurrage fees, and potentially a major customer relationship.

The industry desperately needed a crystal ball. Instead, it got something better: Artificial Intelligence that actually works.

Meet the AI revolution that’s already happening

This isn’t another “AI will change everything” story. This is about AI that’s already changing everything for forward-thinking supply chain leaders.

Siemens Digital Logistics and Portcast have cracked the code on predictive ocean visibility. While traditional tracking sticks to the basics, this solution delivers supply chain intelligence that’s like having a maritime operations center from 2030 — way ahead of its time.

The secret sauce: 200+ data sources, one intelligent platform

Here’s what makes this different from every other “smart logistics” solution you’ve evaluated: 200+ sources of data stitched together with data science.

Portcast doesn’t just track containers—it predicts disruptions by combining:

- Satellite and vessel meta-data for real-time positioning

- Marine weather patterns and adverse climate tracking

- Port performance analytics and congestion indicators

- Economic indices and bunker fuel impact analysis

- Carrier data including blank sailings and route changes

The result? AI that doesn’t just tell you where your cargo is—it tells you where it’s going to be, when problems will hit, and what you can do about it.

Beyond visibility: Self-explaining intelligence for smarter decisions

Most AI solutions are black boxes. You get an alert, but you don’t know why. Portcast’s AI-based ETA predictions tell you not just what’s happening, but why it’s happening.

When the system predicts a 3-day delay at Le Havre, it doesn’t just flash a warning. It explains that Terminal De France GMP is experiencing 85-90% yard utilization while Terminal de l’Atlantique remains clear. This granular intelligence lets you make informed decisions instead of blind guesses.

“No one wants to look at a dot on a map. What we really care about are exceptions—and understanding the impact of those exceptions at a granular, shipment level.”

Nidhi Gupta, Portcast founder and CEO

The AI-powered control tower that never sleeps

Traditional supply chain visibility gives you data. Siemens’ AI-powered control tower gives you actionable insights.

The platform operates on three revolutionary principles:

- Predictive Intelligence: Machine learning algorithms analyze voyage changes, adverse weather, port congestion, and economic impacts to forecast disruptions before they cascade through your supply chain.

- Management by Exception: Instead of monitoring thousands of shipments, the solution automatically identifies which containers need your attention and why.

- Continuous improvement: The system learns from every disruption, incorporating that intelligence into future routing and scheduling decisions.

This isn’t just about better tracking—it’s about building anti-fragile supply chains that get stronger under stress.

The numbers that make CFOs pay attention

Let’s talk quantified results that matter to your executive team:

Operational efficiency revolution:

- 80% reduction in manual updates and missing data – Your logistics team stops chasing information and starts making strategic decisions

- 15% decrease in detention and demurrage charges – AI prevents the expensive surprises that kill quarterly profits

- 5% reduction in expedited freight costs – Better visibility means fewer emergency shipments

But the strategic advantages go beyond immediate cost savings:

- Customer confidence when you proactively communicate delays instead of explaining them after the fact

- Inventory optimization based on predictive ETAs rather than hopeful planning

- Competitive differentiation when your supply chain reliability becomes a market advantage

Sea freight integration that actually works in the real world

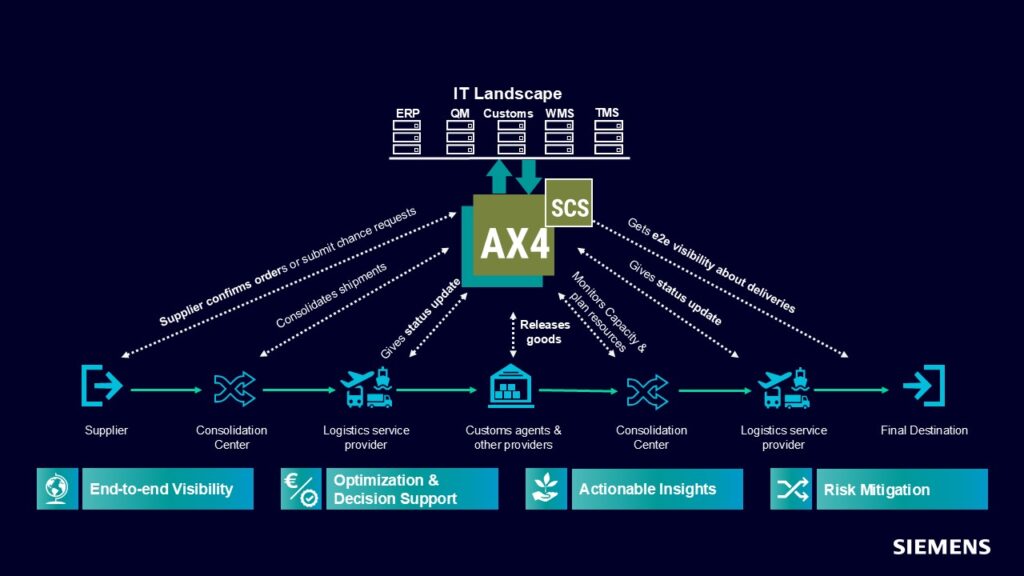

The dirty secret of most AI solutions? They don’t integrate with your existing workflows. That’s where Siemens’ AX4 platform changes everything.

This intelligence doesn’t live in another dashboard your team has to remember to check. Portcast’s APIs are fully integrated into AX4, creating a unified experience within your existing IT landscape.

Your planners see predictive insights alongside normal operations data. Exception alerts flow through established communication channels. The AI becomes part of your team’s daily decision-making process instead of another system competing for attention.

Over 500,000 users already have access to this best-in-class intelligence, seamlessly integrated into their existing workflows.

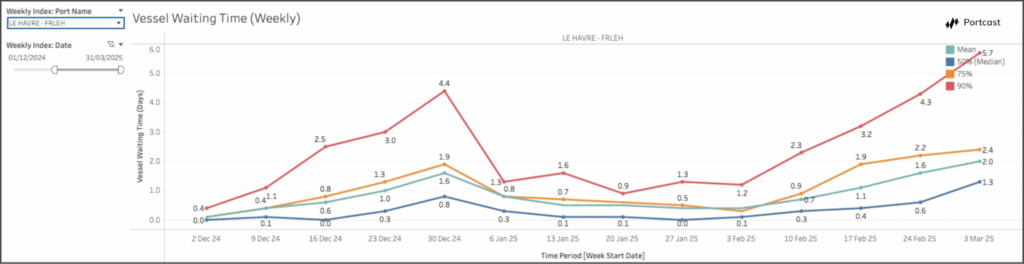

Real-world intelligence: The Le Havre example

Consider this actual scenario: Le Havre port reported congestion, but the AI revealed the complete picture:

- Terminal De France GMP: 85-90% yard utilization, vessels waiting 3-6 days

- Terminal de l’Atlantique: Minimal disruptions, vessels berthing without delays

- Overall impact: Median congestion of just 1.1 days, with only 10% of vessels experiencing delays over 5.6 days

Traditional systems would report “Le Havre congestion.” The AI-powered solution tells you exactly which terminal to avoid and provides alternative berthing options with quantified wait times.

This granular intelligence transforms reactive crisis management into proactive supply chain optimization.

The competitive gap is opening fast

Maritime artificial intelligence isn’t a future technology—it’s a $4.3 billion market growing at 40.6% annually. Leading shipping companies are already implementing AI-driven solutions across their operations.

Every month you delay adoption, competitors gain operational intelligence you’re missing out on. Every disruption they predict and you react to widens the performance gap.

The question isn’t whether AI will transform ocean freight—it already is. The question is whether you’ll be leading that transformation or you might risk to be left behind.

Why tomorrow’s leaders are moving today

The most sophisticated supply chain organizations aren’t just using AI for better tracking. They’re building resilient operations that turn disruption into competitive advantage.

When the next major crisis hits—and it will—these organizations won’t just survive. They’ll gain market share while competitors scramble to understand what went wrong.

The competitive advantage is clear: While your competitors explain delays to customers, you’re proactively communicating revised schedules and offering alternative solutions.

That’s the difference between operational excellence and operational desperation.

Ready to turn supply chain chaos into competitive advantage?

The Siemens Digital Logistics and Portcast partnership offers seamlessly inegrated solution powered by AI insightss that leading global companies are already using to transform their ocean freight operations. With quantified benefits including 80% reduction in manual updates, 15% decrease in detention charges, and 5% reduction in expedited freight costs, the platform delivers immediate improvements while building long-term supply chain resilience.

Don’t let another quarter pass watching competitors gain AI-powered advantages while you’re stuck with reactive logistics.

Contact Siemens Digital Logistics today to discover how explainable AI and predictive ocean visibility can transform your supply chain performance.

Transform disruption into opportunity. Transform chaos into competitive advantage. Transform your supply chain with AI that actually works

More information

- Read our fact sheet “AX4 real-time transportation visibility for sea freight”

- Learn more about our partner portcast: How Portcast and Siemens Digital Logistics create resilient, transparent supply chains

- Portcast website: https://www.portcast.io/

- Be part of our upcoming Webinar: