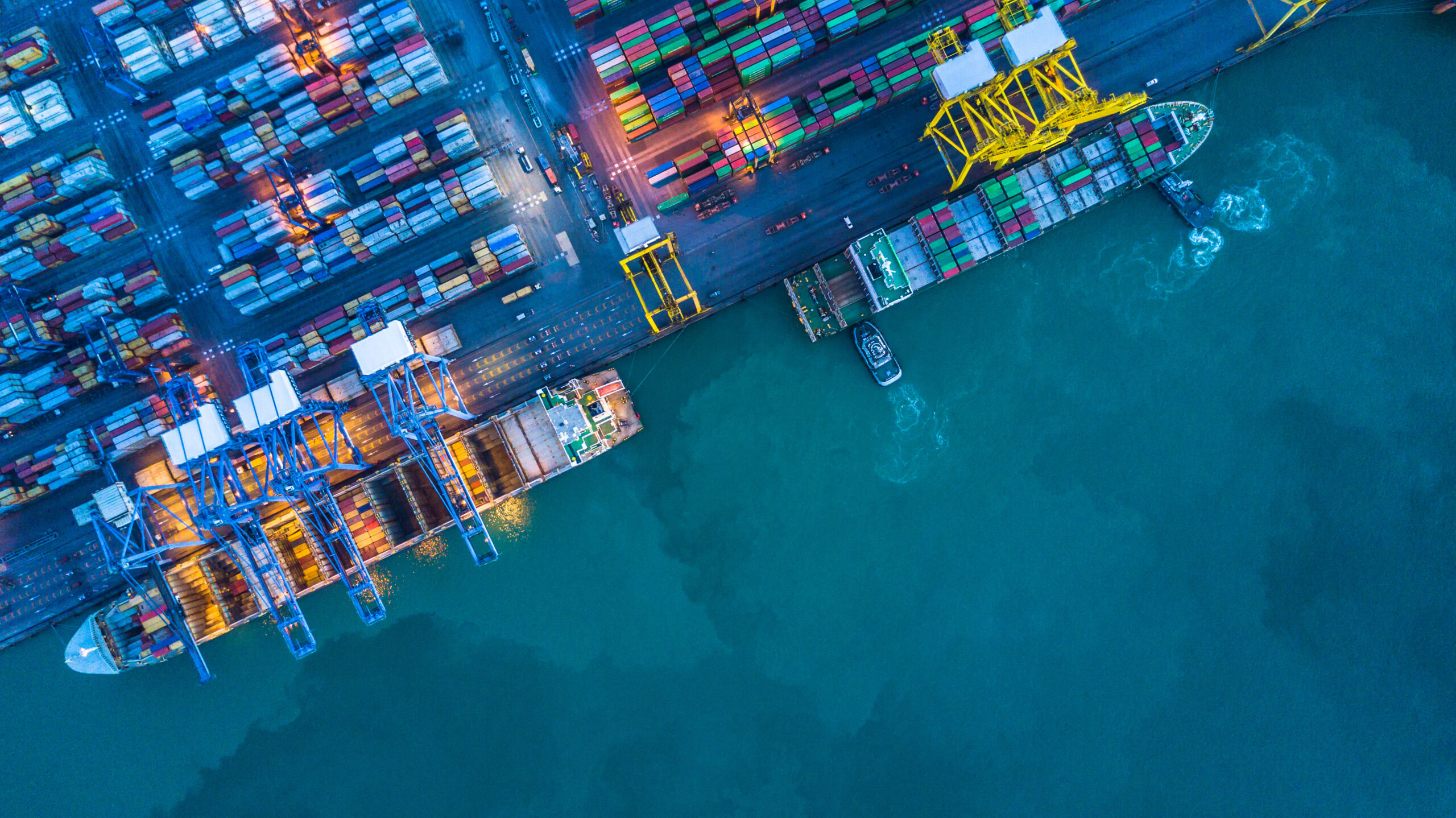

Building resilient CP&R supply chains: Lessons from recent disruptions

The wake-up call

Prior to March 2020, I’d suggest that the phrase “supply chain” was unfamiliar to most consumers. Since then, it seems whenever there is a delay of any type I will hear the phrase “supply chain disruption.” Everyone now knows that phrase, and they don’t just use it to describe shortages on the shelf or e-commerce delivery delays — I have read in the local newspaper that the reason a traffic signal has not been fixed is due to, you guessed it, “a supply chain disruption.”

The COVID-19 pandemic introduced many consumers to the basics of supply chains, and put organizations’ supply chain and logistics strategies to the test: Would their supply chains be flexible and adaptable enough to weather the storm? Would they emerge on the other side of the crisis stronger and ready for the next disaster? With 85% of consumer products and 88% of retail organizations reporting significant impacts from the pandemic, which took months to recover from, the event was a hard but necessary reality check for the CP&R industry.

After all, a pandemic may be a rarer type of disaster for CP&R companies to navigate, but it certainly isn’t the only one they’ll encounter. Natural disasters have and will continue to pose challenges for supply chain professionals. In the last handful of years alone, we’ve witnessed events such as the Suez Canal blockage and wildfires near critical rail lines drive up costs and extend delivery times for both manufacturer and consumer. Shifting weather patterns have brought both floods and droughts, impacting agricultural production, blocking roads, and restricting vessels passing through the Panama Canal.

How can CP&R companies safeguard their supply chain operations against future unpredictable disruptions? In this article, we’ll explore the unique challenges and pressures CP&R organizations face, and highlight key strategies to help fortify resilient supply chains.

Unique challenges of the CP&R industry

Transit delays are particularly harmful for CP&R companies which rely on both perishable ingredients and seasonal merchandise. When companies don’t receive orders on time, revenue and customer satisfaction suffer. It is estimated that in 2021, the blockage in the Suez Canal alone contributed to global trade losses of between $15 to $17 billion.

And revenue loss isn’t the only concern. Global trade disruptions come with environmental impact. From November 2023 to October 2024, approximately 1,200 cargo vessels from Asia chose to avoid the Suez Canal and transit around Africa. These marine companies collectively traveled 4.2 million nautical miles further, adding an additional 14,292 days to the journey and generating an additional $1.2 billion in fuel costs. Altogether, this change in route generated a whopping 11,028,660 metric tons of CO2 emissions. In an age when more and more consumers prioritize transparency and sustainability in their purchases, the repercussions of longer supply chain routes can damage consumer trust and loyalty in brands.

Finally, the CP&R industry is vulnerable to trade wars and tariff changes. In recent years, these geopolitical tensions have forced companies to re-evaluate their reliance on single-source suppliers, driving the need for greater supply chain diversification.

Strategies for building resilient supply chains

So, what can you do to help your business succeed amidst turbulence in global trade? While rapid changes in policy, demand, and global events can feel uncontrollable and unpredictable, there are actionable steps you can take to mitigate risk and fortify your CP&R supply chain against future disruptions. The following four strategies, when implemented together, can help you build a more resilient and adaptable supply chain.

1. Supply chain segmentation and risk profiling

Start by thoroughly assessing the vulnerabilities within your supply chain. Segment your operations based on factors like supplier importance, location, and exposure to disruptive events. This will enable you to prioritize mitigation efforts and allocate resources more effectively.

By mapping out your supply chain’s risk profile, you can identify potential bottlenecks and areas that require greater resiliency. With this visibility, you can develop contingency plans to address various disruption scenarios, whether they involve trade policy shifts, natural disasters, or public health crises.

2. Supplier diversification

Reducing your dependence on single sources of supply is crucial for building supply chain resilience. Diversify your supplier network to minimize the impact of disruptions to any one partner. Consider qualifying alternative vendors, regionalizing your sourcing, or exploring nearshoring strategies.

A diversified supplier base provides more flexibility to pivot your sourcing and distribution when new trade policies or tariffs emerge. You’ll be able to quickly reroute shipments, adjust inventory levels, and find new pathways to market while maintaining business continuity.

3. Real-time visibility and risk mitigation

Logistics management solutions from Siemens provide end-to-end transparency in inbound and outbound logistics, enabling you to gain real-time insights and improve decision-making. By connecting all your supply chain stages and processes, you can harness the power of data to analyze, simulate, track, and optimize your logistics networks.

Leverage the digital twin of your supply networks and logistics processes to implement a robust supply chain strategy. Simulate transport capacities to optimize and increase capacity utilization, manage inbound logistics disruptions, and adjust production orders accordingly. With our solutions, you can mitigate risk and achieve operational flexibility by synchronizing logistics and manufacturing.

4. Collaborative supply chain optimization

To navigate complex trade environments, it’s essential to integrate all stakeholders in a central collaboration system. Our logistics management solutions enable you to connect and coordinate with suppliers, carriers, and customers in real time.

By fostering collaboration and information sharing, you can quickly respond to disruptions, optimize inventory levels, and ensure smooth product flow. Siemens tools allow you to analyze, simulate, and optimize your entire logistics network, identifying opportunities for efficiency gains and cost savings.

Future-proof your logistics network

We find ourselves in the “new, never normal” period of global commerce. Looking ahead, it remains crucial to continually assess vulnerabilities and leverage flexible mitigation strategies to enhance and maintain the resilient supply chain.

The challenges we explored are reminders that building a resilient supply chain is no longer a nice-to-have, but a strategic imperative for CP&R industry leaders. By leveraging comprehensive logistics management solutions, you can secure your supply chain against future disruptions and gain a competitive advantage in the market.

To learn more about how Siemens can help you navigate the challenges ahead and future-proof your operations, check out our white paper, “A more intelligent supply chain: Merging industry and logistics in the digital realm.”

For a personalized consultation on how our logistics management solutions can address your specific needs, contact us today. We are happy to help.