Navigating the future of consumer products and retail: The intelligent supply chain revolution

Unlocking Efficiency, Innovation, and Consumer-Centric Solutions

In a consumer-centric world, where rapid technological advancements shape the very fabric of business, the consumer products and retail industry (CP&R) stands at the forefront of transformative change. It’s not just about streamlining operations for greater efficiency; it’s a journey into innovation and crafting solutions that place the consumer firmly at the heart of every endeavor. In this blog, we’ll dive into the evolution of the intelligent supply chain and its profound impact on the digital landscape within the consumer products and retail sector.

The new digital value chain

In the dynamic realm of CP&R, adaptation to the ever-changing market is essential. Consumer demands are steering the shift towards eco-friendly, diverse, and customized products. Today’s discerning consumers not only seek quality but also demand transparency, from understanding product origins to tracing the journey from raw materials to finished goods.

The cornerstone to success lies in trusted traceability, and data is the key. IoT technologies are empowering CP&R companies to provide visibility and intelligence throughout the production and supply chain, bolstering consumer confidence and enhancing brand loyalty by ensuring product safety throughout the entire lifecycle.

The role of the cloud is pivotal. Smart supply chain solutions with customizable components offer control over production and logistics. They enable seamless integration of stakeholders through a cloud-based platform, streamlining information exchange.

Additionally, the integration of machines via IoT takes CP&R to the next level, giving rise to the intelligent supply chain. This innovation leverages data across the entire value chain, facilitating precise logistics planning grounded in real-time production insights.

Say goodbye to guesswork as the intelligent supply chain predicts exact delivery times, unlocking automation possibilities and optimizing resources.

IoT: Fueling a logistics revolution

Imagine a world where every machine becomes a data source, from conveyor belts to gripper arms. This concept is the Internet of Things (IoT) in action. Sensors on these machines relay even the minutest details, preempting breakdowns and downtime.

In this smart world, entire factory floors are seamlessly interconnected. Connectivity not only aids production monitoring but also capitalizes on the vast potential of big data.

IoT is revolutionizing logistics. It empowers real-time adjustments, optimizing transport and reducing costs. The supply chain evolves into an intelligent entity, fostering effortless collaboration among stakeholders.

Additionally, IoT redefines customer satisfaction. Warehouse stock is no longer hoarded; it’s produced on demand. Same-day production and delivery are the new standards.

Predictive analytics simulate future scenarios, guiding decision-makers. When IoT is in action, it propels a logistics revolution.

The next leap: Precision and efficiency

The fusion of industry and logistics through IoT data is undoubtedly the next monumental step. To seamlessly integrate industry and logistics, a digital network is indispensable. It must facilitate communication between machines, humans, and systems, ideally residing in the cloud to foster collaboration across various devices and locations.

Pioneering industries have already embraced open, cloud-based IoT systems for internal processes. However, specialized IT components come into play to extend this interaction externally.

The intelligent, cloud-based supply chain epitomizes a data-driven network with adaptable components catering to the distinct needs of diverse industries. It guarantees end-to-end visibility across processes, with interfaces playing a pivotal role in facilitating seamless integration with an existing organization’s systems. This journey of integrating industry and logistics thrives on collaboration and innovation.

The digital marketplace: A hub of innovation

In today’s dynamic CP&R supply chain landscape, innovation isn’t a distant dream. Decision-makers now insist on on-demand solutions that adjust to their unique requirements. Established IoT platforms are the foundation for monitoring and integrating cutting-edge industrial machinery, giving birth to a digital marketplace brimming with services and solutions.

But what’s the secret sauce for a digital revolution? An open IoT system can accommodate various services, such as specialized logistics platforms and advanced analysis tools. This integration enables holistic value chain management, guaranteeing end-to-end supply chain visibility. Furthermore, data-driven analysis and AI unlock the full potential of logistics processes. AI detects patterns in data, calculates optimal supply chain trajectories, and pinpoints precise delivery dates. Enterprises harness these tools to enhance processes, provide superior customer service, and optimize resource utilization.

This intelligent fusion of production and logistics creates a new era of predictability and transparency throughout the entire process chain, redefining how CP&R companies operate in a rapidly evolving digital marketplace.

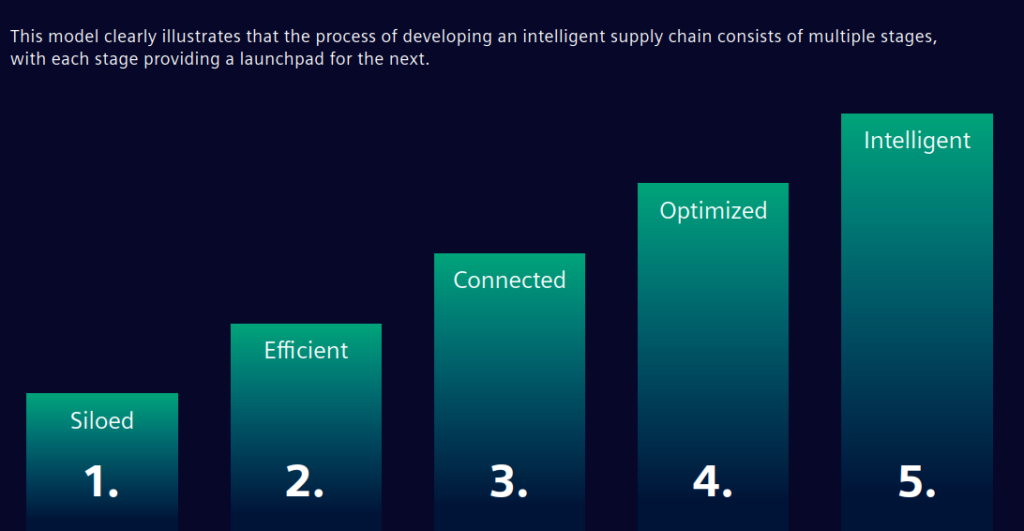

Five steps to an intelligent supply chain

Our roadmap towards an intelligent supply chain draws inspiration from Gartner’s 5-Stage Maturity Model. This journey commences with isolated processes and evolves into a seamlessly connected, highly efficient, and optimized system. Ultimately, it culminates in a state of intelligence achieved through IoT, analytics, and artificial intelligence (AI).

1) Siloed: Businesses frequently operate with siloed logistics and supply chain management processes in the initial stage. These processes exist in autonomous compartments, possibly within separate systems like an ERP (Enterprise Resource Planning) system. Information remains confined, hampering visibility and collaboration across the supply chain.

2) Efficient: As organizations advance to the Efficient stage, they begin dismantling these silos. Logistics processes become more efficient as the system’s functional reach expands. This process entails integrating various supply chain components, such as inventory management, transportation, and order processing, into a cohesive system. This integration fosters improved coordination and streamlines operations.

3) Connected: Businesses take a significant leap forward at the Connected stage. They integrate all supply chain partners via collaboration platforms, fostering digital communication and information-sharing within the network. Collaboration platforms facilitate real-time data exchange among suppliers, manufacturers, distributors, and customers. This connectivity paves the way for enhanced coordination, visibility, and responsiveness across the supply chain.

4) Optimized: Optimization marks a strategic shift in supply chain management. Beyond simply streamlining individual logistics processes, optimization becomes a strategic, iterative process. It’s driven by the deployment of appropriate IT tools that enable organizations to redesign their entire network and operational workflows. This stage emphasizes the continuous improvement of supply chain efficiency, cost-effectiveness, and performance.

5) Intelligent: The Intelligent stage represents the pinnacle of supply chain evolution. Organizations leverage advanced technologies, including IoT (Internet of Things) apps, analytics,and eventually AI (Artificial Intelligence). These technologies provide a superior decision-making basis and engineer solutions for complex logistics challenges. IoT sensors monitor assets in real time, analytics derive actionable insights from data, and AI enhances predictive capabilities. This level of intelligence allows businesses to proactively respond to supply chain disruptions, optimize routes, and precisely meet customer demands taking digital transformation to the next level and embracing the intelligent supply chain.

Taking digital transformation to the next level and embracing the intelligent supply chain

Picture a world where the CP&R seamlessly collaborates within a high-tech ecosystem, all orchestrated by the Internet of Things (IoT). In this digital realm, unparalleled efficiency, peak performance, and data-driven decision-making become the norm. It’s an environment that nurtures innovation, reshaping the competitive landscape of CP&R.

As we journey through the era of digital transformation, adaptability and innovation take center stage. The convergence of industry and logistics in the digital arena, propelled by technologies like the Internet of Things (IoT) and Artificial Intelligence (AI), isn’t just a fleeting trend—it signifies a profound transformation. The intelligent supply chain, empowered by these technologies, awaits those ready to seize its potential.

For the CP&R sector venturing into this digital frontier, the promise of heightened efficiency, sustainability, and enhanced consumer satisfaction is limitless. The question is, are you prepared to embark on this exciting journey towards success in the ever-evolving digital landscape of CP&R?

Interested in learning more? Download our latest whitepaper for the newest insights on how industry and logistics are merging in the digital realm.