Transforming the CPG industry through digital integration and innovation – interview

The consumer packaged goods (CPG) industry is undergoing a significant transformation, driven by the need for agility, sustainability, and rapid response to changing consumer demands. As consumers increasingly seek health-conscious and sustainable products, manufacturers are under immense pressure to innovate while maintaining high standards of quality and efficiency.

Overcoming disconnected processes in CPG

A key challenge in the CPG sector is the traditional, disconnected approach to product development and manufacturing. Often, companies operate in silos, with each department focusing on its own tasks without a cohesive strategy linking all aspects of the product lifecycle. This fragmented approach can lead to inefficiencies, delays, and challenges in meeting the evolving demands of the market.

Embracing the digital enterprise

To address these issues, the concept of a digital enterprise is being embraced by leading manufacturers. This approach integrates digital and physical processes, creating a seamless digital thread that connects all stages of product development – from initial concept to final production. By weaving this digital thread through every step, companies can enhance traceability, improve lifecycle management, and ensure that they are ready to respond swiftly to market changes.

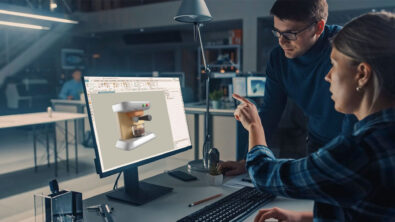

The power of a digital twins

One of the most powerful tools in this digital transformation is the use of digital twins. These virtual replicas of products and processes allow manufacturers to simulate, validate, and optimize their designs before they are implemented in the real world. For example, a digital twin of a product formula can help manufacturers experiment with different ingredients or packaging options, seeing the potential impact of changes in real-time. This not only speeds up the development process but also ensures that the final product meets quality standards and consumer expectations.

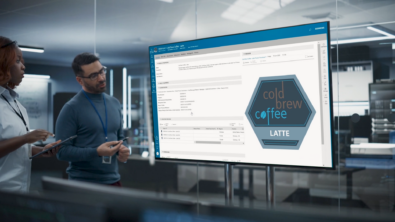

Global standardization and recipe management

Global standardization is another critical aspect of modern CPG manufacturing. With plants spread across the world, each with its unique equipment and resources, ensuring consistent product quality can be challenging. Enterprise recipe management solutions are essential in this context, allowing companies to adapt their recipes to the specific capabilities of each plant while maintaining the integrity and quality of the final product.

The role of automation and cobots

Automation, particularly the use of cobots (collaborative robots), is also playing a crucial role in enhancing efficiency and safety in the CPG industry. In labor-intensive secondary production processes, such as packaging, cobots can work alongside human workers to increase productivity while reducing the risk of injury. This integration of cobots into the production line not only improves efficiency but also accelerates the introduction of new products to the market.

Driving innovation in CPG manufacturing

In conclusion, the digital transformation of the CPG industry is enabling manufacturers to become more agile, sustainable, and responsive to consumer demands. By integrating digital tools and fostering collaboration across departments, companies can navigate the complexities of modern manufacturing and drive innovation.

For a deeper dive into these topics, including expert insights on the challenges and solutions in CPG manufacturing, watch the full interview with Cheyenne Goeminne, Industry Marketing Manager and Kevin Hoorne, Industry Manager from Siemens Digital Industry Software. Their discussion provides valuable perspectives on how digital integration is reshaping the future of CPG.