The secret behind smart manufacturing: What do cold brew coffee, cookies, cupcakes, craft beer, and cola have in common?

Cold brew coffee, cookies, cupcakes, craft beer, and cola—five products that most of us can’t imagine living without. But beyond being tasty staples in our lives, these products share something that’s revolutionizing the way they’re made: smart manufacturing. If you’re in the food and beverage manufacturing industry, you’ve likely heard the term thrown around, but what does it really mean? And why should it matter to you? Let’s dive into how smart manufacturing is changing the game and what it could mean for your operations.

Flexibility is the new recipe for success

In the food and beverage industry, flexibility is more than just a buzzword—it’s becoming essential for staying competitive. Trends shift fast, and consumer demands are more unpredictable than ever. Whether it’s a sudden craze for a new flavor of craft beer or a spike in demand for a healthier cola option, the ability to pivot quickly can make or break a business.

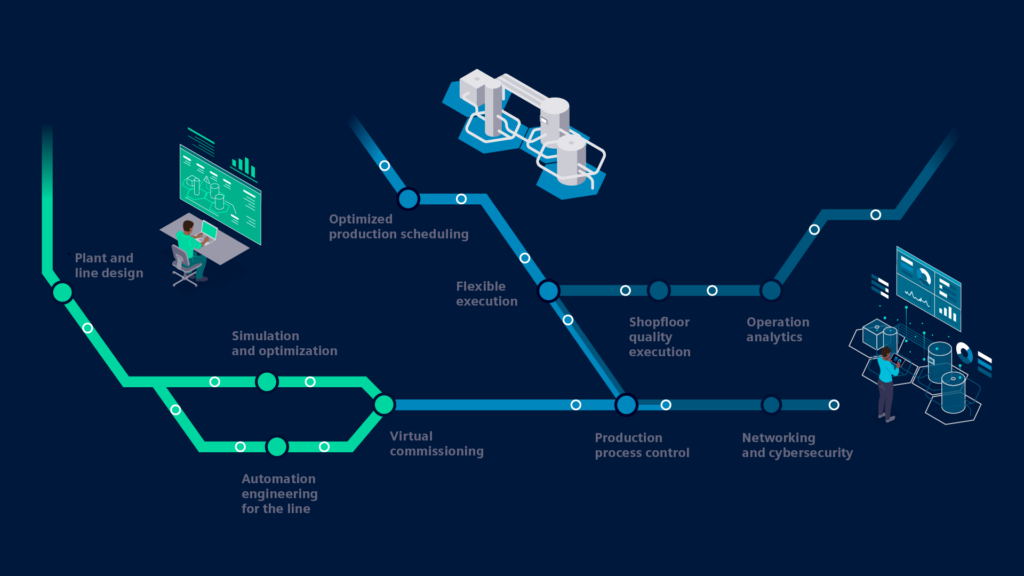

Smart manufacturing is driving this need for flexibility by leveraging automation and digitalization. These advanced technologies allow production lines to adjust in real-time, enabling seamless transitions between different products or variations without the need for extensive reconfiguration. This trend is quickly becoming the industry standard, and companies that embrace flexible manufacturing processes are gaining a substantial edge over those that hesitate.

Smart manufacturing and sustainability: more than just a trend

Sustainability has moved from a niche concern to a central demand in the food and beverage industry. Consumers are increasingly scrutinizing the environmental impact of the products they buy, and companies are being held to higher standards. But here’s the thing: sustainability isn’t just about meeting consumer expectations—it’s also about operational efficiency and long-term viability.

Smart manufacturing, with its emphasis on automation and digitalization, plays a crucial role in achieving sustainability goals. Automation streamlines processes, reducing energy use and waste, while digitalization provides the data-driven insights needed to optimize resource management. For example, in cola production, smart manufacturing can optimize the carbonation process, reducing energy consumption while maintaining that perfect fizz. It’s a win-win: you lower your carbon footprint and cut costs at the same time.

Consistency and quality are non-negotiable

In an industry where the smallest variation can lead to significant waste, maintaining consistency and quality is critical. One off-batch can lead to recalls, lost revenue, and damage to your brand’s reputation. This is where smart manufacturing truly shines.

By using advanced sensors and real-time monitoring, smart manufacturing ensures that every batch of product meets the highest quality standards. Consider the precision needed in coffee roasting—smart systems can control the roasting process down to the exact second, ensuring that every batch has the same rich, full-bodied flavor that your customers expect. This level of control is not just about maintaining standards; it’s about ensuring that your product is consistently top-notch, every time.

Data-driven decision making: making sense of the numbers

Data is everywhere in modern manufacturing, but the real value comes from knowing how to use it. Smart manufacturing systems generate vast amounts of data that can be turned into actionable insights. But what does that mean for you on the factory floor?

Let’s say you’re running a craft beer operation. Smart manufacturing can analyze production data to identify trends, such as which brews are performing best in different regions. This information isn’t just interesting—it’s actionable. You can adjust your production schedules, distribution strategies, and even your marketing efforts based on real-time data. The result? A more agile operation, perfectly aligned with market demands and optimized for production capabilities.

Building consumer trust through transparency

Today’s consumers want more than just a good product—they want to know where it came from, how it was made, and what impact it has on the world. Transparency has evolved from a nice-to-have to a must-have, playing a crucial role in building and sustaining consumer trust.

Smart manufacturing allows for unprecedented levels of transparency in the production process. With technologies like blockchain, you can provide a clear, traceable journey from raw ingredients to finished product. Imagine being able to show your customers exactly where the ingredients in their cookies and cupcakes were sourced, or how their favorite craft beer was brewed, right down to the sustainability practices used along the way. This level of transparency not only meets consumer demand but also sets your brand apart in a crowded market.

The future of food & beverage is smart

As the food and beverage industry continues to evolve, smart manufacturing isn’t just a trend—it’s the way forward. The ability to be flexible, sustainable, consistent, and transparent is becoming a baseline expectation, not just from consumers but from within the industry itself.

Looking ahead, the companies that will lead the market are those that fully embrace smart manufacturing technologies. This approach not only addresses today’s challenges but also positions businesses to adapt to future demands. As digitalization and automation continue to advance, the possibilities for innovation in food and beverage manufacturing are limitless. The question isn’t whether your company should adopt smart manufacturing, but how quickly you can integrate it into your operations to stay ahead of the curve.

Join the conversation

As the demands for flexibility and sustainability in food and beverage manufacturing continue to rise, how is your operation adapting? I’d love to hear your thoughts and experiences—what’s working, and what challenges are you facing?

If you’re looking to enhance your operations with smart manufacturing, Siemens has the expertise and solutions to help. Let’s connect and explore how we can work together to shape the future of food and beverage production.

For more insights on how Siemens is driving transformation in the industry, visit our resource page on smart manufacturing solutions for food and beverage. Discover new ways to integrate flexibility and sustainability into your production processes.