Track decomposition for SAMP processes—What you need to know

By David Abercrombie and Rehab Kotb-Ali – Mentor, A Siemens Business

Understanding key requirements and root causes of errors is critical to successful SAMP manufacturing. IMEC and Mentor provide expert guidance on SADP/SAQP/SALELE track (line) decomposition of design layouts.

If you’ve been following our white paper series with IMEC on self-aligned multi-patterning (SAMP), by now you’ve learned there are multiple SAMP techniques that can be used for metal fabrication at the 5nm node and below:

- self-aligned double patterning (SADP),

- self-aligned quadruple patterning (SAQP),

- self-aligned litho etch litho etch (SALELE).

You also know that the decision to use a particular SAMP process involves a complex trade-off between the various pros and cons of each method.

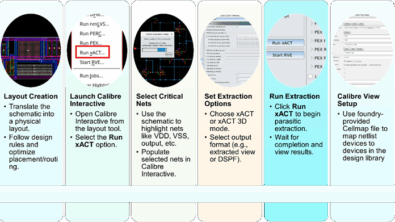

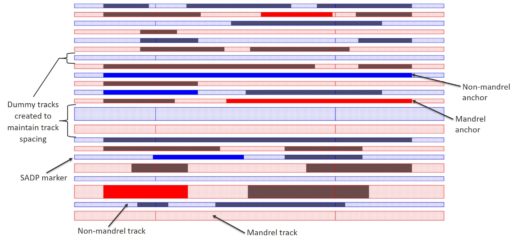

But once you’ve chosen a process, what you really need are the details of how it all works, right? In our latest paper, Self-aligned multi-patterning track decomposition techniques, we explain the critical and optimal layout decomposition requirements you should be employing to produce the required track (line) masks for each SAMP technique (SADP/SAQP/SALELE). We also provide guidance on their associated design rule checks (DRC), and explain how and where errors can occur.

But once you’ve chosen a process, what you really need are the details of how it all works, right? In our latest paper, Self-aligned multi-patterning track decomposition techniques, we explain the critical and optimal layout decomposition requirements you should be employing to produce the required track (line) masks for each SAMP technique (SADP/SAQP/SALELE). We also provide guidance on their associated design rule checks (DRC), and explain how and where errors can occur.

We know that creating a DRC-compliant design for one of these SAMP processes is not a trivial matter. Understanding both the key requirements for generating proper track masks and the root cause of errors that can occur during decomposition are critical to successful manufacturing. To help with the complexity inherent in these processes, the Calibre Multi-Patterning tool not only automates the decomposition process, but helps you and your design team more quickly and accurately understand and debug error conditions when they occur.

If you are working on (or contemplating) designs that require SAMP processes, downloading a copy of this white paper may shorten and simplify what could otherwise be a long and often laborious learning curve.

And yes, before you need to ask, our next paper will address the decomposition requirements and techniques for generating and checking the block (cut) masks. Stay tuned!