The Speed of Reliability

By Dina Medhat – Mentor, A Siemens Business

Electrical overstress (EOS) can damage or destroy an IC. The Calibre PERC reliability platform provides fast, accurate, automated identification of EOS conditions so they can be eliminated before tapeout

Everyone in the integrated circuit business knows that time is money. Meeting tapeout schedules and delivering new products to the market before your competitors are crucial to profitability. But there’s another factor as well—quality. If the products you deliver aren’t reliable, or they fail to perform as promised, all that hard work to get them out on schedule is wasted.

Achieving the balance between quality and time isn’t getting any easier, either. New applications, such as automotive and medical, are creating reliability and performance demands above and beyond the norm. The new standard of success, then, is the ability to deliver designs that will operate reliably and predictably under these demanding conditions. Whether you’re delivering brand-new designs for these applications, or reengineering your existing products, you’re facing a whole slew of new verification challenges, like electrical overstress (EOS) detection.

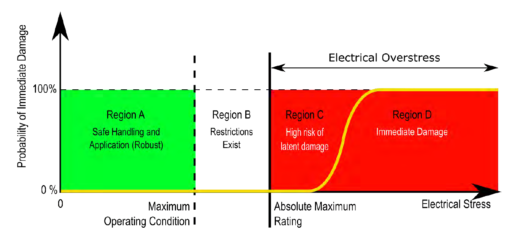

EOS is one of the leading causes of IC reliability failures. EOS events can result in varying degrees of performance degradation, all the way up to catastrophic damage. Identifying and removing EOS susceptibility from IC designs is essential to ensuring successful product performance and reliability, but design constructs that contribute to EOS sensitivity can be extremely subtle. In addition to standard verification processes, engineers need new tools and processes to help them ferret out EOS vulnerabilities that can contribute to performance degradation and early failure.

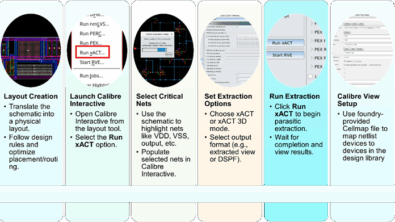

The Calibre® PERC™ reliability platform incorporates an innovative capability called voltage propagation that enables designers to perform fast, automated EOS detection and prevention. The basic concept of voltage propagation is simple: designers define voltages, then define rules to propagate these voltages to internal nodes in a static way to catch any violations. The voltage propagation functionality is both powerful and flexible, because you can define unique propagation rules based on your design needs. From a debugging perspective, you can use the Calibre RVE™ results viewer to interactively trace voltages, giving you a better understanding of how they were propagated on your design, which enables you to debug errors more quickly and efficiently.

The Calibre® PERC™ reliability platform incorporates an innovative capability called voltage propagation that enables designers to perform fast, automated EOS detection and prevention. The basic concept of voltage propagation is simple: designers define voltages, then define rules to propagate these voltages to internal nodes in a static way to catch any violations. The voltage propagation functionality is both powerful and flexible, because you can define unique propagation rules based on your design needs. From a debugging perspective, you can use the Calibre RVE™ results viewer to interactively trace voltages, giving you a better understanding of how they were propagated on your design, which enables you to debug errors more quickly and efficiently.

In addition to EOS detection, multiple design verification issues can be addressed with voltage propagation, including voltage-aware design rule checking (DRC) constraints, and multi-power domain crossings. Fast, accurate identification of reliability conditions in a design lets designers analyze and correct the design early in the verification flow, when fixes can be applied more easily, and at a lower cost.

To learn more about using the Calibre PERC reliability platform for EOS detection, check out our white paper, Protecting Against IC Reliability Failures with Automated Voltage Propagation. It provides a detailed look at EOS causes, and how you can eliminate them from your designs quickly and efficiently. The speed of reliability has never been faster…