What are software-defined vehicles? Breaking down the basics and why they’re important

In the rapidly evolving automotive industry, the term “software-defined vehicles” (SDVs) has become a focal point of innovation and discussion. But what exactly are SDVs, and why are they pivotal to the future of transportation? This article delves into the fundamentals of SDVs, contrasting them with traditional vehicles and explaining their significance in modern automotive advancement.

1. Introduction to software-defined vehicles

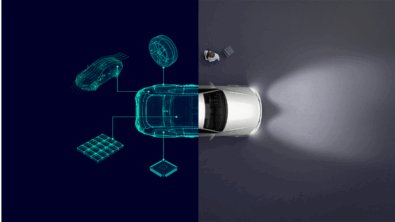

Software-defined vehicles represent a transformative shift in automotive design and functionality. Unlike traditional vehicles, where hardware components dictate capabilities, SDVs leverage software to control and enhance vehicle operations. This paradigm allows for continuous updates, customization, and integration of advanced features, positioning SDVs at the forefront of automotive innovation.

The shift to software-defined vehicles marks a revolutionary change in the automotive industry, fundamentally altering how vehicles are conceived, developed, and maintained. Traditional engineering processes, where hardware and software development occur sequentially in disconnected departments, have led to significant challenges, including integration issues, extended development cycles, and post-sale problems resulting in warranty issues and recalls.

The automotive industry’s transition to SDVs has necessitated the development of comprehensive, cloud-based frameworks powered by advanced digital twin technology. These sophisticated systems address critical integration and validation challenges while accelerating software development and feature implementation.

Traditional vehicles vs. software-defined vehicles

In traditional vehicles, functionalities are predominantly hardware-driven, with features such as braking, steering, and vehicle dynamics and safety systems managed by dedicated hardware components with limited flexibility. This conventional approach has served the automotive industry well for decades, but these features no longer deliver the necessary differentiation to stay ahead of the competition, especially in our rapidly evolving digital world.

Conversely, SDVs utilize centralized computing systems where software governs these functions, enabling unprecedented flexibility and upgradeability. This architectural shift represents a fundamental change in how vehicles are designed and maintained through integrated software development. The decoupling of hardware and software development processes has revolutionized the industry, enabling parallel development tracks that significantly reduce time-to-market and development costs.

2. Core technologies enabling SDVs

The foundation of SDVs rests upon several key technologies:

- Centralized computing architecture: Modern SDVs employ powerful vehicle computing platforms that manage various vehicle functions.

- Digital twin technology: Siemens Xcelerator platform enables comprehensive and continuous virtual validation.

- Artificial intelligence (AI) and machine learning (ML): These technologies enable predictive maintenance, adaptive driver assistance systems, and personalized user settings.

- Model-based systems engineering (MBSE): Streamlines SDV development by unifying hardware and software for reliable system integration.

3. Benefits of software-defined vehicles

The transformation to software-defined vehicles has revolutionized automotive development through integrated software solutions. Key benefits include:

- Enhanced flexibility: Software-driven functionalities through model-based systems engineering

- Continuous improvement: OTA updates enabled by advanced software management

- Cost efficiency: Streamlined development through digital twin technology

- Improved safety and security: Enhanced through comprehensive validation solutions

The integrated framework approach enables manufacturers to manage the entire vehicle lifecycle seamlessly, fostering unprecedented collaboration between suppliers and partners. Through Siemens Xcelerator, manufacturers can identify and address problems before they manifest in physical prototypes, significantly improving quality and reliability.

Remote commissioning capabilities, made possible through the integration of PLM and ALM systems, have transformed how vehicles are updated and maintained.

4. Challenges in implementing SDVs

The transition to software-defined vehicles presents complex challenges that can be addressed through comprehensive solutions:

- Integration complexities: A unified development platform can ensure seamless interaction between hardware and software components.

- Development cycle management: Timelines can be compressed using advanced PLM solutions to coordinate parallel development.

- Validation and testing: Simulation with Siemens Simcenter adds efficiency and confidence to validation by enabling virtual, hybrid and physical testing.

- Cybersecurity risks: Increased connectivity exposes vehicles to potential cyber threats, necessitating robust security measures.

- Regulatory compliance: Siemens’ unified SDV development platform delivers full traceability and continuous verification to ensure compliance.

- Infrastructure requirements: Implementing SDVs requires advanced infrastructure, including high-speed internet and compatible communication networks.

- Consumer acceptance: Educating consumers about the benefits of SDVs and addressing concerns related to data privacy and security are crucial for widespread adoption.

5. Real-world applications

The implementation of SDV technology has revolutionized automotive development through Siemens’ comprehensive solutions. Major automotive manufacturers are leveraging:

- Vehicle control systems powered by embedded software solutions that optimize performance, enable real-time decision-making, and ensure safe and efficient driving.

- Over-the-air (OTA) updates that leverage comprehensive software management systems to deliver wireless upgrades, security patches, and new features.

- Advanced connectivity that integrates connected vehicle solutions to support seamless vehicle-to-everything (V2X) communication and enhanced mobility services.

- Predictive maintenance solutions that use real-time vehicle data and analytics to prevent breakdowns and reduce downtime.

- Autonomous driving and advanced driver-assistance systems (ADAS) to enhance safety, efficiency, and driver convenience.

6. The future of automotive innovation with SDVs

The evolution of software-defined vehicles points toward an increasingly connected future enabled by Siemens’ automotive solutions. Key developments include:

- Advanced simulation capabilities through Simcenter

- Integrated development environments via Teamcenter

- Enhanced software management using Capital Software

- Electronic design systems (EDS) for chip development (PAVE360)

The development of integrated ecosystems will continue to reshape the automotive industry through Siemens Xcelerator, fostering innovation and enabling new business models.

7. Frequently asked questions (FAQs)

Q: What is a software-defined vehicle (SDV)?

A: An SDV is a vehicle where software controls and manages advanced functions, allowing for continuous updates and customization.

Q: How do SDVs differ from traditional vehicles?

A: Traditional vehicles rely on hardware for functionalities, while SDVs use software, enabling features like OTA updates and real-time diagnostics.

Q: What are the benefits of SDVs?

A: SDVs offer enhanced flexibility, continuous improvement through updates, cost efficiency, and improved safety and security.

Q: What challenges do SDVs face?

A: Challenges include cybersecurity risks, regulatory compliance, infrastructure requirements, and consumer acceptance.