Mastering cloud-based QMS solution for micromobility manufacturers

How can micromobility manufacturers leverage a cloud-based QMS (Quality Management System) solution to innovate faster, support quality management?

In today’s automotive and micro-mobility landscape, small and mid-sized manufacturers are under more pressure than ever. Products are getting more complex. Customers want greater customization. And quality expectations are sky-high and the need for smart manufacturing has never been more urgent.

Yet unlike their enterprise-sized competitors, these businesses don’t have massive teams or bottomless budgets to throw at the problem. Teams are often stretched thin, juggling spreadsheets, siloed systems and last-minute changes that threaten delivery timelines and margins.

Quality issues caught too late can mean rework, wasted material, or, even worse, a customer complaint. Every decision matters, and there’s little room for error.

Key challenges for micromobility manufacturers

Manufacturers of all sizes are testing their resilience and adaptability to get innovative products to market faster.

As micromobility manufacturers, you face distinct challenges pushing your lean organization to compete with enterprise companies, such as increasing product complexity, production and operational costs, supply chain uncertainties, talent gaps, cybersecurity and sustainability.

Meeting these expectations requires finding a way to access the same cutting-edge technologies and skilled workforce as competitors.

As small and medium business (SMB) micromobility manufacturers, agility and flexibility are key competitive advantages. However, product complexity and production costs are rising, and traditional manufacturing processes may no longer yield the productivity levels and profit margins.

A shortage of skilled labor, supply chain disruptions and difficulties meeting stricter quality, sustainability, health and safety and cyber security standards and regulations compound these challenges. Micromobility manufacturers need to adapt to today’s climate.

How micromobility manufacturers streamline operations while protecting quality

By transforming daily operations via digitalization and collaboration, micromobility manufacturers can synchronize quality, engineering and manufacturing. This will leave you ready to respond quickly to production, delivery and quality demands.

What micromobility manufacturers need is scalable, cost-effective digital tools. Leveraging software as a service (SaaS)-enabled solutions can provide access to advanced technologies without needing substantial upfront investment. Cloud platforms enable real-time collaboration, improving efficiency across the organization and offering flexible scaling as the business grows.

Boosting micromobility manufacturers efficiency with a cloud-based QMS solution

Relying on traditional manufacturing processes and standalone applications is no longer effective in meeting varying customer needs. In today’s fast-paced markets, not delivering rapidly and at scale caused by unplanned downtime leaves you at a disadvantage. Micromobility manufacturers need flexibility to quickly adapt and produce a wide range of complex products without risking quality or compliance issues. Maintaining the competitive advantage requires full control, flexibility and visibility into all phases of your engineering and manufacturing operations.

By synchronizing processes and data and enabling teams to work together from design to manufacturing, micromobility manufacturers can increase efficiency while reacting to changing customer demands, managing costs and improving quality.

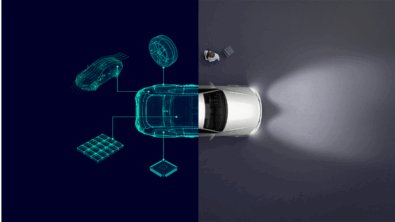

A cloud-based quality management system (QMS) provides a standardized, centralized and strategic approach that offers visibility into quality-related metrics, from planning to delivery. Micromobility manufacturers can break down silos and improve collaboration, synchronizing product development and quality management to maximize the value of change process capabilities.

Embedding cloud-based QMS from virtual planning to realization

A closed-loop quality (CLQ) system facilitates collaboration between departments, fostering alignment in key business processes for micromobility manufacturers.

By enabling manufacturing engineering teams to visualize outcomes in virtual realms, all stakeholders can access contextualized product design and assembly information, supporting cross-functional collaboration.

A CLQ system also facilitates a holistic approach to maintaining high-quality standards across manufacturing operations, allowing real-time capture of production-quality data by monitoring quality according to specified control and inspection plans. This data enables faster adjustments in the micromobility manufacturing environment, helping prevent quality issues before they arise.

Realize a closed-loop quality approach for micromobility manufacturers

A CLQ system supports a holistic approach from engineering to manufacturing operations, providing manufacturers with the necessary procedures, processes and resources to meet customer requirements and adhere to standards and industry guidelines.

Design and plan quality: In customer-driven product development, quality teams can reuse engineering data, such as computer-aided design (CAD) models, with product manufacturing information (PMI). They can also implement effective quality project management and closely monitor key milestones and quality gates. Additionally, they can conduct risk assessments with failure mode and effects analysis (FMEA) to identify and mitigate potential quality design and process problems for smoother operations.

Maintain control over key characteristics: Micromobility manufacturers should classify product or process characteristics and define inspections to monitor them effectively. By identifying appropriate controls, manufacturers can monitor characteristics at various production stages to detect any deviations or defects.

Secure quality control throughout production: Define, plan and perform inspections for incoming materials, parts and finished products. Analyze data using statistical process control (SPC) tools. Detect product and process deviations and create nonconformances.

Enhance change management to boost quality improvements: Accelerate your continuous improvement journey by implementing a seamless problem-solving process that engages all stakeholders. Empower your team to initiate change requests directly from the quality department and reach the right stakeholders without delay.

Strengthen collaboration with your suppliers: A closed-loop QMS strengthens supplier collaboration by addressing and documenting deviations as quality issues and streamlining data exchange for part approval processes.

Accelerate time-to-market while achieving compliance: Conducting audits is crucial for identifying room of improvements and streamlining third-party certifications. Additionally, you can manage the training and qualification process for employees.

Leveraging Siemens Xcelerator solutions for quality management

Enhance core quality processes and production with the cloud-based Siemens QMS solution, which is part of the Siemens Xcelerator business platform, a comprehensive offering of software, hardware, and services.

Using Teamcenter® X Quality helps you meet the highest standards and exceed customer expectations. This comprehensive digital solution, native to the Teamcenter platform, empowers you to kick-start your quality project and promptly realize its value by leveraging core quality tools, such as FMEA, problem-solving, audit, and so on.

Leveraging Opcenter™ X Quality enables micromobility manufacturers to streamline inspection planning, data acquisition, statistical process control and nonconformance management. This improves quality, compliance and operational efficiency across shopfloor operations.

Drive innovation and excellence for micromobility manufacturers

Smart manufacturing for micromobility innovation has become essential. With Siemens Digital Industries Software’s smart manufacturing solutions, micromobility manufacturers can enable a digital closed-loop quality management process, embedding quality at the core of development and production.

Ready to shape the future of micromobility?

Explore Siemens’ quality management solutions at siemens.com/qms to embark on your quality transformation journey today.