Smart manufacturing drives sustainable operational excellence in automotive

In a world racing towards the future, automotive leaders are not just keeping pace but setting their speed. Today’s mission is to electrify and automate mobility faster and smarter than ever. But with great innovation comes great challenges. Rethinking factories for electric vehicle production, retraining for new technology, and managing complex supply chains are hurdles in your path. Downtime in the plant and compromising quality or sustainability standards are not options. Enter Siemens Smart Manufacturing, a solution curated specifically for the automotive industry.

Watch the video to learn how you can transform your automotive manufacturing operations with cutting-edge manufacturing solutions to deliver high-quality products on time, all the time.

Complete your digitization journey to overcome manufacturing challenges

With Siemens Smart Manufacturing solutions, you can virtually plan and validate work cells, lines, automation, and entire plants to ensure your first design is always right. To avoid costly downtime, you can ramp up quickly after new product launches and during line changeovers. And, throughout production, you can keep your line running safely, efficiently, and securely to produce high-quality products on time, all the time.

Avoid downtime and costly delays

Often, manufacturing new products means upgrading equipment, integrating new technologies into production lines, and training staff to work with advanced systems. However, disconnections between processes, people, and automation will negatively affect quality, cost, and timing without proper planning and optimization. This can be avoided by designing the entire production line in a digital realm. Every aspect can be simulated, from robotic arms’ movement to future components’ smooth flow. This virtual validation ensures that the transition from digital to real-world will be flawless.

Adapt operations to accommodate new production

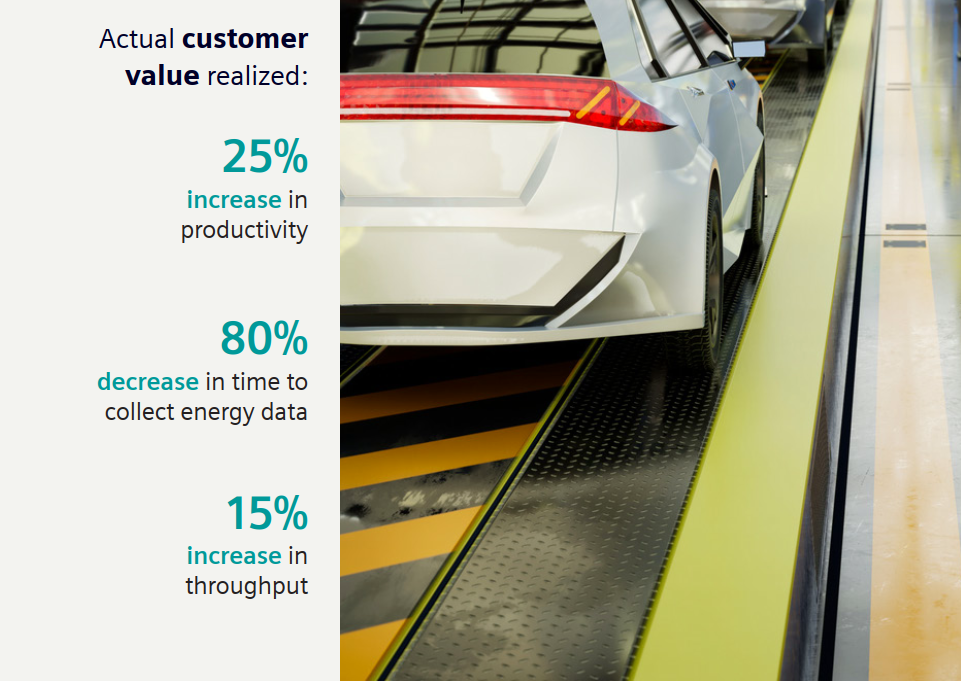

Even in current facilities, EV production often requires greenfield lines and unique skill sets to accommodate new processes, components, and increased vehicle weight. Incorporating advanced automation that works in sync with manufacturing technologies and systems drives a successful integration of operational and information technology. This IT/OT merger creates a more efficient, responsive, and data-driven production environment where personnel can be trained faster, productivity can be increased, and additional flexibility allows you to respond rapidly to market changes.

Fully leverage operational data for maximum benefits

In today’s highly competitive market, the ability to efficiently collect and analyze data to improve operations is becoming a key differentiator, and those failing to embrace this are at a significant disadvantage. Many automakers are already collecting operational data, but few use it to their full potential. With a closed-loop system, every vehicle and component can be tracked and analyzed for quality, with feedback immediately looping back into the production process. Additionally, every manufacturing process can be analyzed and adjusted in real time for maximum efficiency. This ensures every product rolls off the line on time and meets strict quality standards.

Pair technology and automation for seamless IT/OT integration

Our Smart Manufacturing solutions are specifically curated for the automotive industry, offering the unique benefit of advanced automation and intelligent technologies that have been developed to work seamlessly together.