Realizing reliable microelectronic systems

1. Challenge: Microelectronic systems need to be reliable

The sustainability of the market for Electronic Components and Systems (ECS) depends on their reliability. The European ECS industry must comply with EU rules on repair and reuse1, which require manufacturers to make their products repairable for at least ten years after market introduction and to increase the reliability of their products. This can be achieved by improving our understanding of the complex physics of degradation over the entire value chain, developing accurate Digital Twins (DTs) with a strong coupling to the product and delivering AI-based reliability assessment tools that allow an improved and accelerated design for reliability.

The reliability of microelectronics is strongly affected by operational temperatures during their lifetime. Temperature variations make the materials expand and contract at different rates, causing internal stresses and fatigue that ultimately lead to failures, like cracks in the electrical interconnections, warpage, delamination, etc., accounting for about 55% of failure causes.

Reliability improvement is possible by sensing temperatures, in turn enabling improvement of thermal management, and by predicting the Remaining Useful Life (RUL), for a paradigm shift from preventive to predictive maintenance. To achieve such a goal, Digital Twins and Physics of Degradation models can be jointly used.

2. Solution: Research into combining simulation and sensing

Within MIRELAI, an EU-funded Marie Skłodowska-Curie research project addressing the challenges of reliability in electronics, Siemens and Imec together perform research to monitor the RUL, exploring both physics and data-driven approaches. Two different research paths are being pursued. The first path investigates Digital Twins for Thermal Virtual Sensing, aimed at estimating in-operation temperatures. The second path focuses on RUL prediction, adopting Machine Learning techniques and Physics of degradation models. It is envisaged that the two paths will meet in the future, as the estimated temperatures can serve as input for the RUL prediction.

Thermal Virtual Sensing (TVS) aims at obtaining a full understanding of the temperatures in an electronic system using a few sensors, while in operation. This technology is enabled by addressing the following challenges:

- Defining a suitable mathematical model

- Managing model uncertainties

- Selecting informative locations for sensors.

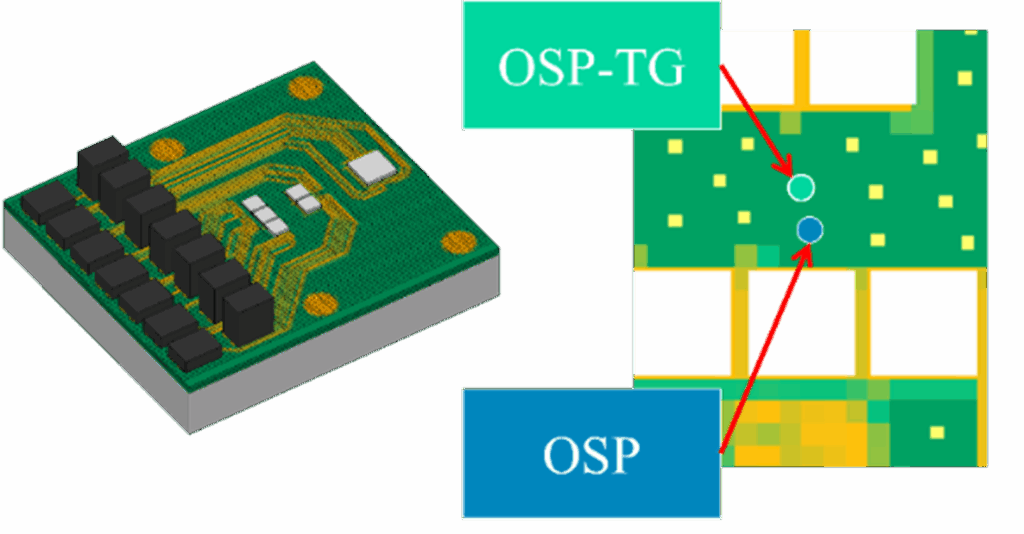

Reduced Order Models (ROM) are investigated to ensure real-time execution and high detail, meaning that the entire temperature distribution of the considered electronic system is determined. To deal with model errors that can appear during the system’s lifetime, the Augmented Kalman Filter (AKF) serves as a framework merging the virtual world of the model with the real world of measurement data coming from the system in operation. To make sure TVS is effective, measurement data should come from informative and reliable locations selected by executing an Optimal Sensor Placement (OSP) algorithm.

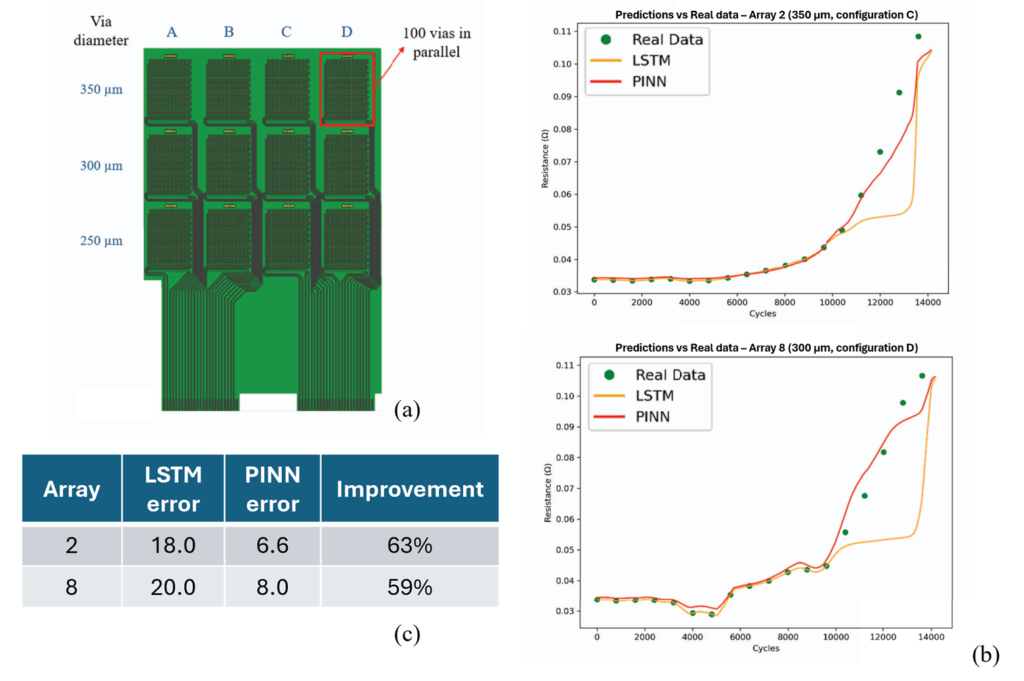

The prediction of Remaining Useful Life can be enabled by combining data-driven methods with multi-physical insight. Traditional Long Short-Term Memory (LSTM) networks are trained on experimental time-series of a critical lifetime indicator to predict degradation trends. Feed-Forward Neural Networks (FFNNs) are trained on lifetime distribution data evaluated for different combinations of material and geometrical parameters using FEM simulated data and empirical fatigue models. Building on these foundations, a Physics-Informed Neural Network (PINN) integrates physics directly into the learning process, merging the strengths of data and simulation to deliver more reliable and interpretable lifetime predictions.

3. Results

Preliminary results are available from investigating the two approaches on different systems, which already highlight their potential. In the first case, we explore the estimation of the Heat Transfer Coefficient (HTC)2, an inherently uncertain parameter which can highly affect the temperatures of a system. In the second case, we predict the lifetime by observing the variation of electrical resistance as a health condition indicator3.

3.1 Results for thermal virtual sensing

The estimation performance of HTC with a Digital Twin (DT) depends on the sensing locations. Faster estimation can be achieved by selecting informative sensing locations using an OSP algorithm. Unfortunately, in electronics, the most informative sensing locations are usually close to chips and therefore unreliable due to steep spatial temperature variations, i.e. Thermal Gradients (TG). The OSP algorithm can be informed of TG, such that it selects more reliable sensing locations.

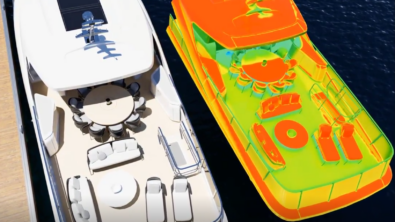

We validated the methodology against sensor location shift. This means that the simulation data used as measurement was from a slightly displaced location than the corresponding location in the model adopted in the DT. The reference profile of the parameter is well tracked when using the sensor selected by the TG-informed OSP, as can be seen in Figure 1.

3.2 Results for lifetime (RUL) prediction

The PINN enables accurate and explainable lifetime prediction of Plated Through Holes (PTHs), the most fatigue-sensitive interconnects in Printed Circuit Boards (PCBs). By merging simulation-based physics knowledge with experimental degradation data, the model captures the real behavior of PTHs under thermal cycling, reproducing the resistance evolution with remarkable precision (see Figure 2). Compared to a purely data-driven approach, the integration of physical constraints reduces the prediction error by more than 60%, achieving consistent prediction of the real-life degradation trends. This approach provides accurate insight into the system performance, which is key towards faster design iterations. This paves the way for predictive maintenance strategies in microelectronics, promising reduced costs and improved reliability of future electronic systems.

4. Conclusions and outlook

Industry needs to comply with electronics reliability standards and regulations that become ever stricter in order to meet goals on sustainability and safety. Siemens and Imec perform research to realize more reliable microelectronics systems, investigating both physics-based and data-driven approaches, in the frame of the EC research project MIRELAI. Specifically, through the presented work, we target predictive maintenance to become feasible in an industrial application context. The aim is to predict the Remaining Useful Life (RUL) of electronics using physics-powered Machine Learning and Digital Twins in order to improve ECS sustainability. Although the methodology R&D is still in the initial research stage, we already present promising results that demonstrate the potential for future industry adoption. This research also paves the way to broaden the application range of Executable Digital Twins (xDT)4, e.g. enabling Smart Virtual Sensing5 to thermomechanical applications for microelectronics systems and beyond6.

Acknowledgements

The European Commission is gratefully acknowledged for funding the Horizon Europe research and innovation programme, which includes the support for the Marie Skłodowska-Curie Action (MSCA), including the Industrial Doctoral Network MIRELAI (MIcroelectronics RELiability driven by Artificial Intelligence) with Grant agreement ID 101072491.

MIRELAI has the ambition to address the challenges of reliability, sustainability, and verification efforts related to the production of microelectronics components, and boost Europe’s innovation capacity and competitiveness in the market. To achieve this goal, the project recruited 13 doctoral candidates (DCs) to investigate the physics of degradation and reduce testing and verification efforts across the value chain of electronic components and systems, while providing invaluable skills to the next generation of engineers.

References

- EC, Towards a more sustainable single market for business and consumers,

document IMCO-PR-650478_EN, 2020/2021(IN), May 13, 2020. ↩︎ - Depaola, M., De Gregoriis, D., Bornoff, R., Vandevelde, B., & Moens, D., Optimal Sensor Placement for Thermal Virtual Sensing in Electronic Systems Using Augmented Kalman Filtering. Proc. 31st International Workshop on Thermal Investigations of ICs and Systems (THERMINIC), 1-6, 2025. ↩︎

- Sperti, M., Nawghane, C., Vandevelde, B., Lammens, N., & Verbeke, M.,Physics-Informed Machine Learning-Based Methodology for Plated Through Holes Lifetime Estimation in Printed Circuit Boards. Proc. 26th International Conference on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems (EuroSimE), 1-10, 2025. ↩︎

- Scurria, L., Kothlow, C., Simcenter Executable Digital Twin – The leap forward in digital twin technology, Simcenter Blog, April 28, 2025. ↩︎

- Kou, X., Melvin, J.: Simcenter 3D Smart Virtual Sensing – Unveiling the Magic, Simcenter Blog, January 15, 2024. ↩︎

- Siemens Digital Industries Software, Simcenter 3D, Retrieved 2026. ↩︎