Streamline the aircraft certification process – Part 2: Establishing a traceable chain of data

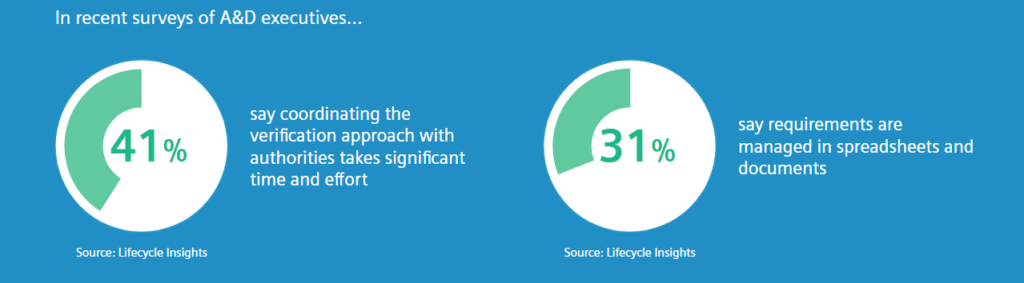

Aircraft certification requires precise documentation, verification and design change tracking. However, many aerospace companies rely on disconnected spreadsheets and manual processes, making traceability difficult. Without a continuous, auditable chain of data, proving compliance is time-consuming and error-prone.

How a digital thread transforms certification traceability

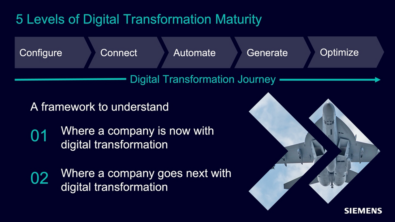

This blog is part two of a three-part series on modernizing aircraft certification:

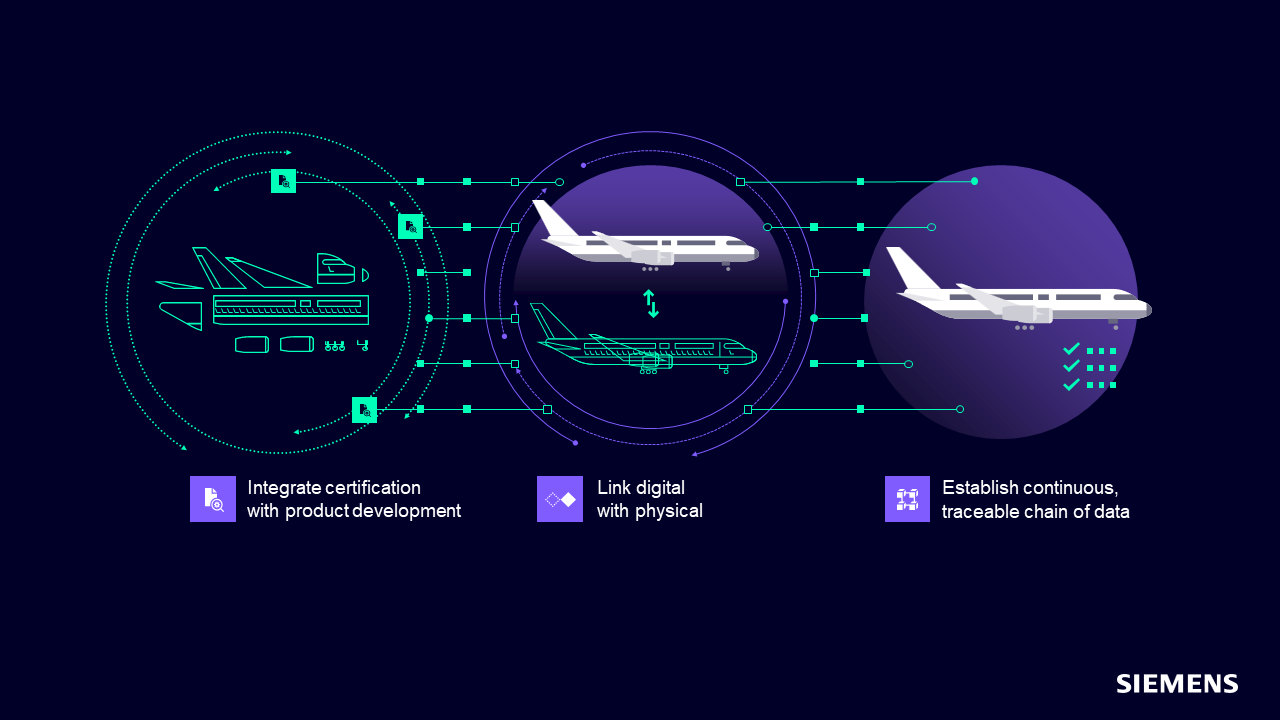

- Integrating certification with product development

- Establishing a continuous, traceable chain of data

- Linking the digital with the physical

This post focuses on the second key element: Creating a connected, traceable chain of data for certification.

The reality of aircraft certification challenges

Aerospace teams often face fragmented compliance tracking. Engineers design components to meet regulatory requirements, while certification teams manually document those requirements in separate systems. When a regulatory audit requests proof of compliance, teams scramble to gather verification records, test results and design documentation from multiple sources, leading to wasted time and potential setbacks.

A digital thread approach can help eliminate these inefficiencies by connecting certification data in real time. Teams can instantly trace every requirement, design change and verification result, streamlining compliance and reducing certification delays.

Achieving traceability without adding complexity

Many teams fear that increasing compliance tracking will introduce administrative burdens. However, achieving seamless traceability is not about adding processes but connecting existing data through a digital thread.

By integrating compliance into daily workflows, organizations can maintain full traceability without creating more work. A digital thread centralizes certification data, enabling real-time updates, automated tracking and audit-ready documentation, allowing teams to focus on design, development and production.

Strategies for creating a continuous, traceable chain of data for aircraft certification

A seamless, auditable certification process requires structured traceability. Aerospace companies can achieve this by focusing on three key steps:

- Integrating all requirements directly with product designs and enabling cross-domain data integration

- Enhancing product feedback and change management through a traceable data flow between design and BOM

- Managing the as-maintained BOM and establishing service planning

Digital tools to simplify and accelerate the aircraft certification process

With Siemens Xcelerator, aerospace and defense companies are moving beyond outdated compliance processes. By integrating automation, traceability and virtual validation, teams can reduce manual work, improve accuracy and certify faster.

- Eliminate compliance bottlenecks with automated workflows that keep regulatory data up to date.

- Achieve full traceability by linking design, requirements and verification into a single connected system.

- Validate faster with digital twins, minimizing reliance on physical prototypes and expediting approvals.

With a connected, traceable chain of data, A&D companies can bring certified, high-quality products to market with greater speed and confidence.

Up next in the aerospace certification series

In Part 3, we’ll explore linking the digital with the physical, using virtual simulations and real-world testing to create a seamless compliance ecosystem.

Looking for more insight? Dive into more aircraft certification resources, including case studies and FAQs, here. Missed Part 1 of this series? You can catch up here.