Developing a clear vision for digital transformation maturity

Digital transformation is reshaping industries globally, and in the aerospace and defense (A&D) industry, it is critical for improving efficiency, product development and manufacturing processes. As demand for more innovative and complex products increases, companies must accelerate their digital transformation efforts to remain competitive. However, despite significant investments, many aerospace companies are struggling to see the expected return on investment (ROI). This blog explores where companies are in their digital transformation maturity, drawing insights from Siemens’ “Five Levels of Digital Transformation Maturity” roadmap that allows A&D companies to build more optimized products faster. The blog also explores the results of the A&D Digital Transformation Report.

Understanding aerospace digital transformation maturity

Digital transformation maturity refers to how extensively a company has integrated digital processes across its operations. The goal is to move beyond simply digitizing existing workflows to fundamentally transforming how a company operates and delivers value. Siemens has developed a five-step framework to guide aerospace companies on this journey, helping them assess their progress and take the next steps on their digital transformation journey.

- Configure

- Connect

- Automate

- Generate

- Optimize

The first step in this framework is configure, which involves transitioning from document-based workflows to model-based systems. This means managing product data in a way that ensures all relevant information is centrally stored and easily accessible throughout the product lifecycle. By moving to a model-based approach, companies can begin to streamline their operations and improve the accuracy and reusability of their data.

Next is the connect phase, where companies bridge their data across multiple domains, creating a single source of truth for the entire product lifecycle. This includes connecting data from design, testing, manufacturing and support, ensuring that all stakeholders are working with the most accurate and up-to-date information. Many companies currently find themselves at this stage, where digital tools are in place but not yet fully optimized. To unlock the full benefits of digital transformation, companies must continue progressing through the next stages.

Automate is the third phase and lies at the core of digital transformation. Automation frees engineers and workers from tedious, repetitive tasks, allowing them to focus on more valuable and creative aspects of their roles. There are two parts to automation: automating the mundane tasks that humans don’t want to do and automating complex tasks that we thought only humans could do.

This starts by automating mundane tasks involved with configuration and connection and then automating aspects such as report and requirement development. Siemens already has customers using rules-based algorithms to auto generate wiring diagrams and other electrical support material that saves customers thousands of hours per aircraft. Once a company has automated the mundane, they are on their way to creating a better work environment that more engineers will want to be a part of. More than just increasing efficiency, this attracts new talent and reduces attrition.

Once mundane engineering processes are automated, the next aspect of this is to automate complex engineering, development and manufacturing processes. This leads to the fourth step: generate.

In the generate phase, companies can leverage advanced technologies like generative design to explore multiple design alternatives based on predefined parameters. This approach is not limited to product design but extends to the development of factories and manufacturing processes as well. Engineers and planners can now quickly evaluate various production layouts, equipment configurations and material flows to optimize factory development alongside product design. By generating multiple options for parts and manufacturing processes, teams can accelerate decision-making in production planning, factory setup and execution. For example, generative design can suggest optimized workflows that reduce cycle times, minimize material waste or improve assembly efficiency. While generating the design for an entire aircraft remains a long-term goal, significant progress is already being made in generating optimized designs for individual parts, subsystems, and manufacturing processes, making the entire production lifecycle more agile and data-driven.

Finally, the optimize phase involves utilizing the comprehensive digital twin and other advanced tools to refine and perfect designs. This phase closes the loop on digital transformation by evaluating multiple alternatives against KPIs and using simulations to predict how a product will perform before it is physically built. By the time a product reaches the manufacturing stage, it has already undergone countless virtual iterations, ensuring the final version is as close to optimal as possible. This not only reduces production costs but also shortens time to market and minimizes the risk of costly errors.

Aerospace digital transformation key findings

Siemens sponsored a survey across the Aviation Week network to provide valuable insights into how aerospace companies are progressing on their digital transformation journey. In October of 2024, Todd Tuthill, Vice President of Aerospace, Defense, and Marine Industry at Siemens Digital Industries Software discussed the findings from this survey and the five levels of digital transformation maturity roadmap at the Aviation Week Digital Transformation Summit that happened October 8-9 in Southlake, Texas. You can download the slides from Todd’s prestation here: Developing a Clear Vision for Digital Transformation Maturity.

The survey, which included responses from A&D professionals (many of which are OEMs and tier 1,2 and 3 suppliers), reveals that while many companies have made progress, most are still struggling to realize the full potential of their digital transformation capabilities.

One of the key findings from the survey found that 55 percent of respondents consider their digital transformation efforts to be mature or complete. Half or more of all respondents expected digital transformation to help them save costs, increase efficiency and develop products faster.

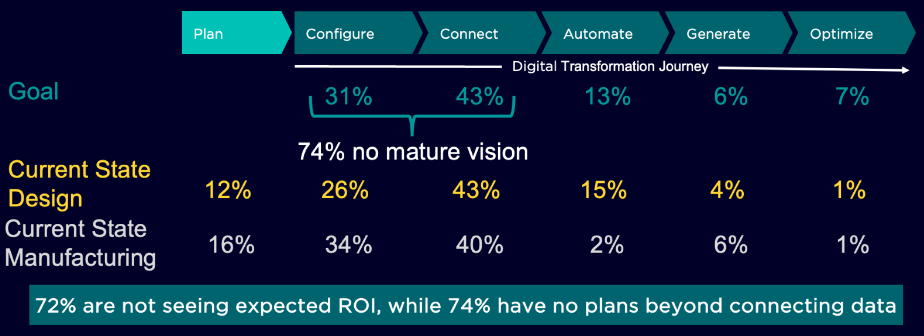

However, despite the data above, 72 percent of companies reported that they have not yet seen the expected ROI from their digital transformation initiatives. This disconnect suggests that while companies have invested heavily in digital tools and processes, many are not leveraging them to their full potential.

The survey also reveals that many companies are stuck in the “connect” phase of digital transformation. Over 70 percent of respondents indicated that their design groups are either configuring or connecting data, but only 20 percent have moved beyond this stage to more advanced phases like automation or optimization. This indicates a significant gap between where companies are and where they need to be to fully benefit from digital transformation.

A graph showing the goal, current state of design and current state of manufacturing from the survey.

The expected benefits of digital transformation are clear: 60 percent of respondents believe it will help reduce costs, while 50 percent expect it to make their workforce more efficient. Other major drivers are faster time to market and the ability to develop more complex products. However, the most common challenges include disconnected tools and underestimated scope, both of which are preventing companies from achieving these benefits.

How can you move your aerospace company beyond the “connect” stage?

For many A&D companies, the biggest challenge is moving beyond the “connect” phase in the five steps to digital transformation. While connecting data and systems is an important foundation, the true value of digital transformation lies in what companies can achieve once data is connected. Technologies like the digital thread, comprehensive digital twin, AI and immersive engineering are key to overcoming these. However, without the right people, processes and tools in place, adopting these technologies is impossible. It’s essential to bring employees along on this journey, making them a part of the change. Everyone must be on board with adopting and embracing new ways of working to ensure a successful transformation.

Aerospace digital thread

Digital threads are essential in the A&D industry because they bridge the numerous silos that exist across different teams and data sets. In typical aerospace companies, different departments, such as high-level system architecture, design, testing, manufacturing and operations, often work in isolation, each using their own tools and datasets. These silos can hinder collaboration and slow down processes, making it difficult to adapt quickly to changes, such as incorporating new sensors based on shifting customer or threat needs.

For instance, when a new sensor requirement arises, it triggers a chain of activities: from defining the requirements and conducting systems architecture analysis, to design, supplier coordination, testing and building new manufacturing plans. Without a mature digital thread, these steps are often manual and time-consuming, resulting in delays and inefficiencies. A true digital thread enables seamless, automated data flow across all departments and processes, allowing teams to pass information effortlessly and automating both mundane tasks, like generating supplier specifications and complex tasks such as manufacturing plans. This level of digital maturity lets employees respond quickly to changes and ensures that the company can adapt without unnecessary delays. By creating a mature digital thread, companies can automate more processes and eliminate inefficiencies caused by manual data handling.

Aerospace digital twin

Another way to move beyond the “connect” stage is by leveraging the comprehensive digital twin. The digital twin is a precise virtual representation of a physical product or process. It is used across its lifecycle to simulate, predict and optimize the product and production system. For example, a digital twin of an aircraft enables engineers to predict how it will perform in various conditions and to test different configurations, like integrating a new sensor, without having to physically modify the aircraft. Simultaneously, a digital twin of the production process allows teams to simulate how a factory will operate, identifying bottlenecks or inefficiencies before the first product rolls off the assembly line. Once the product is in operation, real-time feedback from both the physical aircraft and the factory can be fed back into the digital twin, creating continuous optimization.

Artificial intelligence in aerospace

Artificial intelligence is another critical piece of helping you mature your digital transformation. However, AI adoption in aerospace remains low, with only 8 percent of companies using AI in technical workflows, according to the Siemens’ sponsored survey across Aviation Week network. Two of the leading reasons A&D companies are slow to adopt AI are related to trust. Some respondents claimed they can’t trust AI with their data, while others shared that they can’t trust AI with their results.

While some may have concerns about connected workflows and data security, advanced AI models like retrieval-augmented generation (RAG) offer a solution. This model allows companies to leverage public AI capabilities while protecting their proprietary data, ensuring that sensitive information is not shared or misused.

For aerospace companies, AI will enable them to train large language models on their own specific engineering and manufacturing data, creating “industrial-grade AI” tailored to their unique needs.

Siemens industrial-grade AI is trusted and physics based, which is critical for LLM-based gen AI and for all other types of AI. Siemens has been doing AI research and investing in AI for many decades and is continuing to work on solutions that support the future of AI in A&D. Here are a few examples:

*Note: As of September 2024, the shipping versions of these generative tools use AI, but they are not currently LLM based.

These AI powered tools are helping design and build complex products, like aircraft, by integrating company-specific knowledge and best practices, allowing aerospace companies to innovate faster and streamline production. AI is the key to unlocking the next level of efficiency and capability in aerospace, where data-driven decisions and intelligent automation will define the industry’s future. In addition to this, there are more ways to continue advancing digital transformation maturity.

Immersive engineering is a critical step on the path to digital transformation maturity for A&D companies, as it enables engineers to design 3D objects in a fully immersive 3D environment, rather than relying on traditional 2D methods. This approach is not only physics-based but also highly collaborative, allowing teams to interact with the design in a virtual space as though they were physically inside it. By stepping into the 3D world of mechanical design, engineers can visualize, test and refine complex systems more effectively. Immersive engineering also fosters collaboration across different teams, breaking down traditional silos and helping companies address key challenges related to cost, workforce efficiency and time-to-market. This enhanced collaboration and more accurate design process are vital for aerospace companies striving to achieve a higher return on investment and move beyond basic digital connectivity towards true digital transformation maturity.

Developing a clear vision for aerospace company’s digital transformation maturity

One of the biggest barriers to successful digital transformation is the lack of a clear vision and strategy. Many companies enter the digital transformation process without fully understanding what they hope to achieve or how they will measure success. This lack of vision can lead to frustration and stalled progress, as companies focus on short-term goals rather than long-term transformation.

Strong leadership is essential for overcoming these challenges. Companies must clearly define their digital transformation goals and ensure that all stakeholders are aligned on the strategy. Without this unified vision, digital transformation efforts can quickly lose momentum and companies risk missing the significant benefits that digital technologies can offer.

The Siemens’ sponsored survey with Aviation Week network highlights the importance of digital transformation in the industry, but it also highlights the significant challenges companies face in fully realizing its potential. Siemens’ five-step framework offers a roadmap for companies to assess their digital maturity and take the necessary steps to advance their transformation journey to avoid getting stuck in the “connect” phase.

By moving beyond the “connect” phase and embracing technologies like digital threads, AI, digital twins and immersive engineering, aerospace companies can unlock the full benefits of digital transformation.

For more information on these topics, visit these webpages below:

- Climbing out of the Digital Transformation Desert (Todd Tuthill’s slides)

- Developing a Clear Vision for Digital Transformation Maturity (Todd Tuthill’s slides)

Digital transformation maturity

- Solving workforce issues with digital transformation from Aerospace Manufacturing and Design Magazine

- The steps aerospace companies can take towards digital transformation maturity from Aerospace Testing Magazine

- New Technology Will Fill The Labor Gap – from Aviation Week Network

- Talking Aerospace Today Podcast (^Digital transformation maturity content for the Talking Aerospace Today Podcast begins in July 2023)

Artificial intelligence

- Generative design in aerospace from Aerospace Manufacturing and Design Magazine

- Why aerospace needs artificial intelligence from Engineering.com

- Bringing Aerospace Engineering into the Future with AI from Engnineering.com

Immersive engineering

- Accelerating digital transformation from Aerospace Manufacturing Magazine

Comprehensive digital twin and digital threads

Digital threads for aerospace and defense