The Siemens Vision for Convergent Modeling – Proof Point: Materialise

You may have recently seen that our partner, Materialise, announced that they will be adopting Siemens’ Parasolid modeling kernel in their upcoming Magics 26 release. Materialise and Siemens have been partnering to bring the best software capabilities to the additive manufacturing market for years, and this is one more step in that partnership.

There is an emerging recognition that additive manufacturing has outgrown the capabilities of “facet” or “mesh” modeling where the designer manipulates faceted bodies, facet by facet, to change a shape. And while the facet data type, such as that which is used in STL files, is not going away, there is a need for tools that allow for more robust and exact geometry manipulation.

This is where Siemens’ Parasolid comes in. Parasolid is the underlying modeling engine within Siemens’ 3D modeling software solutions like NX and Solid Edge, but also the underlying kernel for many other systems in the AM space, such as those from Altair, Elise, and now Materialise. Parasolid allows designers to manipulate solid geometry using “boundary representation “, or “B-rep”, models that allow for the exacting precision and easy geometry manipulation expected from a world-class CAD system.

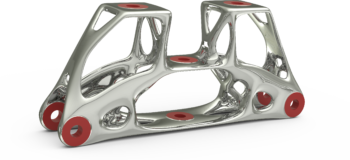

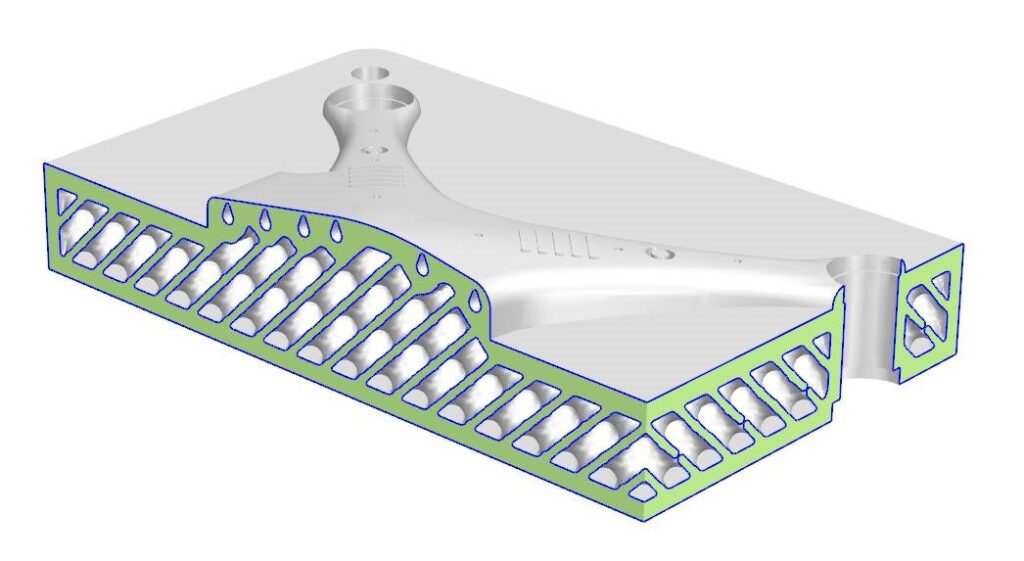

However, Parasolid also allows for the manipulation of mesh data, such as that found within STL files. Within Parasolid these two geometry types can be used and combined together. This brings designers the best of both worlds – The mesh bodies that many additive manufacturing tools expect and understand, with the precision and ease of use from modeling with b-rep models.

A b-rep exact surface mold with integral mesh gyroid lattice and conformal cooling channels.

Siemens was first-to-market with this hybrid mesh/b-rep modeling solution that we call “Convergent Modeling Technology”. Materialise adopting Parasolid is one more confirmation that our vision for a future where designers are free to design without regard for data type is not just desirable, but necessary to drive additive manufacturing forward.

The good news is that capabilities that go way beyond the base functions in Parasolid have been inside our NX CAD solution since 2016 and have been proven again and again by successful companies around the world. For example, with Convergent Modeling Technology within NX, designers can use Boolean operations (Unite, Subtract, Intersect, etc.) between facet bodies and b-rep bodies. This core Convergent functionality in Parasolid is enhanced with further tools inside NX such as 3D textures and morphing.

Hybrid mesh/b-rep modeling is not a new concept. However, it is a concept that has found a key purpose in additive manufacturing, and Siemens is the company who brought it to the world.

Find more information about Parasolid here: https://www.plm.automation.siemens.com/global/en/products/plm-components/parasolid.html

Find more information about Convergent Modeling technology here: https://www.plm.automation.siemens.com/global/en/products/mechanical-design/modeling-technology-platform.html

Find more information about additive manufacturing software from Siemens here: https://www.siemens.com/additive