Oakland University offers Industrial Engineering students hands-on, real world learning with Siemens Digital Industries Software

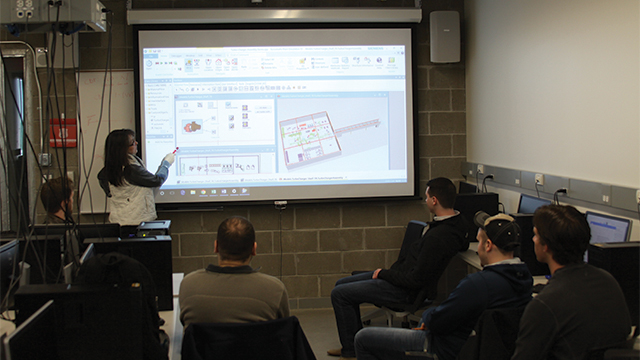

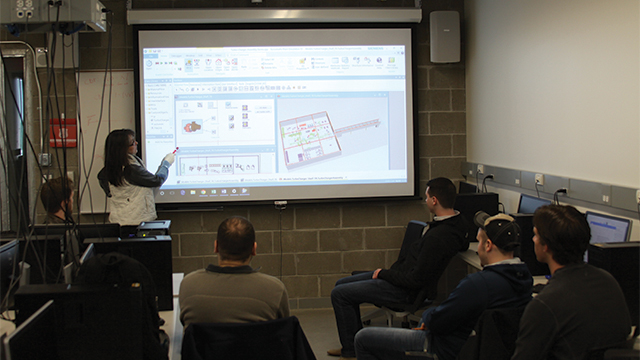

Oakland University’s Industrial and Systems Engineering department (ISE) joined Siemen’s global academic partner program in 2009, through the program the department received the Tecnomatix® portfolio of digital manufacturing solutions (including the Plant Simulation solution, Jack™ software and the Process Simulate solution) and Teamcenter™ software tools, as well as training and support. These were perfect for the department, who’s theme is product lifecycle management (PLM), and were integrated into several existing courses after the university joined the program.

“The use of Jack in the classroom allows our students to visualize ergonomic issues in another dimension. The students not only see how the worker fits in the customized workspace, but simultaneously can compare timing and throughput information while minimizing risk factors like low back injury and unsafe joint postures. Gaining hands-on experience using the Siemens PLM Software solutions has made our students desirable to many companies. Several of our ISE students have found positions working in digital human modeling even prior to graduation.”

Dr. Megan Conrad, assistant professor of industrial and systems engineering.

The ISE department is working on bridging the gap between the industry’s need for engineers who are highly skilled when entering the workplace, and students who want engineering to be their career path. “Our program is all about educating engineers for a lifetime,” said Robert Van Til, Ph.D., the school’s Chair and Pawley Professor of Lean Studies, Industrial & Systems Engineering Department. “It’s not about training someone to be super productive one day on the job. We are preparing engineers to be work ready right out of college.”

Oakland University is preparing their current students for Industry 4.0, but they know that recruiting and engaging engineers needs to start early. A STEM outreach program has been developed that has ISE students and faculty interact with k-12 students and teachers in a program that provides hands-on learning in a university setting. During this program, students use data they collect and run a digital simulation of an ATV factory using Plant Simulation. They also are given a short introduction to ergonomics and then use the Jack software program to run ergonomics simulations. The use of Siemens software is vital to this program and their intended goal of helping students interested in engineering learn real world skills.

Recent graduate John Katona has already seen the career benefits of using Siemen’s software during his time in the ISE program, “As a student, I used Plant Simulation to create a computer simulation to study the flow of patients in a local hospital’s emergency room. A company learning about my project on LinkedIn cold-called me for an interview, and they gave me a job offer the same day in their simulation group.”

To read about the ISE Program and the University in greater detail, click here. To hear an Oakland ISE student’s firsthand experience with the program, click here.