Formula Student China 2020 – Siemens Trains Future Leaders of Automotive Industry

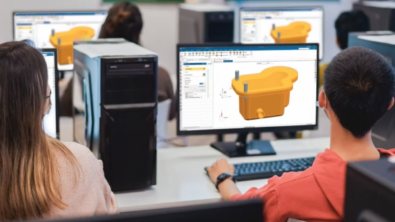

Formula Student teams at FSC benefited from on-site workshops on many technical engineering topics in the Siemens booth.

Co-authored by Jiajun Kang & Jianmiao Xu

As Siemens interns and graduate students, it was our great honor to participate in the 2020 Formula Student China event (Including Formula Student Combustion, Formula Student Electric, and Formula Student Autonomous classes). Siemens Digital Industries Software co-sponsored the event along with major industry companies.

Due to the pandemic of COVID-19, Formula Student events in many countries were cancelled in 2020. However, due to effective efforts to control the epidemic in China, the 2020 FSC event was successfully held in Xiangyang, Hubei province. Over six days from November 9th to 14th, a total of 170 university-level SAE Formula Student racing teams competed in various challenges such as technical design presentations and racing on the tarmac. There were 67 Formula Electric teams, a record 30 Formula Autonomous teams, as well as 67 Formula Combustion teams.

At the end, Jilin University won the championship of combustion class, Tongji University won the electric racecar class and Beijing Institute of Technology won first place in the extremely challenging autonomous racecar class.

As Siemens sponsor representatives, we would like to share some impressions about 2020 FSC. First of all, compared with their performance in last year’s event, many teams have made significant progress in both theoretical level and technical implementation level. Especially in the autonomous car class, the number of cars that passed technical inspection doubled versus last year. Three autonomous teams finished all the dynamic events on track versus none last year. For electric and combustion classes, more and more teams used new technologies, such as new engines, innovative motor control algorithms and more complex carbon fiber composite structures. These technological innovations have further improved the technical level and car performance of the Chinese student formula racing teams. If everything goes well, we are looking forward to the performance improvement of the Chinese student formula racing teams in international FSAE competitions. The ‘Digital Twin’ design methodology is really taking hold in FSC teams, with advanced software donations and training from Siemens.

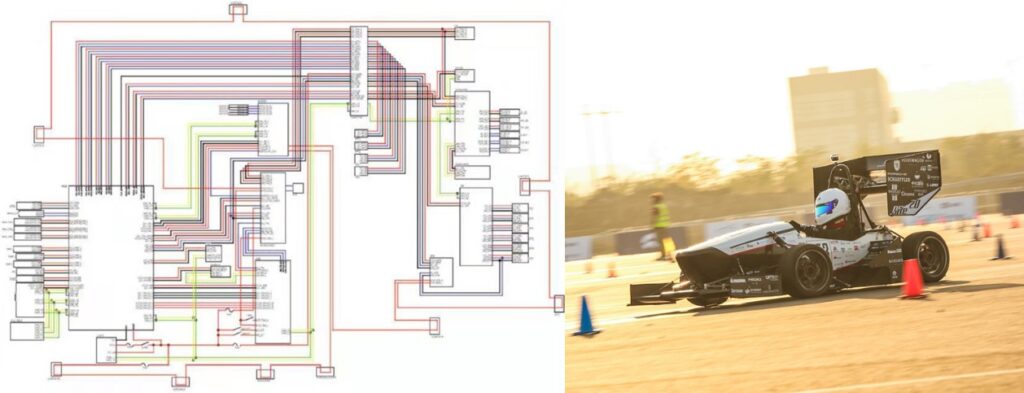

Another exciting improvement is that more and more teams are using advanced simulation and optimization technology to speed up their design process and improve their design. Among them, Tongji University electric racing team applied Siemens’ Capital & VeSys software to design their electrical wiring harness, and won this year’s Siemens “Siemens Award for Excellence in Electrical System & Wire-Harness Design”.

Jilin University took second place of the Award, and Harbin Institute of Technology(Weihai) won third place of the Award.

The Siemens academic team has carefully selected the software solutions that fit FS teams needs – from the extensive Xcelerator portfolio of technical software. For example, many team members asked our engineers for tips on using PADS Professional software and HyperLynx software to design, then simulate and verify their PCB (printed circuit board) designs. For example, some racing teams have designed their own electronic throttle controllers in the past few years. They want to use PADS Professional’s powerful features to speed up their PCB design iterations and correct-by-design auto-router. In addition, they are interested in the simulation feature of HyperLynx, to solve the reliability and stability problems in their PCBs – to help the boards last through the rigorous Endurance runs on the tarmac despite extreme electrical current, vibration and heat.

Student teams are also advancing in the application of 3D CFD tools like STAR-CCM+ to optimize aerodynamic wings. Alongside the NX suite of CAD/CAM/CAE tools, Simcenter STAR-CCM+ CFD software has become the de facto standard tool for the simulation and analysis of aerodynamic packages and cooling systems for Formula Student worldwide – as well as in major professional Formula One teams. The wings generate downforce but teams want to avoid too much drag. They can find the ideal solution to increase their racecar cornering speed while avoiding any significant reduction of straightaway speed.

For the wings, carbon fiber is used for light weight and strength. Siemens’ Fibersim composites design software uniquely is able to simulate the fabrication step, which can save cost-conscious student teams substantial amount of carbon material costs and labor. Fibersim helps get it right the first time by predicting fabrication problems before fabrication. With Fibersim bringing costs down, we will see more and more carbon monocoque chassis at FSC in the future, instead of much heavier steel tubing frames.

(‘The Mentor – A Siemens Company’ brand is replaced with the Siemens brand in 2021)

Nowadays, autonomous driving technology is developing rapidly, and many universities have set up autonomous car racing teams. Therefore, students are also interested in the autonomous driving technology and the simulation environment, such as Siemens’ Simcenter PreScan. In our workshops at FSC, they learned about PreScan’s powerful capabilities in driverless algorithm development and technology validation. Many students showed great interest in this software.

At present, the research level of autonomous driving technology in many Chinese colleges and student racing team are in the primary stage, and a powerful development and simulation tool is urgently needed to speed up their research process. We believe that PreScan can meet their needs well.

Although the Chinese student formula teams have made great progress in technology, but there is still a lot of room for improvement in the overall level of Chinese formula student cars’ performance. Moreover, there is a quite large range in sophistication between the top teams and the rest of teams. Especially in terms of academic knowledge and advanced racecar theory, design and fabrication, the performance of students from top universities and ordinary colleges is very obvious. This can be seen from the final score of each team in the design report competition and the judge’s post-competition evaluation. We believe that Chinese students need more opportunities to share and apply advanced automotive technology, and strengthen their learning and understanding of how to academic knowledge to real-world competitions like FSC. In this way, they can further integrate the existing technical resources and make more innovative achievements.

Finally, we can see that the FSC event has gained more and more attention and support in China. The government, universities and industry have acknowledged the great significance of the event for improving the real-world engineering know-how of college students. With the graduation of students who have FSAE experience and entering various automobile or related companies, we are certain they will make greater contributions to the automobile industry. Many Chinese automobile companies and their supplier manufacturers give priority to students with FSAE experience.

They recognize that FSAE competition greatly improves college students’ academic level, engineering literacy and practical ability. In recent years, more and more enterprises and universities increased support for FSAE projects to enhance their influence in the automobile industry or improve the overall ability of mechanical engineering graduates.

Thank you for reading our thoughts on FSC 2020 as interns of Siemens. It should be pointed out that China’s automobile industry is undergoing a challenging transformation process including electrification and autonomous driving support. To support this industrial technology upgrade, a large number of new engineers with solid foundation and innovative spirit are needed.

The FSC competition cultivates students’ real-world engineering literacy and prepares them for the challenges in their future careers. Siemens will continue to sponsor the event, the teams, and educate future engineers in FSC competitions. We are confident that our Global Academic Partner Program will better help these future engineers grow and contribute to society.

[End]