Engineering.com: How custom machine shops live with industry’s large volume obsession

Schuster Mechanical’s secret to success

Zel X user Bob Schuster was recently interviewed by Engineering.com to share his machine shop’s secret to success. His success is as simple as “cater to the big guys”. As a small but powerful machine shop, it’s Schuster’s skills, flexibility and adaptability that separates his business from the rest. If customers call him to a production facility to help design a tool, replace a broken part or make minor changes to a line, he shows up when needed. “After all, you can’t stop production,” he says. “I will see the existing design and propose a new one.”

Bob Schuster of Schuster Mechanical is no stranger to the automotive industry. As a GM veteran, his passion for the part manufacturing industry grew into the business he built today: Schuster Mechanical LLC. Though already a manufacturing expert, Bob quickly trained up on Siemens technology, acquired CNC equipment — and Schuster Mechanical LLC was born. His success in the automotive field, and now adjacent industries, continues to this day.

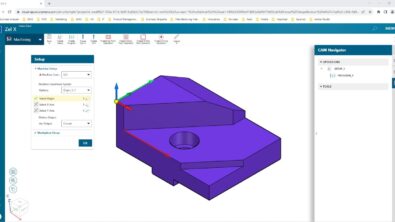

Improving machine shop efficiency with Siemens technology

Schuster mostly makes new grippers or effectors and installs them to legacy equipment. These parts must be custom designed to grab, mount and move parts during manufacturing and assembly.

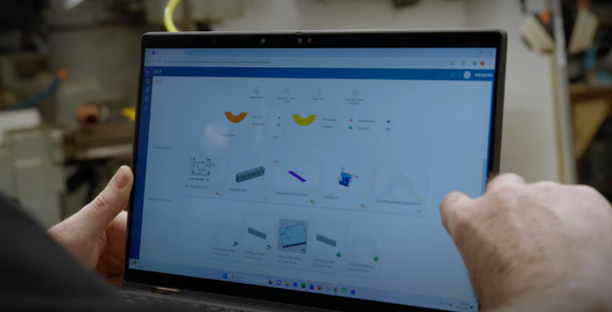

As an early adopter of Zel X software, Bob witnessed firsthand the power of cloud-based management solutions. It helped him to capture the manufacturing process, communicate with clients, capture drawings, and reuse the job data from repeatable jobs with his customers. With its intuitive interface and robust features, Zel X Shop Operations. maximized how Schuster operated, freeing him to focus on what truly mattered – the CAD and CAM work to machine high-quality parts.

“My job is to build the fixture and it’s important for me to design it properly and deliver it on time,” he says. This accuracy and time sensitivity is key. If the part is not ready on time, then it may not be available for installation during a plant’s scheduled maintenance.

Read the full story by Engineering.com to get a glimpse into the power of digitalization →

Learn more about Zel X

Learn more about Zel X, click here.

Ready to try Zel X? Click here for a free 30-day trial.

Join the conversation

There are a lot of ways to hear what others are saying and to connect with other Zel X enthusiasts online.

Here are a few ways to join the conversation right now:

- Keep up with #ZelX on Facebook, YouTube and LinkedIn

- Join our online Zel X Community to connect with other Zel X users