Using a comprehensive digital twin to optimize sustainability

Product design has always been a balance of performance, cost, quality and meeting the needs of the market. Only recently have companies started adding one more factor to their innovation: sustainability.

Sustainability asks, What is the full, lifetime environmental impact of a product?

Eighty percent of product’s environmental impact is determined in the development and design phase where decisions are made about which materials are used and what they’re made of, how the product is manufactured, energy efficiency including carbon footprint and resource consumption, and what happens to it after its usefulness ends. These decisions also restrict what design and manufacturing choices are available later in development.

Sustainability must also go beyond what the individual company does though and account for the suppliers, distributors, and logistics providers as well.

The earlier in the process decisions are made, the more sustainable and cost-effective the product and process for creating it can be.

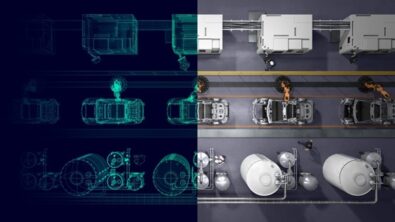

Data and digitalization are the foundation for creating this holistic approach to design. Companies can build on a digital twin to simulate, verify and validate products throughout the entire process.

A look at sustainability in the marine industry

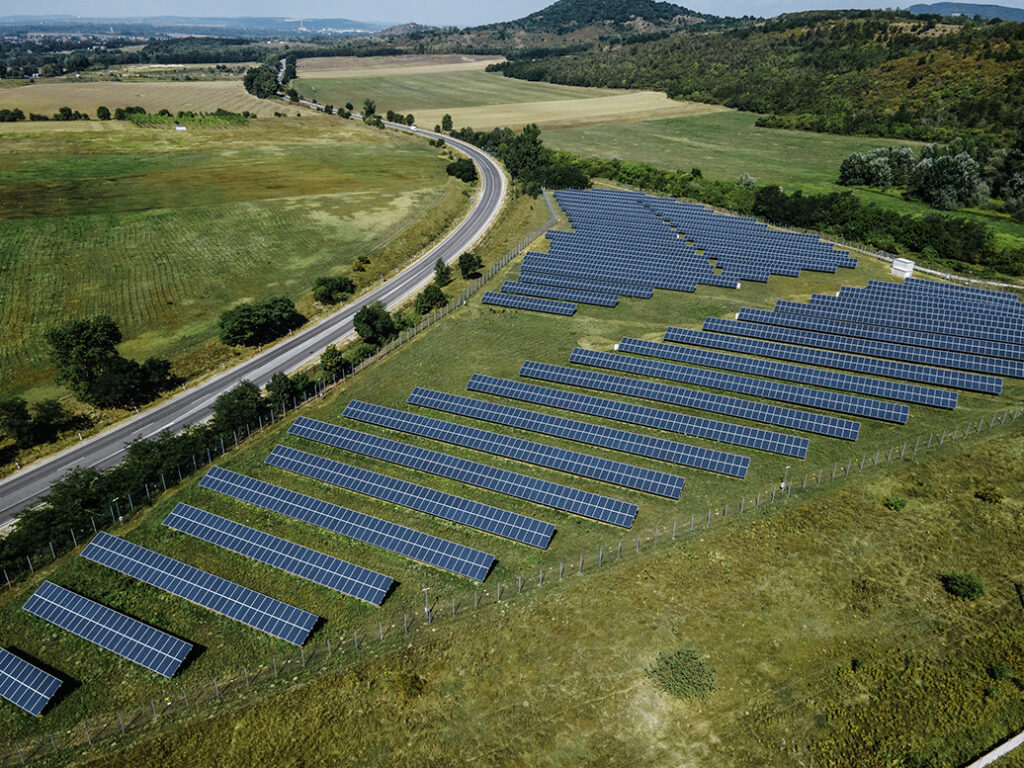

The transportation industries have a major impact on the environment. Whether it’s marine, automotive or aerospace, the trend continues toward greater sustainability and reducing their carbon footprint. This is quite visible as countries and localities implement new laws and regulations designed to increase vehicle electrification and reduce emissions.

The marine industry is less visible yet 90 percent of the world’s trade involves shipping. While shipping is considered the most efficient form of commercial transport, its sheer volume equates to a monumental impact on the environment including noise pollution, oil spillage and greenhouse gas emissions. Even the smallest watercraft can have a negative impact on the local environment. But that does not have to be the standard.

Take a look at Cox Marine, a company embracing a system of systems design approach for sustainability improvements. Digitalization has helped them realize a 25 percent more fuel-efficient motor design that stays in operation three times longer than their previous generation. Another example is the much larger engines from Wärtsilä, one of the world’s largest ship engine manufacturers. They created the most fuel-efficient diesel engines used in large shipping vessels while reducing their physical testing and increasing their virtual testing.

Using digitalization to achieve sustainability

Today’s products are likely not a single system, but rather many systems of systems requiring multiple engineering disciplines for successful development. Using Cox Marine as an example, their outboard motor design is complex featuring over 6,500 part numbers that engineers working in a variety of domains must be able to access in a reliable digital environment.

To innovate tomorrow’s sustainable products, it’s imperative that the right digital tools are available.

Robust simulation capability is the perfect example of digital tools that designers and engineers can use to test and verify as early and often as possible. They can optimize individual systems and balance how the diverse domains interact as well as the production process.

By assessing sustainability requirements from the beginning, the engineering teams can make faster, better-informed decisions early on. Assessing the sustainability, cost, performance, and quality of a product and production early in development offers an intelligently defined design space where factors like material selection can be determined in order to reduce emissions in everything from extracting it from the source to usage in the product to waste of excess material.

To accomplish this, the first step is to enable the comprehensive digital twin of the product and extend into production for the most complete understanding. This will help define how the product is produced, its logistics costs, its usable lifetime, and how it fits into a circular economy through reuse or recycling.

Regarding sustainability decisions in the design phase, accessing the most accurate and broad collection of data to create a truly comprehensive digital twin will enhance a company’s flexibility, lower costs and increase competitiveness.

Building the comprehensive digital twin with data

Holistic sustainability indicators must be integrated into the digital twin of the product from the beginning. The design can be built to include both physical sensors that collect diagnostic and environmental conditions of a product through manufacturing, delivery, and usage and virtual sensors that can rely on the models created in the digital twin to provide more information. On top of that, business data can offer insights into sustainability like carbon footprints, emissions and material costs.

The physical sensors can continually feed updated data into the simulation models, providing a clearer understanding of the impact of decisions while virtual sensors employ data from physical understanding and models enabling closed-loop optimization between design, manufacturing, and performance.

The challenge of processing this amount of continuous data can be resolved through artificial intelligence (AI) and machine learning. AI can help detect issues early on as data is brought back into the digital twin by comparing data to expected results from simulation. Once the cause of the issue is determined, an over-the-air update can be pushed to the product or, if it’s a hardware issue, the data can be shared with the organization and supplier network to correct the problem.

Building for sustainability

The industrial world is facing a major challenge: innovating with finite resources and doing more with less.

Sustainability is about designing, realizing and optimizing a product across the entire value chain. It enables a product to be delivered with the fewest number of resources. This requires a system of systems approach to creating a comprehensive digital twin and establishing the digital environment for simulation. Just as important is the ability to take in data in real time from the physical prototype or product as well as sensors on the manufacturing floor that is used to optimize the product and production.

Digitalization and automation provide an infinite amount of data, facilitating a comprehensive digital twin that combines the real and the digital worlds, and ensuring companies have the tools to use finite resources efficiently.

Siemens Xcelerator is our easy, flexible, and open digital business platform that helps our customers innovate faster and become a competitive Digital Enterprise. With a comprehensive digital twin, companies have the capabilities to combine the real and digital worlds enabling integration of the product, production and performance data resulting in continuous optimization.

Imagine using data to examine countless “what if” scenarios and predicting future performance with the Digital Twin. This leads to understanding the full, lifetime environmental impact of a product and therefore an ability to create superior and more sustainable products.

Let’s dream of a better world. And make it.

Learn more about our Siemens Xcelerator software for industry and discover how you can turn complexity into your competitive advantage.