How digital are industrial machinery companies?

Industrial machinery continues to grow in complexity, requiring integration of multiple domains including mechanical, electrical, electronic and software design. This trend is set to continue as demands for integrated AI and vision systems, machine connectivity and remote monitoring increase. Considering the simultaneous pressure to shorten delivery times, machine builders face a huge challenge.

To address this challenge, the most progressive companies are increasing their adoption of digital technology to accelerate innovation and optimize existing products. The recently produced 2022 Digital Twin Study by Lifecycle Insights found that the most progressive companies will continue to invest in technology, increasing the gap with those who lag, leaving them subject to a harder competitive outlook and potential losses in time to market, and ultimately lost business.

What does this mean for those they’re supplying machines to? In general, the more progressive companies can better collaborate with their customers and assure on-time delivery and achieve target costs. During the bidding process, the ability to supply richer information earlier in the process allows their customers to plan and integrate new machinery into their production systems – further shortening the installation and commissioning times and therefore improving time to value.

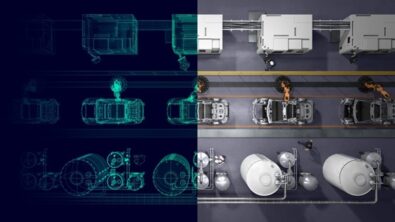

The adoption of a digital twin strategy allows machine builders to demonstrate and prove machine capabilities before any physical machinery is built, supporting discussions around alternate concepts at an early stage – which gives customers confidence in their ability to deliver the best solution. The digital twin approach combines the real and digital worlds, breaking down the silos between domains and enhancing efficiency and collaboration.

Industrial Machinery companies face unique challenges and opportunities. To shorten lead times, they must be proficient at understanding the entire systems – integrating their machinery with PLC’s, HMI’s and new technology such as AI and machine vision. Carrying out these activities in a ‘virtual commissioning’ environment allows them to make design changes early in the process when costs are much lower, validate that machinery operates as designed, and accelerate installation, test and commissioning.

With an expansive portfolio of software, services and development platform, Siemens is speeding up your digital transformation. This portfolio is an integral part of Siemens Xcelerator — a new, open digital business platform which makes your business more flexible, resilient, efficient, and sustainable. This includes Software as a Service, or SaaS, options giving companies unprecedented access to the cloud and is scalable and flexible to meet your specific business needs.

Learn more about our Siemens Xcelerator software offering.

Read the full 2022 Digital Twin Report here.