Meeting the 5G physical design and verification challenges with Siemens EDA

The massive buildout for 5G communications is just getting underway. The technological and economic impact is expected to be massive. To reach maximum 5G capability will require engineers and design teams to create ever-more advanced edge devices and infrastructure equipment. That process will start with innovating a new generation of integrated circuits (ICs).

Meeting the 5G IC physical design and verification challenges with Siemens EDA solutions via the Xcelerator portfolio can provide higher levels of success in developing 5G technologies, enable new businesses and business opportunities and broaden 5G adoption.

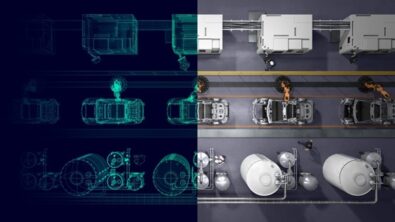

5G physical design and verification

One of the fundamental demands of any 5G system, whether it be for 5G infrastructure or 5G edge devices is to optimize for the best performance per watt (PPW). The System of Chip’s (SoC) designed for 5G infrastructure need to be extremely high-performance to receive, interpret and then transmit data as fast as possible.

One significant challenge is the amount of energy the 5G infrastructure equipment will consume: estimates are upwards of 50 to 68 percent more energy than 4G equipment. Meanwhile, telecommunication companies are trying to reduce energy footprints without sacrificing performance requirements.

By using the industry’s most modern and advanced physical design technology companies can meet these challenges of physical implementation of SoC design, which will lead to achievement in optimal performance, power and area (PPA) for all applications. Siemens EDA is helping future-focused design teams reach optimal levels of PPA faster and optimize designs for best performance per watt.

Siemens EDA benefits physical design teams by providing the technology and tools for:

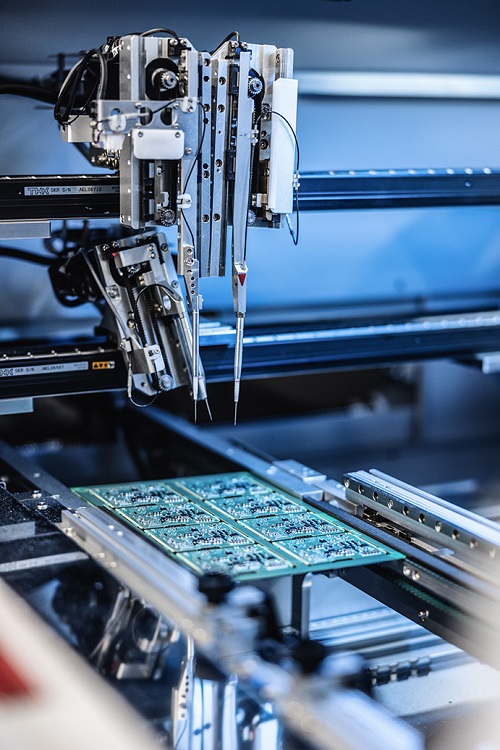

- Custom digital and analog IC design to develop high-speed I/O or any custom digital and analog chips and chiplets (for 3D IC) for 5G implementation.

- Power integrity analysis since a majority of 5G SoCs are a mix of digital, high-speed analog IO and mixed-signal IP blocks. Siemens EDA’s power integrity solution can perform highly accurate EM/IR analysis across the entire IC.

- Parasitic extraction because 5G ICs require a mix of leading-edge performance, low power and the highest degrees of reliability. Design teams must create an accurate analog model of the parasitic effects of the structures and wires connecting those design elements so they can then perform exhaustive timing, power, circuit and signal integrity analysis of the design before moving it to verification and manufacturing.

- Physical verification to ensure 5G designs will be signed off faster and ready for manufacturing sooner.

Ready to learn more about how Siemens EDA is playing a role in helping companies accomplish 5G physical design and verification challenges?

Download How Siemens EDA helps you engineer smarter 5G communications systems faster.

Discover how Siemens Xcelerator helps companies design, engineer and manufacture a better future.

Siemens Xcelerator also offers Software as a Service as part of its comprehensive portfolio and can help companies designing 5G technology create their products via unprecedented access to the cloud. Learn more about this scalable and flexible way to meet your specific business needs.