Where DX efforts are providing the most value

Digital transformation (DX) initiatives are spreading across industries, with a strong presence in product development and manufacturing. This raises two important questions: Where are companies making DX investments, and what progress have they made? The experience of the most progressive organizations shine a light on where DX efforts can provide the most value.

Lessons Learned from Progressive Organizations

To better understand how, when, and where product development and manufacturing organizations are leveraging DX initiatives, Lifecycle Insights conducted two research projects: the 2021 Return on Investment (ROI) of DX Study and the 2022 Digital Twin Study. The first survey compared organizations based on their current pursuit of DX initiatives. The latter study took a deeper dive, measuring the maturity of digital twin and digital thread use across different manufacturing organizations, as well as how well those companies were able to integrate the two virtual models.

Lifecycle Insights used consistent methodology to stratify respondents into least progressive, moderately progressive, and most progressive organizations. In our initial report, we learned respondents from the most progressive companies pursued 12.5 investment initiatives compared to the least progressive group’s 3.5 in the least progressive group. More importantly, these investments paid off. Fully 10 percent more of the most progressive organizations’ product development projects hit or exceeded their defined margin targets. The overwhelming takeaway from both studies is that organizations that make targeted investments in DX initiatives are able to translate those efforts into tangible improvements in organizational performance. For example, findings from the ROI of DX study showed that companies working on forty development projects of the highest complexity can save over $1.5M on mechanical prototypes and $2.7M on board respins. Such savings make a significant impact on development budgets.

Progressive Insights for Product Design

Lifecycle Insights’ ROI of DX Study provided interesting insights into how aggressively the most progressive organizations are pursuing innovative digital practices. In general, they adopted such initiatives at two to three times the rate of their least progressive counterparts. That rate was seen across a variety of different engineering domains, including mechanical, electrical, electronic, software, and systems design. The most progressive companies also built and leveraged digital twins to model and then run simulations on different aspects of their products to help optimize design. They used DX to build out richer types of design documentation so that other functional departments and company stakeholders could use it to support the rest of the product development lifecycle.

Lifecycle Insights’ Digital Twin Study dives deeper into the findings and provides more detail on how the most progressive companies are accomplishing such feats. Respondents reported relying on more standardized solutions to create more complete digital definitions of their products across different engineering domains. In addition, they leveraged more advanced solutions like product data management (PDM), product lifecycle management (PLM), and application lifecycle management (ALM) to centralize and manage various design-related assets and artifacts. This created a single, central digital location where all stakeholders could gain access to the design data they needed to do their work, optimizing organizational performance.

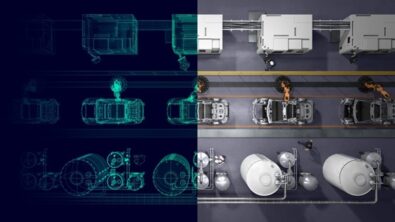

Progressive Insights for Product Manufacturing

The benefits of DX were not limited to product development. Respondents from the most progressive organizations said they also extended their efforts to production. In fact, both studies highlighted similar lessons about the use of DX initiatives after product design is complete. For example, Lifecycle Insights’ ROI of DX Study revealed the most progressive companies created digital representations of their manufacturing process at varying scales. These models spanned machining toolpaths, workcells, production lines, and even entire production facilities. The most progressive organizations were three to four times more likely to employ such practices, depending on the application, to support the development of more efficient production facilities.

The most progressive organizations also reported using simulation for a variety of different tasks, including safety verification and virtual commissioning. Again, the theme remained the same: digital work saves time and resources in the physical realm. Lifecycle Insights’ Digital Twin Study offered deeper insights into the context in which such digital tools were commonly used. Like their peers in product design, manufacturing engineers relied on more standardized solutions to create and manage their digital definitions. Interestingly, they also employed more standardized processes across the different phases of manufacturing planning. This allowed them to execute their manufacturing plan faster, ramping up to full production in less time with fewer hiccups.

Applying Progressive Lessons

Progressive organizations are leveraging a variety of different DX initiatives, including digital twins and digital threads, to help them optimize the product development and manufacturing lifecycle. Results from Lifecycle Insights’ ROI of DX and Digital Twin studies demonstrate that the most progressive organizations are utilizing digital tools from the very beginning of product development through manufacturing. As a result, they are realizing significant benefits in terms of both organizational and operational improvements. The lessons learned from these organizations should inspire other companies in the product development and manufacturing space to make their own DX investments—and to continue, if not ramp up, the DX efforts they’ve already begun.

Read the full Digital Twin Study here.

Discover how companies are using digital transformation to turn complexity into a competitive advantage. Click here.