Digital twin technology helps drones deliver life-saving supplies

More than two billion people worldwide lack adequate access to essential medical products, such as blood and vaccines. Challenging terrain and gaps in infrastructure are primarily to blame for this global deficiency in access to medical supplies. In Rwanda, the decidedly mountainous landscape and relatively limited road system make it very difficult to bring supplies to remote communities.

Recognizing this, Zipline International Inc. (Zipline) launched the world’s first drone medical supply delivery system in 2016, operating on a national scale in Rwanda to send urgent supplies to those in need seven days a week in any weather conditions. As Zipline designed and deployed their drones, they realized that digital transformation solutions were key to improving their drone designs and continuing their life-saving deliveries.

A life-or-death mission, transformed by technology

Through the use of drones, Zipline improves access to critical medical supplies by flying over impassable mountains and washed-out roads, delivering directly to remote clinics. The company centralizes supply and provides on-demand deliveries, dramatically reducing waste and stock outs. Zipline is responsible for the blood supply of the western half of Rwanda, and has made over 7,000 medical supply deliveries, supplying over 13,000 units of blood to blood-deficient hospitals. And last year, Bono, the U2 frontman and philanthropist, joined Zipline’s board of directors.

To receive the medical products they need, health workers at remote clinics and hospitals text their orders to Zipline. Those products are centrally stored at the Zipline Distribution Center, enabling immediate access to even the most sensitive or scarce items. These items are packaged at the distribution center and prepared for flight, maintaining the temperature-controlled supply chain and product integrity.

Within minutes of sending their text message, health workers receive confirmation that their order has launched. Traveling at speeds in excess of 100 kilometers (km) per hour (over 62 miles per hour) with an 80 km service radius (approximately 50 miles), products arrive fast, with no pilot required. In under 30 minutes, the medical products are delivered gently by parachute into a designated area the size of a few parking spaces. Hospital staff are notified of their arrival via text message.

Digital twin technology transforms drone design

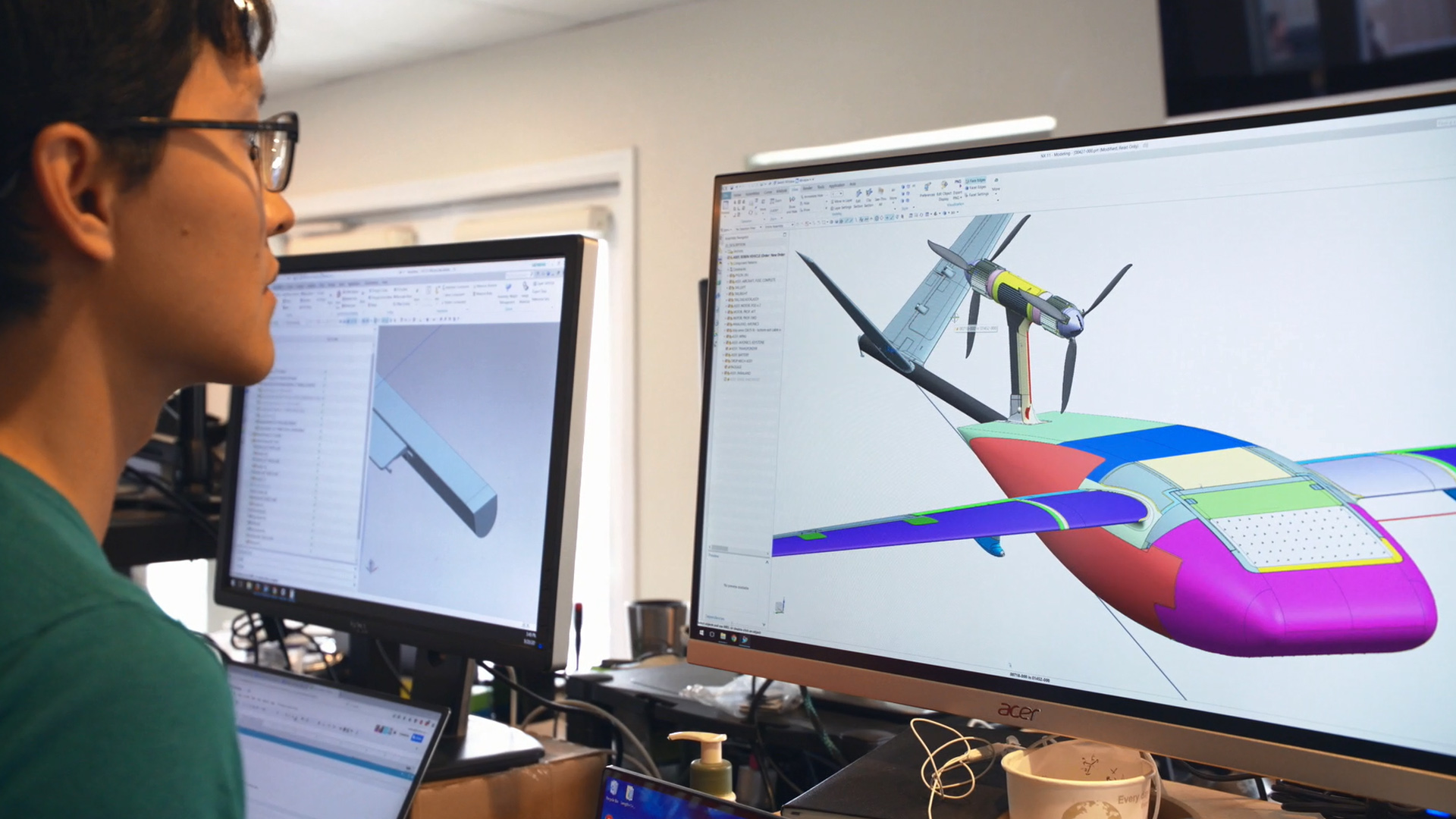

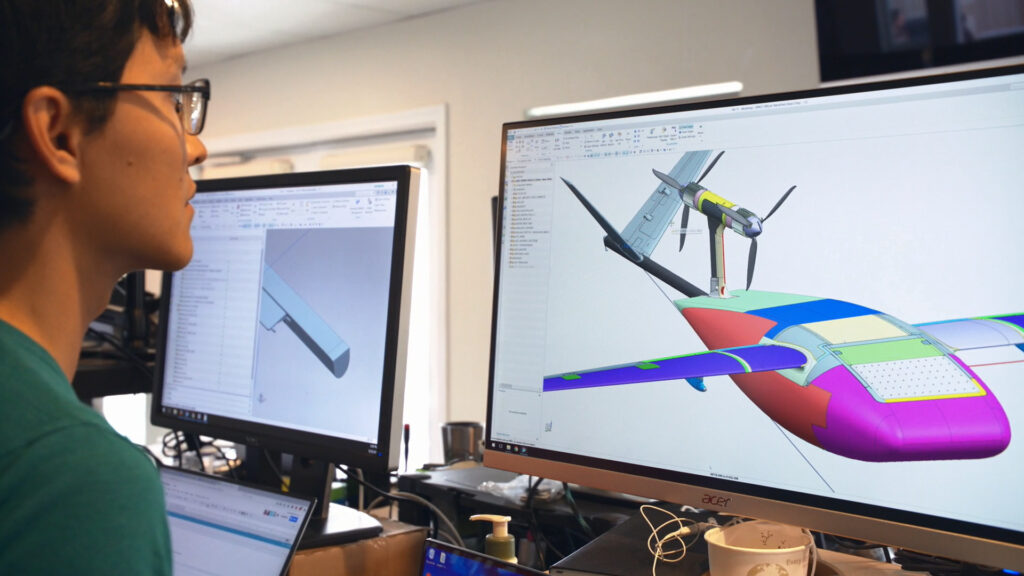

To design the drones, Zipline needed digital solutions that support robust digital twins of their product. Their previous CAD solution struggled to load models of the entire aircraft, discouraging engineers from performing certain critical tasks. The solution also did not support close collaboration between multiple engineers while designing the drones. These limitations dramatically slowed Zipline’s engineers while designing their lifesaving drones.

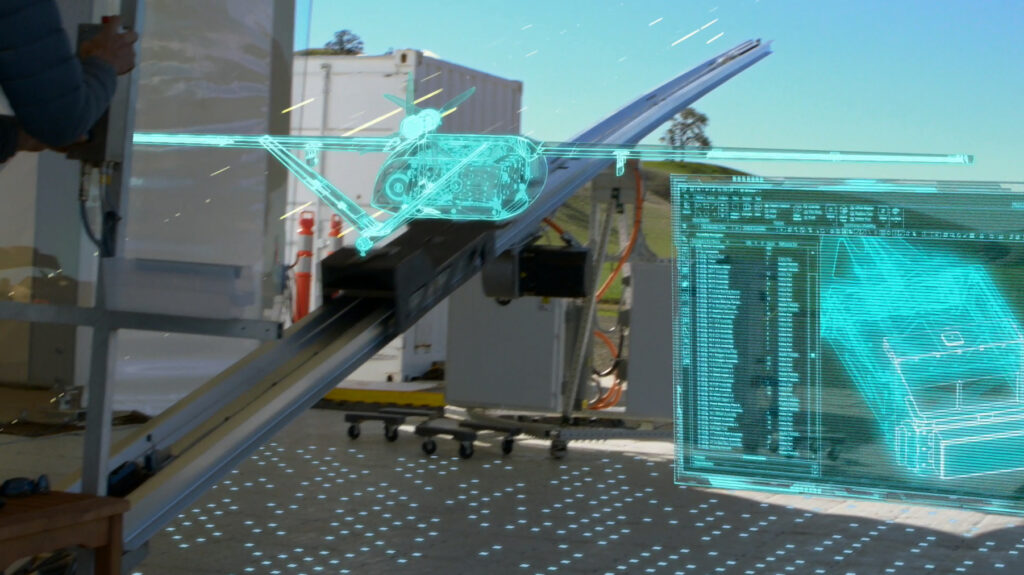

Zipline found that NX™ software from Siemens Digital Industries Software was the ideal solution for their drone designing needs. NX supports comprehensive digital twin technology, enabling Zipline’s engineers to load the entire aircraft, including its mechanical and electronic components, into the CAD model. Engineers can use this digital twin of the product to check the fit of individual parts against the rest of the plane, examine aerodynamics and more. NX also allows multiple engineers work on the same parts in real time, checking the fit and function of these parts in a live, collaborative environment. In sum, these capabilities help Zipline’s engineers continue to transform their drone technology.

“NX allowed us to create a shell for our entire vehicle and then work from the inside out as well as the outside in in order to develop it rapidly,” says Paul Perry, mechanical engineer, Zipline. “We also went from a team of three engineers to a team of nine. This is important because we need to have multiple people working in the vehicle at the same time. NX has allowed us to run a very robust master scheme using wave linking in order for us to take top level masters and drive those changes through multiple subsystems.”

NX, part of the Xcelerator portfolio, provided Zipline with a digital foundation to accelerate their drone design and validation activities, enabling digitally-driven product transformation. This allows Zipline’s engineers to work faster and smarter as they continue to refine the drones that carry life-saving medical supplies to remote communities. To learn more about Zipline’s work, watch our video. You can also learn more about the Xcelerator portfolio here.