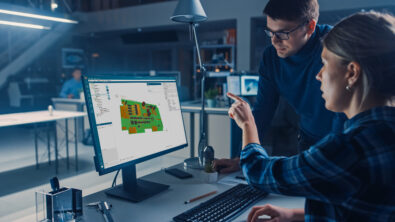

New eBook: Improving PCB Manufacturing with Smart Data

In this blog post, we will share an exclusive excerpt from our new eBook The Printed Circuit Assembler’s Guide to…™ Smart Data: Using Data to Improve Manufacturing. The book is the latest in the series “The Printed Circuit Assembler’s Guide to…” from I-Connect007, and I was very fortunate to work on it together with my colleague, Sagi Reuven.

Please enjoy this excerpt from the introduction and be sure to download the entire book here.

Introduction to The Printed Circuit Assembler’s Guide to…™ Smart Data: Using Data to Improve Manufacturing

Whenever we discuss data, keep in mind that people have been collecting data, verifying it, and translating it into reports for a long time. And if data is collected and processes are changed automatically, people still will be inter¬preting and verifying the accuracy of the data, creating reports, making recom¬mendations, solving problems, tweaking, improving, and innovating. What¬ever data collection system is used, any effort to digitalize needs to engage and empower the production team at the factory. Their role is to attend to the manufacturing process but also to act as the front line of communications and control.

When operations are not performing as expected, they need to be able to:

- Act as the first line of issue containment so that they can minimize the effect of the problem on the final product or process through problem-solving and corrective actions in real-time.

- Act as intelligence gatherers during escalation events when engineering is called to the work cell so that they can spend less of their time on data gathering and more on re-engineering for root-cause elimination to remove the possibility for any undesired condition to reappear.

To help your factory take the next steps in the journey to digitalization, in this book, we’re going to look at some of the major hurdles that your teams face in collecting manufacturing data that then will be useful—not only for improving processes but also for improving materials and supply chain management, tracing the sources of problems and defective or counterfeit parts, and providing trends analysis for business forecasting and reporting.

In Chapter 1, we will look at the challenges of collecting good data and where collecting it makes sense for the factory and improving business. In Chapter 2, we will examine what makes data smart, meaning the difference between data on its own and analytics. In Chapter 3, we will cover how data can be distributed from the underlying infrastructure for external use. We also detail some of the tools available today to help you put these principles into practice and look at a real-world example of how companies are reaping the benefits of putting their data to good use with analytics.

To read the full eBook, download it for free here>>