Design for ICT Testing: Driving Real Optimization in Electronics Manufacturing

Electronic Manufacturing Academy – Module 5 | December 18

At Goaltech’s Electronic Manufacturing Academy (EMA), we have created a learning environment dedicated to elevating the way engineers, test specialists, and production leaders approach their electronics manufacturing workflows. Each module is carefully designed to provide a practical, modern, and industry-aligned perspective, one that reflects the real challenges faced across today’s competitive manufacturing landscape.

Throughout the previous modules, we explored foundational and advanced topics, including SMT production programming, manual assembly best practices, and manufacturability rule validation across multi-brand and multi-platform ecosystems. We also examined strategies to balance and optimize workloads throughout the production line effectively. These discussions highlighted that achieving operational excellence requires not only state-of-the-art equipment but also integrated digital methodologies that unify data, reduce variability, and empower engineering teams.

Our upcoming Module 5, scheduled for December 18, is set to tackle a critical topic that often represents a significant bottleneck in electronics manufacturing: Design for Testing and ICT Programming.

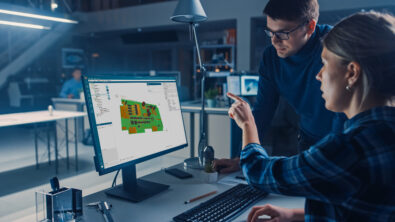

In-Circuit Test (ICT) remains a critical step in validating the quality and reliability of printed circuit boards. By performing automated electrical testing, ICT ensures proper component placement, verifies connectivity integrity, and detects common issues such as shorts, opens, missing or incorrect components, and soldering defects. This stage acts as a quality gateway, ensuring that assemblies meet rigorous standards before moving into subsequent production or testing phases.

Leveraging Process Preparation software, one of Siemens’ most powerful technologies for electronics manufacturing, engineers can generate ICT test programs for equipment such as Keysight, using a unified and intuitive interface. This centralized workflow significantly accelerates program development, minimizes manual errors, and enhances traceability. As a result, ICT engineers can focus on refining preparation times, driving continuous improvement, reducing failure rates, and ultimately lowering the total cost of electronics manufacturing.

At Goaltech, we believe that true manufacturing optimization emerges when advanced digital tools are paired with high-value technical education. Through the Electronic Manufacturing Academy, we reinforce our commitment to supporting companies as they transition toward smarter, more connected, and more efficient production environments. EMA is not only a training initiative, it is a platform for building capability, sharing industry best practices, and empowering teams to rethink what is possible in their manufacturing operations.

Ready to optimize your electronics manufacturing?

Join us for Module 5 on December 18 and continue advancing your knowledge, skills, and results in electronics manufacturing together with Goaltech and Siemens.