Software upgrade and migration strategies for electronics manufacturers

A new white paper by Mark Laing

Many electronics manufacturers struggle with outdated software, staying with it in part because SMT manufacturing machine software can be difficult to update. This can cause problems for IT staff and lead to inefficiencies, such as similar data preparation tasks being repeatedly performed by multiple people. Additionally, older software versions are often kept off networks to prevent security vulnerabilities. This all leads to workarounds on top of workarounds, creating an absurd situation in which “free” machine software increases overall costs.

Adopting the right strategy for handling software upgrades is vital to preventing these problems. Our new whitepaper details three important considerations to evaluate when making decisions about software updates and migrations.

IT infrastructure

Software security is based primarily on patches that software providers create every time a vulnerability is uncovered. To protect operating systems with the latest security patches, IT must make sure that all systems are up to date. But machine software can pose problems if it hasn’t been validated by the vendor for the latest version of Windows, or if it’s difficult to obtain driver updates that are compatible with aging hardware systems.

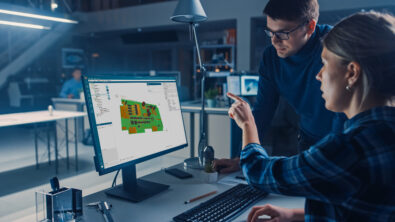

Personnel, productivity and process

The most significant gains in productivity are achieved when new solutions are combined with new processes. It’s important to look at a factory as an integrated ecosystem, not only upgrading software but also training people to utilize its capabilities. That’s why existing practices should be reviewed and optimized when software is updated.

Financial considerations

Current state-of-the-art solutions should be able to handle part and package data in a standard way and generate specific machine data on-demand. When they can’t, data inconsistencies and lack of interfaces with other machines or vendors lead to inefficient workarounds that increase costs. With the increasing prevalence of high-mix, lower-volume production in PSB assembly, the inefficiencies are becoming more costly – especially as batches grow in both size and number.

Widen the scope to mitigate software upgrade challenges

Electronics manufacturers should consider the entire production ecosystem when making decisions about software upgrades and migrations.

Modern manufacturing software tools such as Siemens’ Valor Process Preparation provide complete orchestration of lines, sites and multisite operations, helping to eliminate the consistency and reliability challenges posed by machine-specific software. Valor Process Preparation also provides a solution for part and package libraries, serving as a single source for part and package data and then transforming it into machine-specific data formats when needed.