Published article: Machinery benefits of a multi-disciplinary design

The current manufacturing landscape is witnessing exponential progress with sophisticated machines becoming mechanical geniuses. Also, in recent years, electronics is imparting a considerable contribution to several aspects of these machines, driven by advanced software controlled by PLCs and CNCs – a significant component to the overall equation.

In a recently published article in Industrial Machinery Digest, I cite how all the engineering disciplines must work closely together to ensure a design is completed on time and cost-effectively manufactured and commissioned. That is why machine manufacturers are leveraging a multi-disciplinary design approach to be more efficient.

Multi-disciplinary design

A multi-disciplinary design approach is combining all the capabilities and skillsets for advanced machine engineering into a concerted setting, resulting in machine design to achieve higher quality in a collaborative manner – all together – even with each discipline in separate areas.

As companies move towards a more collaborative approach, conventional processes still provide a level of value in the migration, proving that when companies in machinery and automation adopt new technologies, they should do so thoughtfully for innovations to be successful.

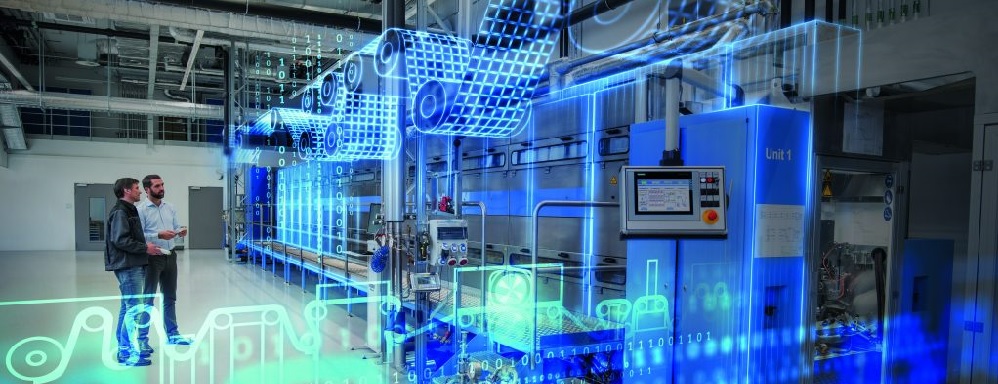

Machine builders are also relying on a comprehensive digital twin that represents everything that constitutes the machine: mechanical, electrical, hydraulic, fluid, pneumatics, design domains, performance, simulation, and automation code. To achieve truly multi-disciplinary design, companies need a fully integrated portfolio of software, services, and application development platform, personalized and adapted to fit customer and industry-specific needs in becoming digital enterprises.

The Xcelerator portfolio, by Siemens Digital Industries Software, offers solutions that promote multi-disciplinary design that blends capabilities and skillsets into a collaborative environment, yielding a quality machine design. A managed environment with a flexible product development strategy assists companies in realizing the benefit over their competitors by having the simulation upfront and linking the software to the modules – a great advantage.

Learn more from our article in Industrial Machinery Digest.

About the author

Bill Davis is the Solution Director of Industrial Machinery and Heavy Equipment Industry for Siemens Digital Industries Software. His experience and insights have been acquired from a career spanning 30 years in engineering and operations management with machinery and heavy equipment companies. Bill holds a master’s degree in Business Administration from Marquette University, with a concentration in Operations Management and Strategic Marketing, as well as a Bachelor of Science degree in Mechanical Engineering from Milwaukee School of Engineering.