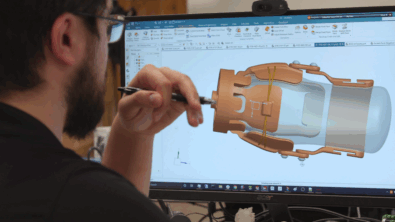

CAD digital twins: transforming product design and engineering

A digital twin is a virtual representation of a physical product, system or process that is continuously updated with real-world data. In the context of CAD, a digital twin starts with a precise 3D model that mirrors the geometry, performance and behavior of the actual product. Engineers can use this model not just for visualization but also to simulate performance under real-world conditions. Unlike traditional CAD models, CAD digital twins evolve throughout the product lifecycle integrating data from sensors, IoT devices and production environments.

How do digital twins work with CAD models?

Every digital twin starts with a CAD model, which provides the shape and parametric details of the product. Once created, the model is enriched with live information. CAD provides the blueprint, and the digital twin turns that blueprint into a dynamic, data-driven tool.

Key functions include:

- Feedback loop: designers detect weaknesses and improve designs before physical changes are made.

- Data integration: IoT sensors feed back performance and usage data.

- Simulation: engineers run real-time analyses of stress, heat or vibration.

Benefits of digital twins in engineering and product design

The advantage of digital twins is straightforward: they help engineers make better decisions faster. Instead of waiting for physical prototypes, engineers can predict performance and spot problems virtually. This reduces cost, speeds up innovation and supports sustainable design choices. For example, predictive maintenance lets companies anticipate equipment failure, while virtual testing reduces material waste. With Siemens NX, engineers can connect CAD and simulation to get these insights early.

How are digital twins used across industries?

Digital twins are applied differently across industries but the goal is the same: efficiency and innovation. In aerospace, digital twins track aircraft health and extend maintenance cycles. In automotive, they simulate vehicle performance across terrains and predict component wear. In manufacturing, they optimize production lines and reduce downtime. In medical devices, they allow for patient-specific designs. Siemens’ comprehensive digital twin brings these applications together across industries

CAD and IoT: connecting digital twins to real-world data

The true power of digital twins comes when CAD models are connected to IoT devices. Sensors embedded in products or machines feed data such as temperature, vibration or energy consumption back into the digital twin. This creates a dynamic representation that evolves as the product operates in real environments. Engineers can then:

- Adjust designs based on actual usage patterns.

- Predict component fatigue before failure occurs.

- Customize maintenance schedules instead of relying on fixed intervals.

This fusion of CAD and IoT is pushing engineering design from reactive problem-solving to proactive innovation. In practice, this means products and systems get smarter over time. Siemens’ Designcenter suite, with NX and Solid Edge, makes CAD and IoT integration possible for everyday engineering teams.

What is the future of CAD and digital twin technology?

The future of digital twins is tied to AI, cloud CAD and immersive visualization. AI will suggest design improvements automatically, cloud CAD will enable real-time teamwork, and AR/VR will allow engineers to interact directly with digital twins.

In short, the next wave of digital twins will:

- Turn CAD into intelligent, self-improving systems.

- Reduce reliance on physical testing.

- Shorten design cycles.

How can engineers get started with digital twins?

The best place to begin is with CAD tools that already support digital twin integration. Siemens’ NX and Solid Edge provide engineers with the ability to create detailed models, link IoT data, run simulations and collaborate effectively.

Next steps for engineers:

- Choose CAD tools that support digital twin workflows.

- Start with a product that benefits from real-time feedback.

- Use simulation and IoT integration to validate designs early.

With the Siemens’ Designcenter suite, engineers can move beyond static CAD toward a connected and sustainable digital engineering process.

CAD software FAQs

Q: What is a CAD digital twin and how is it different from a standard CAD model?

A: A CAD digital twin is a virtual, data-driven replica of a physical product or system that not only includes the geometry and parametric features from CAD, but is continuously updated with live performance data (from sensors, IoT devices, operational feedback). Traditional CAD models are static — they represent design geometry and tolerances but don’t evolve. By contrast, a CAD digital twin bridges design, simulation and real-world data to predict behavior, validate performance, enable predictive maintenance and close the feedback loop across the product lifecycle.

Q: What are the benefits of using digital twins in engineering and manufacturing workflows?

A: Incorporating digital twins in engineering and manufacturing offers several powerful advantages:

- Faster iteration & design validation — simulate performance under real-world operating conditions before building physical prototypes.

- Predictive maintenance & reduced downtime — use sensor data to forecast failures and schedule servicing before breakdowns occur.

- Improved decisions & optimization — test “what-if” scenarios virtually, adjust parameters, and refine design or process settings in the digital twin first.

- Cost savings & waste reduction — avoid overdesign, reduce prototype cycles, and catch manufacturing issues early.

- Lifecycle insight & feedback loops — the CAD base model evolves as the product runs in real environments, feeding back data for future versions.

Q: How do I choose the best CAD software for product design versus product development?

A: The choice depends on the stage and focus of your process. During early product design, you’ll prioritize exploratory modeling, creativity, ease of sketching, concept iterations and visualization. In product development, priorities shift to precision, detailed tolerancing, prototyping, simulation (stress / thermal / fatigue) and integration with manufacturing (CAM, CNC, additive). Other considerations include scalability, cloud-based options, ease of collaboration (multi-user), support for digital twins, AI-assisted tools, immersive capabilities, an open solution, and compatibility with PLM (Product Lifecycle Management) systems. Comparing cost, licensing, training/support and user community/third-party plugins is also critical. Siemens’ Designcenter suite, which includes NX and Solid Edge, are designed to support both product design and product development, offering flexibility from concept creation through manufacturing integration.

Q: What should engineers look for when selecting CAD tools to support digital twin workflows?

A: When evaluating CAD software for digital twin integration, engineers in manufacturing or product development should pay attention to:

- Data connectivity & IoT integration — ability to ingest real-time sensor data, telemetry and operational metrics.

- Simulation & co-simulation support — tools for FEA, thermal, vibration, multi-physics, real-time analysis.

- Interoperability & open standards — support for standard file formats, APIs, digital thread / PLM integration.

- Version control and dynamic model updating — synchronization mechanisms to update the twin as the physical system changes.

- Scalability & performance — ability to manage complex assemblies, continuous updates and high fidelity modeling.

- Enterprise-grade security & IP protection — encryption, permission controls, governance.

- Brand support & ecosystem — having a mature vendor ecosystem, strong support and successful case studies.

For example, Siemens’ Designcenter suite, which includes NX and Solid Edge, enables CAD models to be connected with IoT and simulation for digital twins, giving engineering teams an end-to-end toolset from design through deployment and feedback.