MBSE helps students soar in aerospace competition

For 25 years, the American Institute of Aeronautics and Astronautics (AIAA) has sponsored the Design, Build, Fly competition for students to test their knowledge, organization and determination against others in the field. Every year the requirements are updated and every year, but the overall structure of the competition is designed to introduce the students to the development process for the greater industry and whet their appetite for their career possibilities.

A team of students from University of Michigan have already garnered top honors in this year’s competition, in the first phase of 2 phases in the 2020/2021 competition. University of Michigan’s MACH 5 student team designed, built and tested an unmanned aircraft in 6 months. They not only completed their project on time and to requirements but won the design phase amongst 93 entrants!

The team relied on critical skills learned in a groundbreaking model-based systems engineering (MBSE) course for aerospace that Siemens Digital Industries Software helped develop. Since the next generation of smart products are complex systems of systems that require an MBSE approach, Michigan Aerospace Engineering introduced a new systems engineering and leadership course in 2020. It uses system development lifecycle (SDLC) principles to provide instruction in key systems engineering tools and processes, as well as leadership and business skills.

The competition

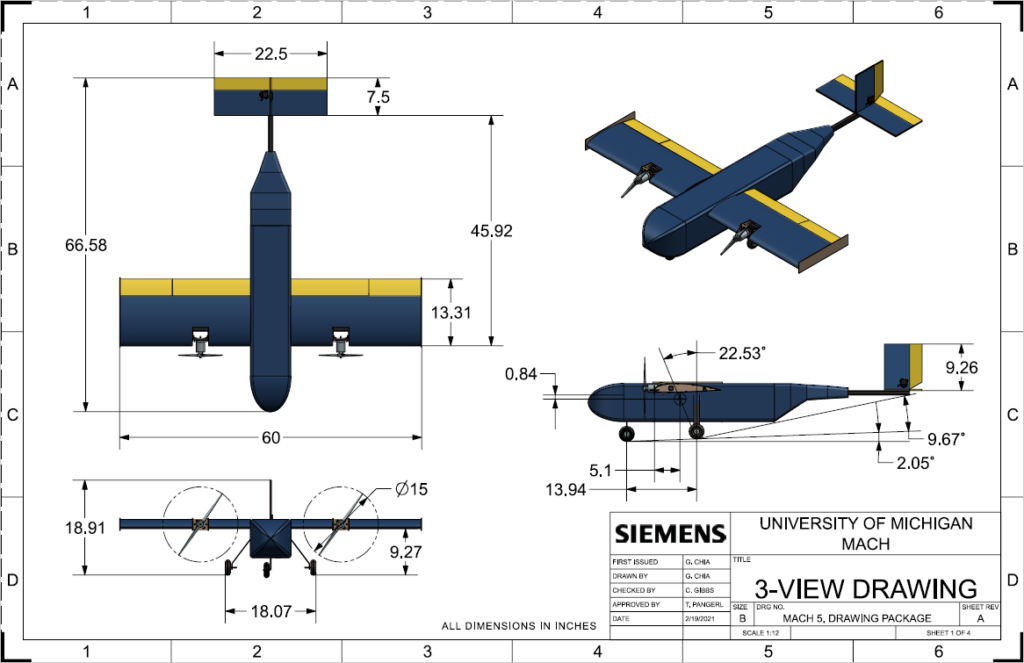

This year’s challenge is to design, build and test an unmanned aerial vehicle (UAV) with a towed sensor array. Beyond the basic objective, there are three missions each entry will complete: flying the course with no payload, flying the course with the sensor payload on-board and flying the course a third time with the payload deployed and retrieved during flight. The results of each test will then be analyzed against each other and compared with other teams’ results for scoring. There are many more specifics on aircraft dimensions and design requirements just as there would be for an aerospace customer contracting an OEM in industry, for the full requirements list check out the AIAA website on the competition. And while there are some clear leaders this year, the final ceremonies are not until May 14th. But completing these missions is practically the last stage of the competition, after team entries are accepted in the fall. Each group of students is tasked with submitting a proposal. These proposals cover a summary of the plan to achieve the required objectives for the competition, an explanation of the management of the project including budget, scheduling and an organizational chart for the team members. There is also a portion of the proposal devoted to the conceptual design of the UAV, the preliminary manufacturing plan and a system for testing the aircraft. This information package is then reviewed as submitted, just as would be the case when competing for production contracts in industry, and the top 110 team proposals advance to the next stage of the competition – the design report.

The design report is essentially the documentation for each team’s design submission, the top reports include design analysis, trade-off calculations, meticulous drawings of the design and detailed manufacturing processes on top of much more. And this is where the benefits of upper-division team members begin to shine. Working on short timescales and with multiple teams working in tandem, the University of Michigan’s students in the MBSE for Aerospace course developed in tandem with Siemens expertise and software solutions from the Xcelerator portfolio – perfectly fit with the project. And this was reinforced by the competition front runners from the university, MACH, in their interview.

Industry processes for academia

MBSE is all about managing an interconnected development process, for industry that means understanding the impact of electrical systems on the complete aircraft or how software interfaces with mechanical components. But the pillars that support industry also align with a smaller project like AIAA’s Design, Build, Fly. The first phase is product definitions and team MACH put it wonderfully, “…we have the overall requirements… we have to narrow them down to individual parts of the airplane… we have to say, I want this part of the airplane to be able to take up this much load.” Product definitions act as guiderails through the development process to bound processes to what is important and tie requirements to systems and minimize wasted resources.

The next phase, or more aspect, of MBSE is Connected Engineering – because aircraft and similarly complex products are essentially systems of systems, each design team needs to be able to work together with a common understanding. For MACH, “[we] send [requirements] out to the individual sub teams, and the sub teams start communicating with each other… to decide on, you know, if I do this, what will you have to do in order for everything to work together.” This is essential every time systems are interconnected but is especially useful when teams are distanced. Public gathering restrictions created a situation analogous to a global supply chain with different teams working remotely and sharing information in context was vital to accurate understanding of such complex systems in a short timeframe.

And the last reflection of where the industry is headed with MBSE is Continuous Verification, though it encompasses much more in industry, it is essentially the manifestation of the guiderails defined in the product definitions, “the design process is really driven by those big requirements.” Complexity, timescales and many more requirements pushed team MACH to implement a hybrid manufacturing approach including additive manufacturing, laser cutting and CNC hotwire cutting in a mix to produce the best design for the flight conditions. And as explained in their design report, each system was tested, sometimes independently to ensure the project would succeed.

Prepared for the future

Boosted by winning the design phase of the competition, the team is excited to compete later this month in the actual flying competition. Although we don’t know the podium winners, the overall effort is clearly a big success in fostering a more involved and experienced entrant workforce. The MACH team members have gained valuable insight into how the aerospace industry works, what the processes of tomorrow’s development will look like and the importance of cooperation in interconnected designs. Good luck to all the teams, but we are rooting for the young pioneers of MBSE for school! After the closing ceremonies we will be sure to follow up with the participants to find out the results and what the plans are for the team next year.