Additive manufacturing – disrupting the future of manufacturing

Manufacturing is changing in ways never thought imaginable.

Though some manufacturers have not yet adopted additive manufacturing (AM), or 3D printing, it is expected to be soon a standard manufacturing method for manufacturers to employ when producing products.

Additive manufacturing removes some restraints commonly found with traditional manufacturing. Adding software, like simulation to the mix, can further refine the printing process by reducing guesswork, streamlining the production process, light-weighting the product, and in some cases, even increasing overall durability.

For these reasons and more, we foresee an inflection point in companies adopting additive manufacturing by 2020.

As this technology continues to evolve, manufacturers across many industries are working to find the correct path to improve their manufacturing processes with additive manufacturing. Moreover, while additive manufacturing is currently adopting many companies, it is poised to play an integral role in the manufacturing process for both small and large businesses in the next few years.

The future of additive manufacturing

The future of additive manufacturing

Adoption of additive manufacturing and future direction

Early adopters of additive manufacturing are investing in materials, processes and applications. One can expect within the next five years that there could be a significant upswing of proven applications for additive manufacturing appearing in the industry.As more companies adopt AM, we can expect that the list of confirmed use cases for the technology will also grow. Furthermore, AM will be eventually following other manufacturing methods and will become highly regimented with process approvals via governing bodies to ensure quality reliable output.

As more companies produce printed parts in larger volumes, and at scale, the price points for additive technologies and materials will continue to drop. Moreover, as printing resolution and techniques improve, new “digital materials” consisting of tunable micro-structures will add new capabilities to traditional materials, ushering in a new dimension of materials science and production.

As additive manufacturing becomes mainstream, industry expansion will also occur in areas outside of manufacturing like education. Increasing investment in curriculum strictly dedicated to advanced learning of additive manufacturing techniques will produce a workforce familiar with AM applications and processes.

Logistically, many experts see additive manufacturing reducing the need for high volume shipping as many products will be able to be printed locally.

Advanced computing power will facilitate the creation of accurate simulations of the physical product and new security techniques will play a role to help protect the IP of these sophisticated new designs and technologies.

Product creation and philosophy of additive manufacturing

In the next 5-10 years, additive manufacturing will become a standard manufacturing technology. Innovative designs will become possible when removed from the constraints of traditional manufacturing methods. Also, these designs will continue to be more efficient and optimized for this purpose. Moreover, consolidation of parts will promote innovative, streamlined designs requiring less maintenance and assembly time.

However, even with its sophistication, additive manufacturing is not a process that exists in a vacuum. Printed parts almost always require post-processing, often using other conventional methods for completing the manufacturing process. Once a print job ends, in most cases, there are still necessary steps to complete the manufacturing process.Therefore, additive manufacturing will continue to be an integrated technology working in harmony with conventional manufacturing.

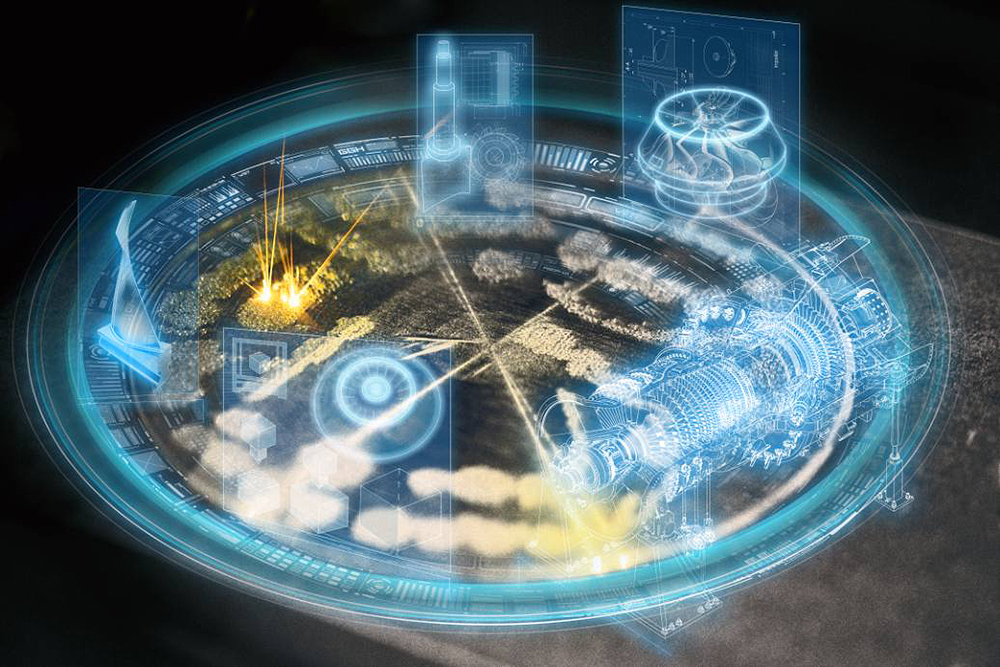

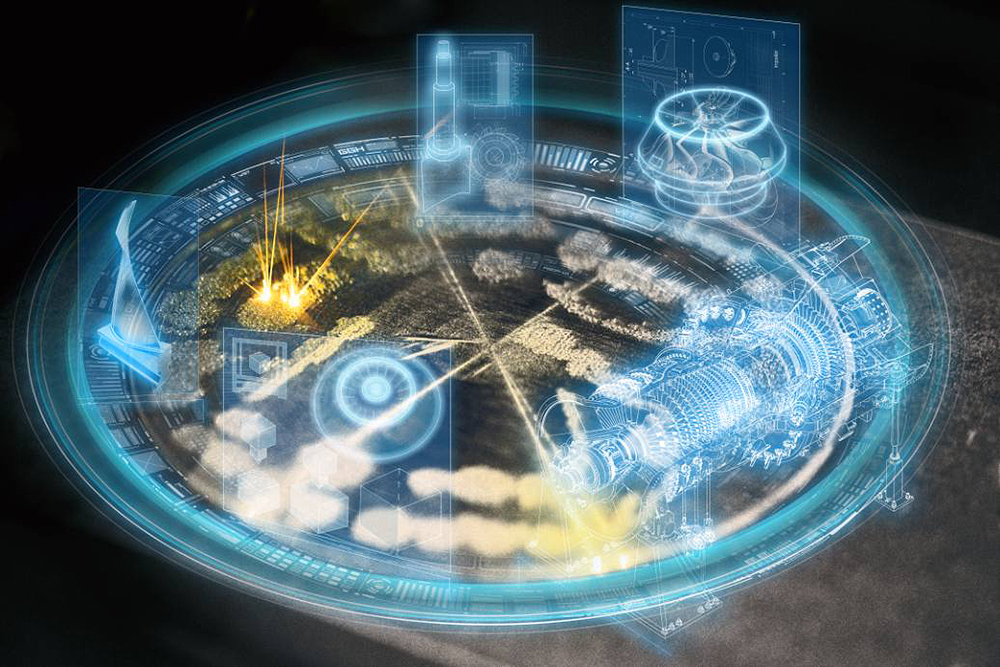

The modern factory – learning, autonomy and AI

With the emergence of additive manufacturing, the concept of the modern factory is experiencing an evolution in thinking.

This evolution corresponds with a spike in interest as to the appearance of the future factor. In the next three to four years, we will see companies scaling up, using 3D printing technology within their existing factory environments. The shop floor will evolve to include not just 3D printers, but also associated facilities for materials management, job scheduling and process management.

An example of a cutting-edge factory in motion is on full display in Finspäng, Sweden, where state-of-the-art prototyping and parts on-demand are being rapidly created for turbine blades and burner tip repair. This dynamic facility continues to implement the latest technologies for tighter integration and orchestration of the manufacturing process. This results in the increasingly efficient production of improved solutions for the market.

One of these improvements is connectivity, which is crucial to evolving from a simple automated factory to a learning factory. A learning factory analyzes data gleaned from various factory devices to gain insight about possible future improvements to the manufacturing process. Imagine a mostly autonomous factory with extreme flexibility to react to new demands and information from the market, using this data to make its own decisions about scheduling, materials ordering and production levels. A learning factory will employ connected devices to gather data, analyze it and appropriately adjust course to meet set production goals and ever-changing demands.

When knowledge about the factory floor pairs with artificial intelligence, there is the opportunity to pinpoint problems before they result in a production interruption or a lessening of output quality. With intelligent equipment, the factory of the future will recognize these issues quickly and resolve them with little or no human intervention.

Impacts on industries

Additive manufacturing is changing trends across many industries, and its growth rate is accelerating. This is affecting many industries across the world.

Like the apparel industry before it, the automotive industry is experiencing a new demand for customized products. One of the largest trade shows each year in Las Vegas is the SEMA show where third-party suppliers show off their products for vehicle customization. Mass customization with lot sizes of one is an area where 3D printing excels.

Another bastion of customization is the medical industry where implants, prosthetics and other implements are being customized to a patient’s unique anatomy. The medical sector was an early adopter of 3D printing, and we expect this industry to continue to use this technology to produce custom solutions to fit patient needs.

Launching one pound of payload into space costs approximately $10,000, so light-weighting of spacecraft and payloads is of paramount importance to the aerospace industry. Again, this is an area where additive manufacturing marries optimization software showing excellent potential.

Finally, the energy industry is finding innovative ways to use additive manufacturing to squeeze new efficiencies out of existing power production processes.

Additive manufacturing – adoption, evolution and continual growth

All these industries will benefit from additive manufacturing as this technology continues to be adopted and continues its evolution into a major manufacturing force for the future.

Additive manufacturing’s future portrays broad trends leaning towards personalization, designing products to one’s personal choice without the overhead price of tooling while providing 3D printing, light-weighting and flexibility for a myriad of products including electric cars, increasing their range with lighter, robust structures.

Also, automation is playing a pivotal role in equipment, marrying the digital and physical world, with problem resolution via artificial intelligence and simulation automatically resolving production issues before physical production ensues.

The value proposition of additive manufacturing expands beyond the magic of modern technology to rolling up your sleeves and implementing the additive manufacturing process cost-effectively and efficiently, revolutionizing the mass production process.

Companies like Siemens have already been in this space for more than a decade with the breadth of end-to-end additive manufacturing technology, including the latest robust hardware and software innovations implemented into the process and equipment for full production.

Additive manufacturing has arrived and will increasingly become a standard production technology that’s integral to making the products necessary for driving innovation in the 21st century.

This concludes part two in a series on additive manufacturing and its impact on the manufacturing industry. Future articles in this series will continue to address the trends and latest news on Siemens’ involvement with additive manufacturing.