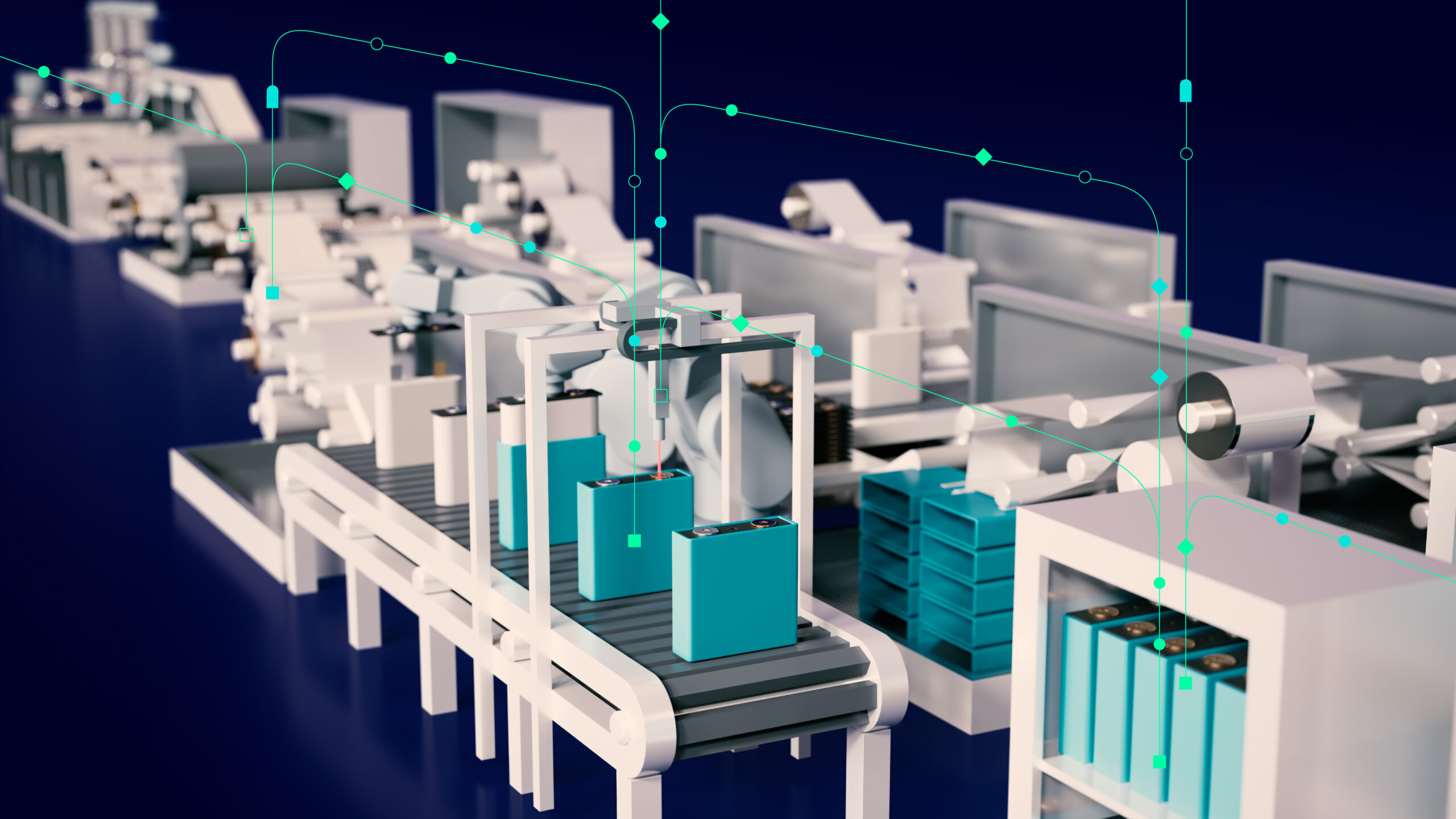

Glocal and Sustainable Battery Production

Battery production is a highly global industry. It has been highly localized for the manufacturing processes, but the supply chains reach around the world. But as more countries around the world see the industry as an enabler to a green future and battery companies themselves are trying to decarbonize, the need to combine the benefits of global and local is becoming evident. The push to glocalize the battery industry is coming from a wide selection of stakeholders and for often divergent reasons. Fortunately, where there is need, opportunity follows.

To talk about glocalizing battery production and meeting net zero targets, we posted a recorded session from Hannover Messe to The Battery Podcast. For the full conversation between the CEO of KORE Power, the CEO of Siemens Financial Services, and the CEO of Smart Infrastructure at Siemens make sure to tune into the episode embedded below. And to get some of the most important points of the session keep on reading.

These three experts are an important example of the kind of work be done in the industry to create the next generation of battery manufacturing. KORE Power is in effect trying to break up the regional dominance of the battery industry to capitalize on the expected growth of the US domestic market. To make that happen, they have garnered the support of Siemens Financial services to finance the project and tapped Siemens’ Smart Infrastructure group to help plan out the endeavor.

Bringing an industry like battery to the United States is not a trivial task. It means the pool of experienced workers is not as easily accessible as they would be in Korea, Japan, or China. But it also brings supply challenges, battery value chains wrap the world over and establishing a new end-point is chief along them. Manufacturing batteries locally still relies on global raw materials, hence the glocalization transition.

Building a glocal production facility is linked to it’s region, and can only be sustainable long-term by understanding the ecosystem of which it is a part. Experienced workers come from investments in the community through education. Supply chains are fostered through strong partnerships and mutual success. And understanding the demands of manufacturing helps mitigate the impact on the natural world such that the business can be successful well into the future. Looking beyond the factory can have wide ranging benefits to the success of a business.

This brings us to the importance on having someone from Siemens Smart Infrastructure on stage for this discussion. In Matthias Rebellius’ words “smart infrastructure is sustainable infrastructure.” Only using lighting or climate control when necessary saves the energy consumption of a factory while efficient drive systems and optimized production processes reduce the constant load and per-unit emission of battery cells. And installing solar on-site or operating with insights from the regional electrical grid help reduce the carbon emissions from electrical generation even further. Every kilowatt matters on the road to net-zero. That starts with accelerating your industrial transformation like KORE Power has done in the past few years as it builds out glocalized production capacity in the American Southwest.

For more information on the battery industry in general, be sure to check out our website siemens.com/battery. And if you want to know more about how KORE Power SFS and Smart Infrastructure have worked together to build something great, the recording is full of information I couldn’t get to here. And if these are the kind of conversations you want to hear around battery, subscribe so you don’t miss future episodes.

Want to watch the full discussion instead? Here is the video recording from the event.

Siemens Digital Industries (DI) is a leading innovator in automation and digitalization. In close cooperation with its partners and customers, DI is the driving force for the digital transformation in the process and manufacturing industries. With its Digital Enterprise portfolio, Siemens provides companies of all sizes with all the necessary products, along with consistent solutions and services for the integration and digitalization of the entire value chain. Optimized for the specific requirements of individual industries, this unique portfolio enables customers to enhance their productivity and flexibility. DI continuously extends its portfolio to include innovations and the integration of future-oriented technologies. Siemens Digital Industries, with its headquarters in Nuremberg, has a workforce of around 72,000 people worldwide.

For more information on Siemens Digital Industries products and services, follow us on LinkedIn, Facebook, Twitter, and YouTube.