Drivers of the Marine Industry – Transcript

Dive deep into the future of ships with The Marine Industry Podcast Series, an all-new podcast all about the technology behind the marine industry. To kick off the inaugural episode, Jan van Os, Vice President of the Marine Industry at Siemens Digital Industries Software, and Dale Tutt, Vice President of Industry Strategy at Siemens Digital Industries Software, discuss the main trends driving the marine industry’s direction.

Listen to the original episode or read below for the transcript.

Blake Snodgrass: Hello and welcome to our first podcast of the Marine Industry Podcast series. I’m your moderator, Blake Snodgrass, writer for the thought leadership team at Siemens. I’m joined by our special guests and industry experts. Jan van Os, Vice President of the Marine Industry at Siemens Digital Industries Software, and Dale Tutt, Vice President of Industry Strategy at Siemens. So welcome Jan and Dale. Let’s get started by each of you providing a brief bio of your experience and background for our listeners.

Blake Snodgrass: Can we start with you, Jan?

Jan van Os: Yeah, thanks Blake. My name is Jan van Os. I’m the industry lead for Marine within Siemens.

And yeah, so my background. Before I joined Siemens in 2017, I worked nearly 30 years for a company called Damen Shipyards in the Netherlands, and after my graduation and my thesis I started working there in the research and Development Department. Yeah, I did a handful of different jobs within the company in the years after that. Before I joined the repair and conversion division. I worked there for 15 years and ended up being a managing director of one of the ship repair yards.

Jan van Os: Then I stepped back into the new building being a project director for a big project in Romania and after that in 2010, I became the project, let’s say the project director for offshore and transport, responsible for design, for development, marketing of the more specialized and more complex products within the Damen Shipyards group and then in 2017 Siemens called me and said, “Okay, do you want to join our team, our industry team and support us to grow in the marine business?” And that’s how we ended up here.

Blake Snodgrass: Excellent. How about you, Dale?

Dale Tutt: Hey, thanks Blake, and thanks for having me today. So, I lead the industry strategy team here at Siemens. I joined in 2019 in the industry strategy team. We develop industry focused solutions and overall strategy where we need to develop new products and where we need to go to market across the entire globe with all of our solutions. Before that I was the Aerospace and defense industry lead here, at Siemens and before joining Siemens, I was in the aerospace and defense industry for many, many years, leading a lot of engineering programs, program management teams in many different roles. I had a lot of background, a lot of different experiences.

Dale Tutt: But right before Siemens, I was a vice president of engineering at the Spaceship Company where we were working commercial space tourism. And then before that, I was at Textron Aviation, and I had led a number of programs. But towards the end of my career there, I had led the development of the Textron Airland Scorpion jet, which was an all new aircraft that we developed from a concept sketch to 1st flight Tutt, Dale (DI SW ST&MK ISME IND)

in 23 months. We used a lot of digital tools to help make that happen go fast, and so I’ve had a lot of background using PLM and CAD and all the analysis tools and simulation tools to help companies go faster with their programs. So, looking forward to the discussion today.

Blake Snodgrass: Great. Thanks for providing those bios. Those are impressive. It’s great to know that we’re talking to experts in their field.

Blake Snodgrass: Let’s begin by discussing the current state of the marine industry. I know that the International Maritime Organization has come out with a strategy that envisions a reduction in carbon emissions by at least 40% by 2030, going up towards 70% by 2050. So Jan, with that kind of agenda or goal in mind, what do you see as some of the current trends or drivers of the modern shipping industry and its future in getting to that next level?

Jan van Os: Yeah. Sustainability is I think the most important trend and driver for the industry at the moment. And you mentioned already the IMO setting, some regulations for the coming decades where shipbuilders and ship operators have to comply with.

Jan van Os: And that’s really driving everything what we are doing. Not only to shipyards. It is driving what our suppliers are doing, what class societies are doing and what the eventual appliance of the ship to ship operators are doing. And let’s say if you look at what the IMO said, it’s at the moment even with the social responsibility of some of the bigger companies which are transporting the goods around the globe and containers or in bulk or in liquids, they already said “Okay, we have to do it faster, and IMO is setting great requirements for the industry, but we want to do it faster.” Like, Maersk is already saying, okay, by 2040—which is 10 years earlier than the IMO is saying—they say, “We want to have zero emission ships. Our whole fleet should be zero emission, so no 50% reduction no zero emission.”

Jan van Os: And more and more of those big shipping companies are setting targets which are sharper than what international regulations is giving. So that is that is a good thing for the environment and it’s not only marine industry. It’s also aerospace and defense, automotive. But our industry is moving even faster than the requirements which are set. So sustainability is the key driver. But there are three other different key drivers which are also important and which are also a little bit connected with sustainability.

Jan van Os: Cost effectiveness, increased efficiency, which is also reducing the CO2 footprint, so also related to sustainability, but the shipping industry is an industry with low margins, and with all the crises which we have in the past decade like the oil crisis but also the COVID crisis recently that’s affecting the industry quite a bit. So that means that ship operators need to have the lowest cost of operation. So that means that shipyards have to design and build the vessels compliant to their needs. So that’s an important part.

Jan van Os: With this all set, cost effectiveness, sustainability, also the ships are getting more and more complex. If you think about let’s say more sustainable propulsion systems, then that is much more complex than just a diesel engine. So you think about hybrid systems, methanol ammoniac or sales. So everything is getting more and more complex. More cables, more sensors, more autonomous things, more interconnection and that’s then also the 4th key driver into connectivity onboard. The ship is very important and you can look at it in two ways. It’s not only interconnectivity for the ship designer and the shape builder, to have connection with their suppliers and with the co-makers with the clients and class societies, which are all divided over an area or in the zone, or even around the globe. But it’s also the ship itself.

Jan van Os: The crew is there. The crew wants to stay in contact with their families, but more and more important that the ship is connected with the home base, to have a transfer of information. How is the ship performing? How is the fuel consumption? What do we need to repair? Can we make sure that the ship is lasting to the next port? Or can you arrange the repairs in the next port so when the ship is there for 24 hours that you can do the repairs. So that is one of the things which is important and connectivity on, yeah, in the middle of the ocean is still, let’s say it’s possible.

Jan van Os: It’s being done, but the bandwidth which is available is not always the highest. So that’s still something to work on for the satellite companies. But we also need that to go eventually to autonomous shipping. And if you really look at the future of the shipping industry, then we are going to semi-autonomous or autonomous and that makes this a key trend also a driver for the coming decades.

Dale Tutt: Yeah. Yeah, those are pretty interesting points. We have, you know, we see this in a lot of industries with the complexity and the autonomy and the need to go faster and obviously sustainability is affecting everybody. But let’s touch the base on that autonomous a little bit more. You talked about the connectivity, but then you also talked about autonomy. So I know what autonomous means when we talk about automotive applications or even aerospace applications with unmanned crew, or I’m sorry unmanned systems, but does autonomous, what does autonomous operations mean for, on a ship? Does it mean zero crew? Or does it mean something else?

Jan van Os: Yeah, in the end it will mean zero crew, but it’s not always that easy that you can sail with, with zero crew because of the international regulations. And when you stay with a ship in local waters and you have to comply with only one regulation within a country, and so you stay within their territory. It’s a little bit easier and you are close to shore. The problem with autonomous, fully autonomous, is that when you are sailing across the Atlantic then you are in the middle of the Atlantic. So you cannot reach the vessel that fast. You cannot go by helicopter anymore. If you want to go by ship, it will take a couple of days. So when something is happening, or think about piracy, if somebody’s entering the ship, you cannot actually be there quite fast.

Jan van Os: And the biggest problem is it maybe that it’s also piracy, but it’s also when something is happening and you have an oil spill or you have a leak, what to do? So the liability and insurance companies and also the international regulations that makes it a little bit more complex to have fully autonomous ships sailing across the oceans, let’s say within the the coastal waters, yeah, it’s already happening. If you look at the first ships and [unintelligible] the first ship, also electric, fully electric, starting to sail across the coast of Norway.

Jan van Os: So it’s all possible. Technology is there, but to do it worldwide, it’s still a challenge. So if you look at the future then and you took that, you can take the same levels which are in the automotive, level 0 to level 5. I think that the most ships are all ships, they have level 1 to level 2. And now they’re going to Level 3. But let’s say the real future, to my opinion is level 4 for, let’s say, more international voyages across the oceans and level 5 in in coastal waters. And that’s where we are going to because let’s say, crew onboard a vessel is approximately 1/3 of the cost.

Jan van Os: So if you add everything up and you can save, let’s say, maybe 80% of that cost, then you can reduce your operational cost but with quite a bit. And also the shortage of sailors. If you look now worldwide, there’s a big shortage of sailors. So that’s also solving a problem. Autonomous is solving the problem about getting skilled people onboard your vessel, and you know that in the aerospace and defense now not everybody who is growing up wants to be an aerospace engineer or wants to build a ship or wants to sail on a ship. So that’s a real problem in our industry and autonomous can solve those issues for a big part.

Dale Tutt: Yeah, that’s pretty interesting. I hadn’t really thought about that, some of the implications of operating autonomously. But so one question I have about a little follow up on that is when you do have autonomous operations on a ship, do you find that the crew actually needs to be more highly trained in because they now have to do more? So if you have, you know, 80% less crew, do they have to cover more areas of the ship or as a as a result of the autonomous operations, so does this actually change how you train the people that are working on the ship as well?

Jan van Os: Yeah, I think that will change as well because they will be more operators than actually working on the ship. Let’s say if I take the engine on which is the heart of the ship, you have the captain with his crew, and you have the engine room, but let’s say if you have Level 5 autonomous then you need somebody to operate still the engine room but more on a let’s say multi skill because he can connect to the home base where the real engineers are sitting or the real mechanics are sitting and they can help him to solve the problem. So you need somebody who’s not specialized in only one part because you have, normally, the electrician, you have so many for the engine, and probably also somebody for other stuff onboard.

Jan van Os: If you have some systems mobile board which are specific, but now you need somebody who’s more multifunctional and will be assisted by people on shore. And if you have a connection and they have a digital twin and where they can simulate some problems, look at it and give the people onboard the right instructions to repair or to optimize something. So that is that is changing the way people are working onboard a ship, but also how they are educated in the future. That’s a very good question, and that’s also a thing where the industry is going and have to be prepared to go there. So you go, we have higher educated people onboard, more higher educated people.

Dale Tutt: No, that’s cool. That’s a pretty that’s a pretty great application of the digital twin. And in a way that a lot of times people don’t think about it. So thank you.

Blake Snodgrass: Yes, and thanks to you both. We’re going to have to close out for this first episode. I want to thank both Jan van Os and Dale Tutt for their input on providing some of the drivers of the current state of the marine industry. But please stay tuned for future podcasts further detailing sustainability and shipping. Until then, thanks for joining us.

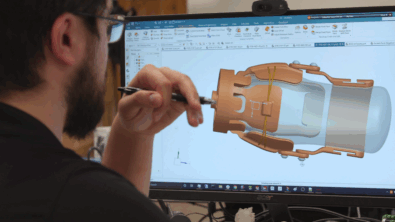

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries, Siemens Digital Industries Software is where today meets tomorrow.