Expanding MBSE to elevate the A&D industry

Model-based systems engineering (MBSE) has played a significant role in the aerospace and defense (A&D) industry for decades, more than nearly every other industry. In displaying that head start, our Vice President of A&D Strategy and Marketing at Siemens Digital Industries Software—Todd Tuthill—was a featured panelist in the International Council on Systems Engineering’s (INCOSE) webinar about the future of MBSE. Todd’s experience with MBSE over his aerospace career provided many valuable insights to the conversation.

Most notably, Todd suggested there are opportunities to expand MBSE even further than seen today and make A&D programs even more holistic. Instead of simply modeling aspects of engineering, an MBSE solution can be expanded to connect data across product domains and lifecycles. It can also pave the way to automating repetitive tasks. Taking advantage of these opportunities will be critical as the industry faces new challenges like sustainability, as well as a worsening engineering labor shortage.

Building a holistic approach with MBSE

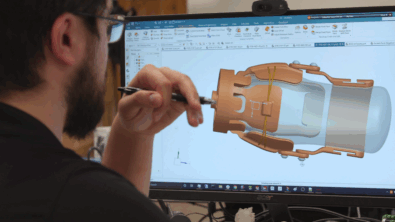

To start, Todd defines MBSE as the digital transformation of systems engineering. Historical methods of systems engineering in A&D have long relied on numerous paper documents from a lack of alternative options. With the growing complexity of designs and workflows, paper and digital document-based processes have become incredibly inefficient. The swell of digital technologies like models and the digital twin, though, lets companies reduce the risk of missed targets and exceeding costs in new ways.

That said, the best application of MBSE is not treated as its own isolated engineering domain. Siloed domains are a critical issue in the A&D industry today. The absent connections of crucial data across a product lifecycle creates delays to market businesses cannot easily overcome. The right MBSE solution has the capability to connect engineering aspects from design to manufacturing to product support, but if companies simply use it to build models of individual systems, they will not solve all their problems in time. To get the full return on investment from MBSE, A&D companies must apply it holistically to connect data across the entire product lifecycle.

This holistic approach is especially valuable as the industry moves toward with more environmentally compliant aircraft for a sustainable future. Alternative energy sources like electric batteries or hydrogen will impose new design constraints that will affect most if not all aircraft components. They will impact everything from the power supply system to the mechanical structure of the aircraft itself. Balancing these requirements with the numerous interactions of the new product systems can be very difficult without the assistance of digital technology. MBSE utilizes such technology, allowing engineers to track requirements and model system interactions from the beginning.

Paving the way to automaton

In the webinar, Todd also explains how MBSE can assist engineers by automating mundane tasks with a story from his own career. Years ago, Todd and his team were testing the commercial flight control system of an aircraft when he realized that they were spending too much time writing paper documents, converting the documents into a test script, and putting the test results together into a report. He then challenged the team to create a model of the test process, create a test script, and collect the results for them. When the client still wanted a paper document of the test procedures, they just had the model make that too, and were able to perform 10 to 12 tests before delivering the aircraft on time. With MBSE, Todd and his team were able to automate the mundane task of gathering data, enhancing their testing capabilities while sticking to their timeframe.

Such automation may help alleviate the increasingly troubling engineer shortage the A&D industry is experiencing worldwide. The industry is currently lacking tens of thousands of engineers, which is expected to rise to unsustainable levels by 2030. Finding enough engineers to fill those gaps is a challenge that needs a solution, but in the meantime, the ability to automate tasks with MBSE can let existing engineers dedicate more of their time to more valuable engineering processes. When assisted by the digital twin, a smaller team of engineers can do more than a larger team relying on paper documents, decreasing the strain of the engineer shortage.

The future of MBSE in A&D

There is plenty more to talk about regarding MBSE, but the insights shared by Todd here demonstrate just how beneficial it can be to the A&D industry. It has already helped engineers digitally transform many aspects of engineering and can be applied further to connect critical data. By utilizing this holistic approach with MBSE, companies can also automate aspects of the engineering process and empower engineers to find more innovative designs. MBSE has been playing a key role in A&D for a long time, but now is the time to truly expand its capabilities and bring A&D design to the next level.

Watch the full INCOSE webinar to listen to the entire conversation and gain more insights about MBSE.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries, Siemens Digital Industries Software is where today meets tomorrow.