MBSE allows the A&D industry to soar

Model-based systems engineering (MBSE) has enormous potential to help companies across different industries adapt their development processes for the shorter development cycles expected today. Recently, a group of experts from Siemens gathered at the Engineering Roundtable on Engineering.com to explore just how MBSE can be applied to different industries. Representing the aerospace & defense (A&D) industry was Todd Tuthill, Vice President of A&D Strategy and Marketing at Siemens. Todd brought up many benefits MBSE provides for the A&D industry, including the management of increasing product complexity, the empowerment of agile development, and its ability to help address the shortage of aerospace engineers.

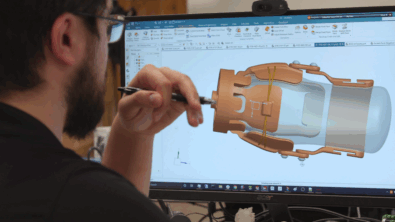

The A&D industry is actually an early adopter of MBSE because of the immense complexity of aircraft and spacecraft, which is only continuing to grow due to the integration of advanced software and electronics with mechanical systems. Due to the physical scale of many aerospace products, integration of these advanced systems is too complex for traditional document-based systems engineering to handle, as the numerous interactions between components can result in millions of isolated paper documents. Thus, A&D companies have turned to MBSE for its ability to integrate all the information about an aircraft or spacecraft across its entire lifecycle, as opposed to the isolated information silos that arise from document-based systems engineering. All that information can be accessed through a digital twin of the product, making it easier for engineers to access data they need. The early adoption of MBSE by A&D has allowed companies to navigate the limitations of traditional systems engineering, and it will pay off as aircraft and spacecraft systems become more complex.

Using MBSE also allows A&D companies to utilize agile development processes to greater effect. In the discussion, Todd explained how A&D companies had traditionally followed waterfall development processes, trying to perfect products from the beginning and test later for any defects. The flaw in this method is that defects will not be known until the later stages of the product’s development, and once they are discovered, engineers will have to go back to the beginning to correct them before testing all over again. By contrast, agile development, constitutes a more flexible development process by addressing defects when they arise. MBSE’s integration of the entire product lifecycle helps achieve agile development with digital technologies such as, for example, IT/OT sensors. When implemented on operating products and systems, these sensors can feed real-time data back into design and manufacturing, where any discovered defects can be corrected with minimal losses. This method allows defects to be discovered quicker and adapts the development process to overcome them, making the process more flexible, durable, and agile.

Another challenge Todd highlighted which MBSE could solve is the shortage of aerospace engineers the industry is currently experiencing worldwide. The roots of this crisis lie in data and information, as many of the engineers who have worked in the industry for decades are now retiring, taking their valuable knowledge and experience with them. Additionally, engineers spend too much time processing data for projects, leaving them with less time to perform any actual engineering and forcing companies to recruit more people to keep up with demand. MBSE can alleviate these by not only digitally storing and institutionalizing legacy engineers’ knowledge for the next generation, but also by what Todd calls “automating the mundane.” This utilizes algorithms to automatically acquire data from a system for engineers, allowing them to spend more time making decisions from the information rather than hunting for it. By delegating the mundane work to automation, new engineers can do more actual engineering and make up for the labor shortage.

Todd’s points in the Engineering Roundtable highlight how MBSE can benefit not just the A&D industry, but other industries as well. As an early adopter of MBSE, aerospace companies have been able to better manage increasing product complexity with agile development processes and will be better able to navigate the shortage of aerospace engineers. Whatever the challenges the A&D industry may face in the future, MBSE will be a vital tool overcoming them and helping the industry thrive.

To learn about the other benefits A&D and other industries gain from MBSE, watch the Engineering Roundtable on Engineering.com. If you are short on time, check out this quick summary here.

Siemens Digital Industries Software helps organizations of all sizes digitally transform using software, hardware and services from the Siemens Xcelerator business platform. Siemens’ software and the comprehensive digital twin enable companies to optimize their design, engineering and manufacturing processes to turn today’s ideas into the sustainable products of the future. From chips to entire systems, from product to process, across all industries, Siemens Digital Industries Software is where today meets tomorrow.