Rethinking systems engineering

Innovation in the aerospace industry is almost taken as a given at this point, in a matter of decades we propelled ourselves into the skies and then beyond them into the reaches of space. But making that happen is a concert of hundreds and thousands of interconnected systems and without a framework to conduct development, it will fall flat. This has traditionally been handled through systems engineering and even early implementations of model-based systems engineering (MBSE), but the growing reliance on software and electronics in aircraft is stretching these methods beyond their capabilities. Let me explain, or for a deeper explanation check out the book.

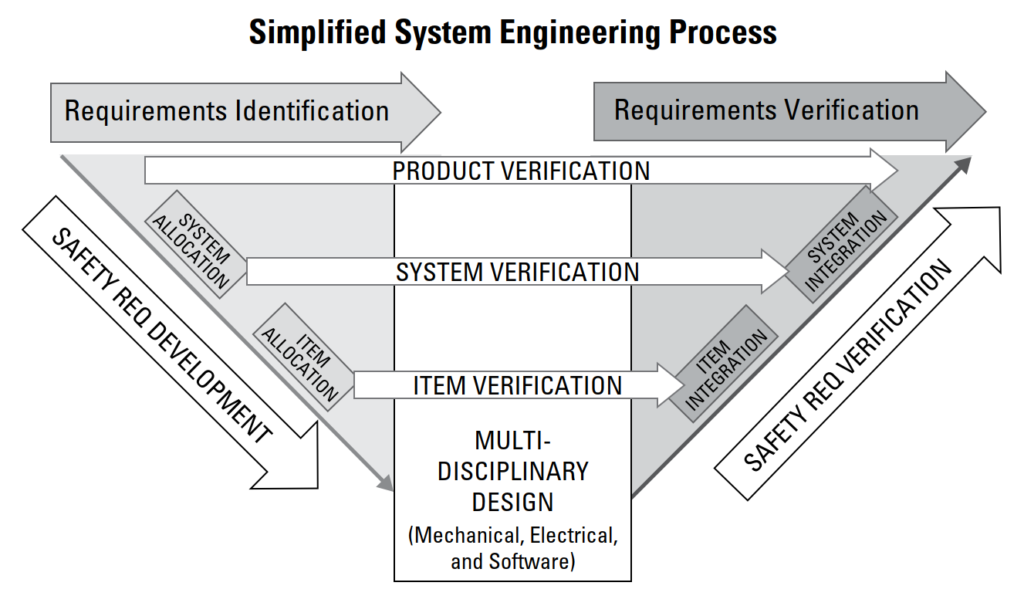

Most complex engineering programs adhere to the V-Diagram, where requirements are balanced on the left-hand side of the V and validation is conducted in later stages of the development process, as seen in the diagram. For single-domain applications, where perhaps mechanics are the only realm of engineering is require, this model for systems engineer worked well. It was highly linear and phased, but as multi-domain systems emerged the relationships between mechanics and electronics began to muddy the application of the V for development. Companies began adopting MBSE to combat some of the complexity of joining the mechanical and electrical worlds, but the continued innovation and greater reliance on software if aircraft has left this document-based approach a tenuous solution as well.

Instead, development required a digital solution where everything could be accessed in a few clicks rather than through information requests from a filing system. This retained the name MBSE, but the model holds far more weight with a reliance on the digital twin and the digital data flows between domains of an aerospace project. The systems engineering workflows also took some cues from the development worlds being integrated – software was already a highly parallelized development domain so many practices were coopted to create an AGILE approach to systems engineering. This shift from linear timeline to parallel workflows was the final strand cut in the divergence from the V-Diagram.

The iteration required between three very different development domains was extending project timelines, which directly impacts the viability of new products, especially so in aerospace where overruns have massive costs. Detailing the design requirements and decisions within the digital twin as a single source of truth enabled teams to work independently but cohesively on these large and complex products. A design change in the electronics systems are noted and evaluated in the other domains to ensure it still fits into the physical requirements or that the device can still communicate with the on-board software. Adhering to the V would mean every system is designed in complete isolation and brought together later in development where inconsistencies are revealed.

Though inconsistencies are not eliminated within a digital MBSE workflow, they are uncovered far earlier in development because the design requirements available openly across development. Expanding the size of an electronic control unit could even initiate a system check to ensure it still fits the specifications. Using a comprehensive tool set enables better communication between each of the domains to build the smart and connected aircraft of tomorrow even faster. But getting there requires a standardized language like SysML v2 to facilitate the interoperation and robust software tools that can handle these new requirements. But to understand the solutions afforded by MBSE in greater detail, the Siemens Special Edition MBSE for Dummies is a great place to start. And if the discussion here made perfect sense you might even be able to skip chapter two, but there is a lot of great information left to learn.

Siemens Digital Industries Software is driving transformation to enable a digital enterprise where engineering, manufacturing and electronics design meet tomorrow. Xcelerator, the comprehensive and integrated portfolio of software and services from Siemens Digital Industries Software, helps companies of all sizes create and leverage a comprehensive digital twin that provides organizations with new insights, opportunities and levels of automation to drive innovation.

For more information on Siemens Digital Industries Software products and services, visit siemens.com/software or follow us on LinkedIn, Twitter, Facebook and Instagram.

Siemens Digital Industries Software – Where today meets tomorrow