E-book: Smart data – next steps in digitalization

Accurate manufacturing data is required to adjust processes and to ensure quality over time. This is difficult because not all data is in the same format and not all sensors perform the same over time. How do you know what the best data to collect is and how to filter out the junk data from useful or smart data? This is not an easy task when the interfaces to data collection sources are complex, and they do not speak the same language, often requiring the vendor’s help to get data out of the machine and then spending time normalizing the data to turn it into something useful. This is a challenge for companies trying to set up a custom data collection system by themselves.

With internet of things (IoT) technology entering the manufacturing world, you can take your efficiency and waste-reduction efforts to the next phase using big-data analytics. Advanced big-data analytics can help cope with the sheer number and complexity of production activities that influence yield, providing a granular approach to diagnosing and correcting process flaws.

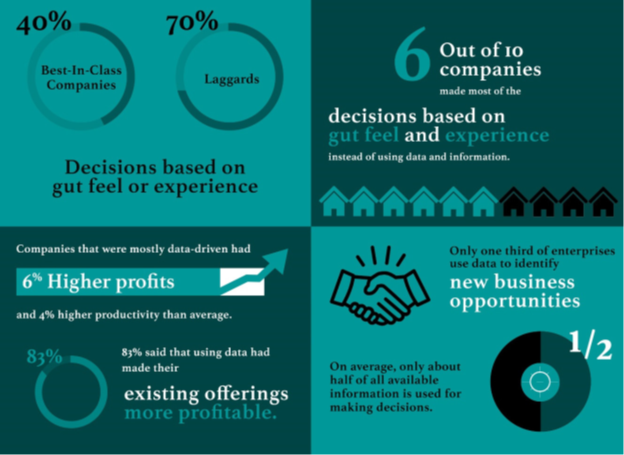

High-tech manufacturing processes generate huge amounts of data. However, approximately 70 percent of that data is not used, according to research at MIT, either because it has not been collected or because of the lack of a platform to use data intelligently to drive informed business decisions.

To help your factory take the next steps in the journey to digitalization, we authored “The Printed Circuit Assembler’s Guide to: Smart Data, Using Data to Improve Manufacturing.” In this e-book, we look at some of the major hurdles that your teams might face in collecting manufacturing data that then will be useful, not only for improving processes but also for improving materials and supply chain management, tracing the sources of problems and defective or counterfeit parts, and providing trends analysis for business forecasting and reporting.

This e-book includes the following:

- We look at the challenges of collecting good data and where collecting it makes sense for the factory and improving the business.

- We examine what makes data smart, meaning the difference between data on its own and the analytics.

- We cover how data can be distributed from the underlying infrastructure for external use. Also, we detail some of the tools available today to help you put these principles into practice and look at a real-world example of how companies are reaping the benefits of putting their data to good use with analytics.