White paper: virtual commissioning – digital twins to validate

A recently published white paper discusses how virtual commissioning uses software tools with preexisting hardware-in-the-loop (HiL) to simulate and validate the product fit, function, safety compliance, control and performance.

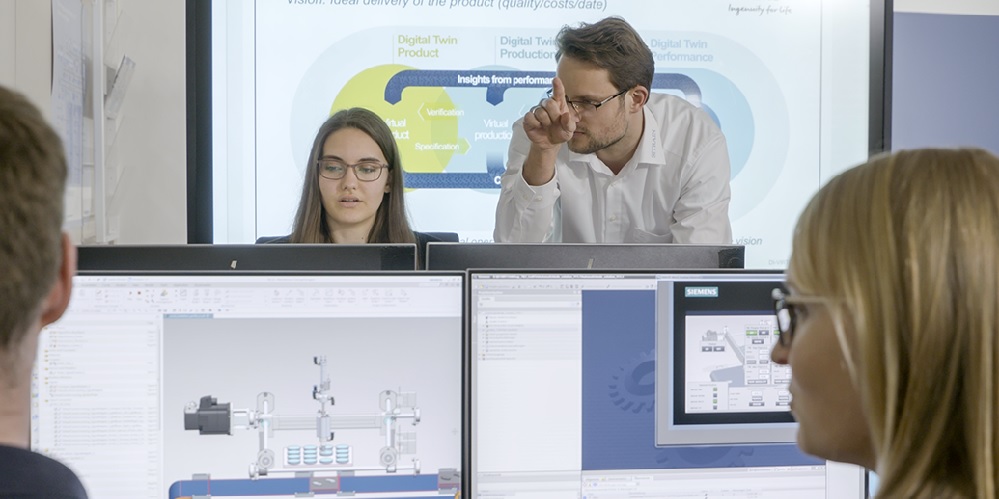

Using virtual commissioning tools with hardware and software

New virtual commissioning tools unite with hardware and human operators to simulate validation testing that results from product requirements. Moreover, virtual commissioning empowers testing more quickly, including tests that are potentially damaging or challenging to execute, providing useful product insight. The data captured from physical products with IoT can drive virtual models to ensure real-world scenarios for verification and validation.

This functional machine model’s benefits include simulation, using programmable logic controller software and human-machine interface (HMI) inputs. The behavioral 3D operational model demonstrates the kinematic behavior response initiated by the PLC code or user interaction with input devices. So, in the model, users open and close doors, interact with the HMI and other interfaces.

Also, virtual commissioning allows initial training, including remotely, a useful capability in our COVID-19 environment. So, operators and technicians will test software to control concepts virtually. Subsequently, a real environment with physical controls drives the virtual machine controls of the physical machine. This process provides the flexibility to test ideas early, improve products, and perform pre-production training for the startup to be quicker and more productive.

Installing and commissioning issues

Installing machinery is a complicated and costly process. Large and heavy machines are expensive to ship and usually require assembly on-site, needing positioning specialists, including electricians and mechanics for testing. Often this is the first time the whole machine has been assembled, and surprises happen. This process includes mating modules, interfaces and verifying design and development issues.

Moreover, sensors and controllers must manage real-world physical glitches with raw material variances, signaling sensor and timing issues. Most operators possess only cursory training, basic setup and operation, so it can be a time-consuming process, delaying machine production. Also, electronic components have shorter lifecycles driven by the high-volume and high-tech electronics industry. As components become obsolete, machine builders must update the designs with modern, updated replacement components.

Software integration typically occurs later in the machine development lifecycle. Therefore, machinery measures lifecycles in years or decades, so software is managed and updated throughout the process. Because software lasts for decades, it isn’t easy to find human resources for technical support. It’s crucial to ensure it is bug-free as the code is modified and extended over many years.

Therefore, the software is an essential element of the process within virtual commissioning. Multi-domain configuration management capabilities are necessary for embedding software with the build configuration, including monitoring field updates with the as-maintained configuration. A machine’s life requires multiple upgrades and capability additions —hardware and software, control system changes and additional modules for expanding a machine’s capabilities that support the end customer’s product mix. Possessing an accurate and comprehensive digital twin validates multiple changes, saving immeasurable hours of machine downtime.

Siemens advanced machine engineering solution

Siemens Advanced Machine Engineering (AME) is a subset of the Xcelerator portfolio that supports machine-building companies by providing appropriate portfolio technologies to support multi-disciplinary design, configuration management and virtual commissioning.

A critical part of advanced machine engineering gives life to a model, thus enabling commissioning to happen virtually. It provides a library of reusable data for building a machine’s concept, motion definitions, sensors, actuators, collision behavior and other kinematic properties. Virtual testing is supported, so machine functions can be validated much quicker than a physical product, enabling more verification and validation.

View the CIMdata virtual commissioning white paper for more information.

For more information on Siemens Digital Industries Software products and services, visit siemens.com/software or follow us on LinkedIn, Twitter, Facebook and Instagram.

Siemens Digital Industries Software – where today meets tomorrow.