The latest in scan test and volume scan diagnosis

A new technique increases the throughput of scan diagnosis, leading to better failure analysis and yield improvement.

Scan test is the de-facto standard method of testing digital circuits. When a device is under test, it is put in a known good state, test patterns are applied, and a certain set of values are expected back. But what do you do when those expected values don’t come out? That’s where scan diagnosis comes in; figuring out what has gone wrong in the design.

Mentor product manager and scan diagnosis expert Jayant D’Souza recently spoke to Semiconductor Engineering about scan test, scan diagnosis, and how to address one of the biggest challenges – diagnosis throughput.

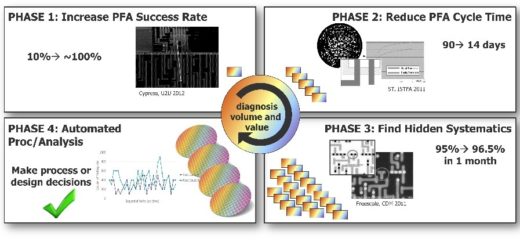

Scan diagnosis helps product engineers find the cause and location of defects in manufactured ICs. The process is based on simulation of the data from many failing test cycles. Scan failure data provides the basis for many decisions in the failure analysis and yield improvement. It helps in the selection of failed devices for physical failure analysis, finds hidden systematic failures, and helps direct design and manufacturing decisions that will ultimately improve yield.

However, as design sizes grow and 3D transistors present new defect modes inside the cell that require cell-aware diagnosis, turn-around-time suffers and compute resources can’t keep up with demand. In terms of diagnosis throughput, which is a function of the time needed to create a diagnosis report and the amount of memory needed for the analysis, this situation is not ideal. The higher volume of diagnosis you can complete, the higher the value of diagnosis.

How could you improve the throughput of diagnosis? By either reducing the amount of memory needed or by reducing the diagnosis time, or both. D’Souza describes a technique called dynamic partitioning that significantly improves the diagnosis throughput. It reduces both the memory requirements and the diagnosis runtimes by reducing the input file sizes. Dynamic partitioning works by first analyzing a fail log and then creating a partition that contains only the parts of the design that are relevant to that fail log.

Dynamic partitioning was created to address hardware resource limitations by greatly reducing the memory footprint of the diagnosis process performed by the analyzers. With dynamic partitioning enabled, smaller machines can to be used to do diagnosis. This, in turn, results in a greater number of fail logs being diagnosed in a given day. Typically, the dynamic partitioning leads to a 5X reduction in memory and a runtime reduction of 50% per diagnosis report.

This dynamic partitioning technology makes a larger volume of scan diagnosis results available much faster, increasing the overall throughput of failure diagnosis by 10X. For existing Tessent Diagnosis users, setting up the dynamic partitioning flow is extremely easy. The benefits of dynamic partitioning include:

- Highly improved diagnosis throughput

- Reduced hardware resource requirements

- Enabler for volume diagnosis and yield analysis

Saving time and compute resources during volume scan diagnosis can confer a competitive advantage by reducing turn-around-time, equipment costs, and improving yield faster.

Watch Jayant D’Souza describe scan test, scan diagnosis, and dynamic partitioning in his Tech Talk with Semiconductor Engineering.