The quest for optimal DFT automation

End-to-End automation keeps DFT out of the critical path

IC design teams are always on the lookout for ways to make the flow more efficient, less expensive, and faster. They are driven by time-to-market demands and managing the increasing size and complexity of SoCs. One of the most successful changes in the design flow is taking a hierarchical, divide-and-conquer approach to design-for-test (DFT). The rapid deployment of hierarchical DFT flows in recent years has delivered real savings in test time and cost, and reduces design risk by keeping DFT out of the critical path to tape-out.

However, it turns out that retrofitting legacy flows with hierarchical methods can create new complexities and inefficiencies. For example, tracking setup information and tool configuration for different cores and levels of hierarchy requires a lot of manual intervention, which is tedious and can introduce errors.

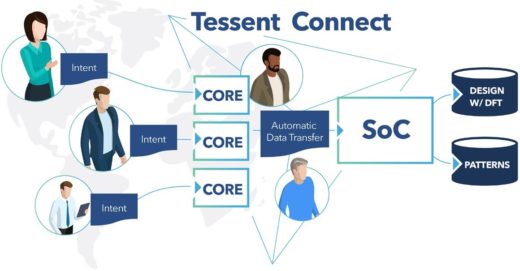

But now there is a production-proven solution to ease the adoption and implementation of hierarchical DFT flows. It helps by providing advanced, end-to-end automation that better connects the people, processes, and tools involved in the DFT work. The result is the creation of a reliable and sustainable flow that is both flexible and highly customizable. The solution is called Tessent Connect.

Challenges in adopting a hierarchical DFT flow

Most projects today use some form of hierarchical design in which cores are designed by different teams or individuals concurrently, then assembled and finished at the chip level. Hierarchical DFT uses the existing hierarchy of an SoC to insert all DFT and generate test patterns at the core level. The lowest level of hierarchy is the ‘core,’ which can be a single core or a group of cores. Some applications, such as AI chips, commonly group several smaller cores together for ATPG in order to share scan channels and minimize routing. Cores are isolated with core-level clocking and wrapper chains. All DFT insertion, verification, and pattern generation are performed at the core level. Patterns are retargeted to the chip level, where cores are represented by graybox models.

Legacy, flat DFT flows have been successfully translated to hierarchical flows, but it requires a lot of manual work. Typically, the designer has to describe every step the DFT tools should take and repeatedly input the same information to each step. It makes sense to introduce more automation to the DFT flow.

Tessent Connect end-to-end DFT automation

With Tessent Connect automation, designers can describe their intent rather than detailed commands. The universal test infrastructure enables a plug-and-play continuity across all the test instruments. With flexible and easy customization, the flow can be future-proofed against changes per design, designer, team, or company that occur.

We think of the elements of an optimal end-to-end automation for DFT flows in terms of three main categories:

- Intent-driven automation

- Universal test infrastructure

- Future-proof customization

These things together enable efficient concurrent design with easy hand-off between teams that reduces DFT time and increases predictability (Fig 1).

Intent-driven automation

What is intent-driven automation? It means that designers can describe the high-level test goals to the tool early in the flow rather than writing detailed, step-by-step scripts. For example, say you need to setup ATPG for different scan modes. Historically, the designer would have to write multiple scripts, keep track of the scripts and procedure files, and then load the correct setup files for each test mode. But now, all the scan configurations (internal, external, bypass mode, etc.) are inserted all at once and stored in a common database. Then, during ATPG, Tessent only needs to know which scan mode to import and it takes care of the details.

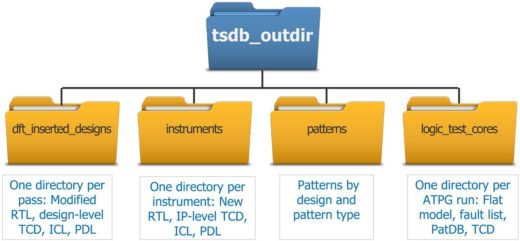

The common Tessent Shell database (TSDB) ends up being very important from a flow usability perspective. With this new automation, all the data and generated files are organized hierarchically in the database and called on throughout the flow as needed. (Fig 2).

The high-level DFT specification that captures the designer’s intent starts with a network to allow access and control of IJTAG-compliant on-chip resources. The specification guides memory BIST insertion (type, number, grouping, location), compression insertion (number and type of EDT controllers, chains per controller, locations), and much more. It also manages clocking control, power, and custom DFT signals and verifies that all the setups have no errors. It even generates the SDC files needed for physical design signoff.

Universal test infrastructure

Tessent Connect relies on IEEE 1687, IJTAG, infrastructure for plug-n-play automation across all test instruments, including third-party instruments. Using IJTAG-compatible IP significantly eases core and IP integration and reuse. It also allows the core-level test patterns to be retargeted to the next level up and to broadcast the patterns to identical cores.

The universal test infrastructure also simplifies the initialization procedures for a TAP controller. The cycle-by-cycle procedure creation process can be very time-consuming and error-prone. But now, it can be accomplished at a higher level of abstraction that enables automatic procedure creation through simple-to-use commands and built-in procedures.

Future-proof customization

Adopting a complete hierarchical flow from scratch might not be practical, so design teams need to be able to seamlessly integrate existing custom design steps and requirements into this new automation scheme. Tessent Connect allows a flow to be customized to perfectly suit individual users, groups, or company-wide requirements.

We refer to this as having multiple entry/exit points, and it welcomes custom and third-party tools. There are powerful introspection and Tcl scripting capabilities that can blend standard tool features and commands with user-defined commands and scripts.

Examples of future-proof customizations include:

- Create and automatically execute DRCs to check the status of enable pins on clock-gaters, check that memories are in bypass mode or enabled, check the slew rate of I/O pads, etc.

- Introspect design and tool data models

- Add a new user-defined attribute to track and fully introspect custom settings

- Change tool and user-defined attributes on any object type

Getting started with Tessent Connect end-to-end DFT automation starts with a flow assessment to review your current DFT goals, methodology, and flow. Complete reference flows, documentation, and test cases are also available to speed up adoption. No matter how much of the new automation is deployed, the results include a reduction in DFT implementation time and cost and a more efficient, predictable, and sustainable DFT flow.

For details on Tessent Connect, read the whitepaper Optimal End-to-End DFT Automation with Tessent Platform